- Home >

- Products

Top Products

-

PET Bottle Handle Plastic Injection Mould

Design and manufacturing of handle mould--- 1. Mold design of handle mold with 4 ~ 32 cavities. 2. Steel of mold cores and cavities is stainless steel with heat treatment. 3. Design of interchangeable die components for easy maintenance. 4. Specially designed nozzle and fast color changing hot runner system according to customer’s requirement. 5. All molds parts are machinery with CNC equipment.

Read More -

Baby Walker Plastic Injection Mould

In order to reduce the weight of baby walker, most of parts are made by plastic. On the other hand, plastic parts are stronger and colorful. Therefore, the quality of plastic parts of baby walker become very important. The key point of plastic injection mould for making baby walker is to get smooth surface and parting line to avoid injury against babies. Meanwhile, the assembly among of all plastic parts for baby walker is required flat without difference in level, prevent from collapse, enough strong and so on. It has to pay attention on the shrinkage of molds design and precise mold fabrication in order to get perfect assembly of baby walker, especially the small toy parts.

Read More -

Plastic Tea Bottle Cap Injection Mould

The general water bottles are round and sometimes take space in the bags, but these water bottles are square. If they are placed properly, they can save a lot of space inside your bag.

Read More -

Two-Color Pet Slow Feeder Bowl Plastic Injection Mould

Slow feed bowls tend to be simple designs that provide just enough of a barrier to slow your pup down. Puzzle feeders are great if your dog gets bored easily, regardless of their behavior at mealtime. By putting them to work for the reward of food, you get the double benefit of slowing them down while also providing a challenge that stimulates their mind.

Read More -

Kids Tricycle Plastic Injection Mould

The commonly used children's tricycle mould steels are 45#, 40Cr, P20, 2738, 2316, 718, NAK80, S136, etc. Generally, we suggest to use steel 718 and Shanghai Baosteel P20. Good mold structure design is the premise of a qualified mold manufacturing. The mold structure and product structure should be analyzed in all aspects, including mold draft angle, miniature of product surface, design of pouring system, design of exhaust system, design of cooling system, etc. The most important and most likely problems of these molds will be repeatedly tried in the mold structure design Proven.

Read More -

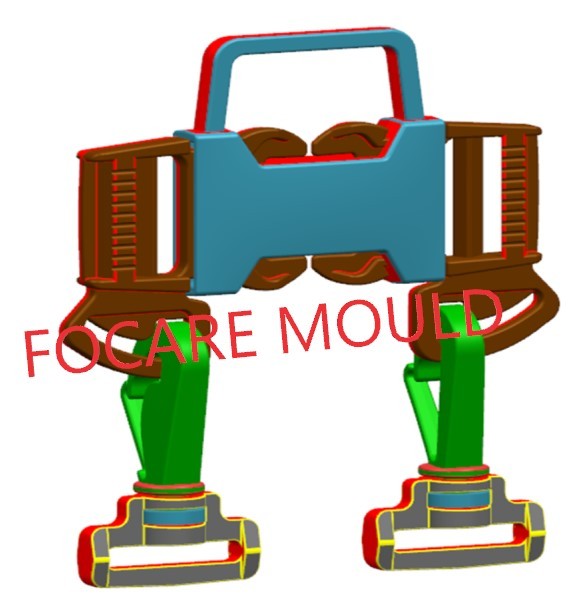

Plastic Buckle of Five-Point Safety Belt Injection Mould

Actual accidents include various collision situations: Frontal collisions, side collisions, rear-end collisions, and overturns or all of the above collisions exist simultaneously. Child safety seats need to be designed to meet all of the above crash requirements to provide proper protection. 1. Five-point safety belt can dissipate the force generated by the impact in 5 directions at the same time, transferring external force from the child. 2. The process of dissipating power by a five-point seat belt is to minimize the accumulation of power and avoid greater harm. 3. The high-performance shoulder pad can effectively absorb the huge impact force, while its anti-slip properties reduce the baby's forward and head displacement and avoid head injuries. 4. The five-point safety belt can be continuously adjusted according to the baby's body size, thereby protecting the baby more closely and comprehensively. 5. In the safest state, ensure that the baby has enough space for movement. At the same time, the baby cannot open the buckle on its own, making parents more at ease.

Read More -

Plastic Foldable Two-Color Stepping Stool Plastic Injection Mould

The foldable stool is composed with night components, six sides, two tops and non-slip feet, which are made by four molds only. The six sides are manufactured by two moulds, non-slip feet is made by one mold with TPE plastic material. The top sides generally are made by double color injection which looks high end and more colorful and beautiful. It is produced by one double color injection mould of PP + TPE or two single colors mold for making PP and TPE separately. TPE is soft material which is not only well tough, but also for skid proof when this folding stool is used for stepping at bathroom or kitchen.

Read More -

Toilet Seat and Lid Plastic Injection Mould

The total weight of the whole set plastic toilet seat is 650 gm, made by PP. The two plastic injection moulds of main body are made 1 cavity with one tip hot runner. As for the rest of the components we apply cold runner and 4 cavities. Seven moulds plus a 125 and 350 ton plastic injection machine is sufficient to manufacture a plastic toilet seat, which is really a good investment while the toilet seat is so high demand on markets.

Read More -

Plastic Portable Tool Box Injection Mould

1. PP engineering plastic, good bearing capacity, beautiful appearance, strong plasticity, various colors, large internal volume of portable toolbox. 2. The worktable adopts unique injection molding, with higher strength and smooth surface treatment, it is easy to wipe oil stains. The injection panel can bear the bench vice operation 3. Abundant tool modules can be stored in the drawer of toolbox 4. Sliding guide rail design is adopted on both sides of drawer, which has excellent smoothness and improves service life. The extended distance enables the drawers to be fully opened, making it easy to extract the objects inside the drawers. 5. Each drawer has self-locking function 6. It is suitable in size and can be stored in the trunk of the car. It is convenient. Toolbox of different sizes can be built in together.

Read More