- Home >

- Products

Top Products

-

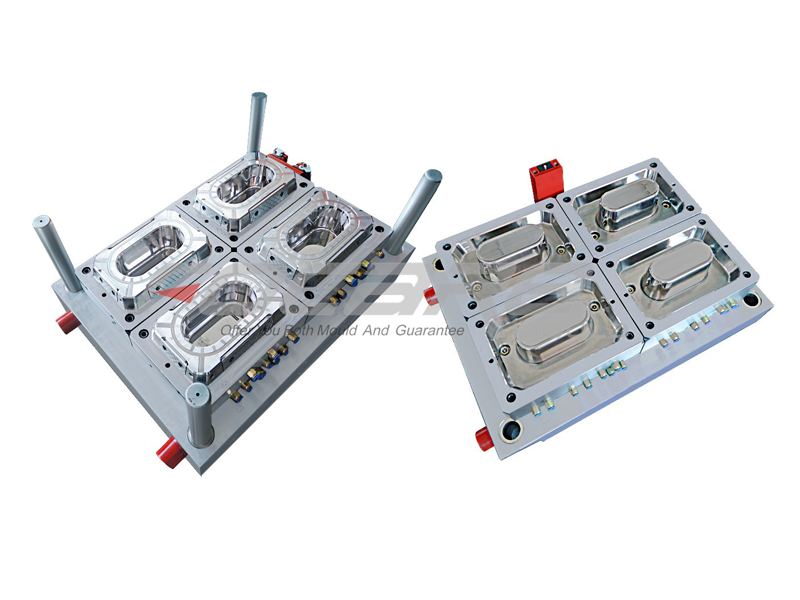

IML Container Molds

The advantage of IML process are as below: 1. Excellent product presentation is the main advantage of IML technology. Preliminary preparation of the label allows to use full-color printing with clear graphics and realistic image. 2. The IML product is one object - the label does not exfoliate. 3. The process of applying the label is combined with the packaging process. 4. The label provides stronger adhesion to the product itself, which facilitates packaging and storage. 5. Automatic protection against counterfeiting is automatically achieved, as IML technology is generally owned by fairly large manufacturers who will not participate in pirated production. 6. If necessary, changes in design are made quickly. 7. Low cost labels compared to traditional one.

Read More -

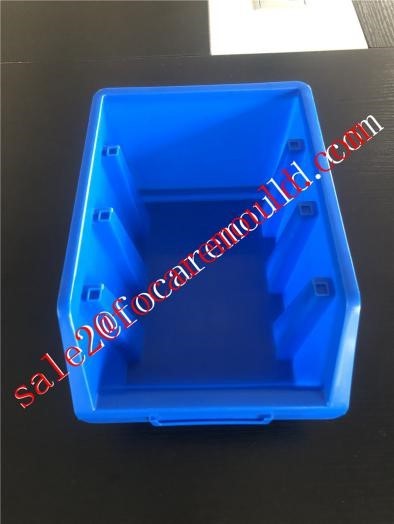

Plastic Modular Bevel Storage Box Injection Mould

This modular bevel storage box has the characteristics of folding resistance, anti-aging, high loading strength, stretching, compression, tearing, high temperature, rich color, lightness, durability and stacking. We can make molds for all kinds of specifications and sizes according to the user's requirements, which can be capped, dust proof and beautiful in appearance. The features of mold design are as below: 1. The cavity is made with insert part which is to process and maintenance in future. 2. Stripper plate for balancing ejection. 3. The protruding part of plastic box is used as the insert, which can release and exhaust the air, making it easier to eject the product. 4. High efficient cooling circular design for shortening cycle time. 5. Excellent NC processing to increase the assembly precise of mold to reduce flash.

Read More -

1L Juice Blender Plastic Injection Mould

For this juice mixer mold, the most important point is the high-end polish. The mold should be polished carefully to reach high transparency. As there are two big sliders to form the part, the parting line on the handle part is important, too. The parting line should be as less as possible to avoid flash and cutting customers’ fingers while using.

Read More -

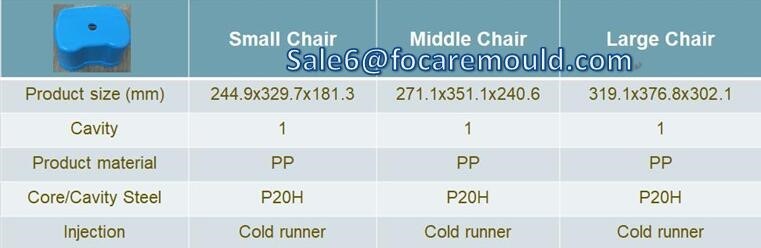

Multi Purpose Plastic Stool Injection Mould

The important points which we care about when we make chair molds: 1) We add as many cooling system as possible including the chair surface to ensure outstanding cooling performance. 2) We add wear plates with 45HRC above to guarantee the chair molds’ life. 3) We use steel with 30-33HRC. 4) We use high speed CNC machine to reach 0.02 mm precision.

Read More -

3pcs Seasoning Box Condiment Storage Containers Plastic Injection Mould

The two moulds have no special design, but they require the technique of processing steel. In this case, we make inserted core for better processing and easier to repair, fine handle part that has no flash to prevent customer’s hands being scratched, and well-polished cavities and cores for high quality of appearance. Focare Mould, we own sets of high accuracy CNC machine, which is our proud that owning the capability of manufacturing high quality plastic injection moulds. Provide plastic injection mould with the highest CP value and create a win-win has always been our target.

Read More -

Straw Handle Cup Plastic Injection Mould

This straw handle cup is divided into two sets of molds, one is the cup body and the other is the cup cover. In design, the cup body cavity 2 spring block slides. When opening the mold, it depends on the pull hook on the mold core side to start in an instant, and then the spring pushes the spring block out, and the mold core side directly relies on the machine to push the ejector plate to eject the product and drop. When the cup cover is opened, slide the 2 sliding blocks on one side of the core to both sides through the inclined guide post to separate the sliding blocks from the product. The 2 sliding blocks are designed on the pusher plate to eject the product as a whole.

Read More -

16 Holes Plastic Dish Rack Injection Mould

DISH RACK 16 HOLES Product Size: 489 x 489 x 100mm Mold Design: 1. Cavity and Core made by splicing inserts 2. High-efficiency cooling system 3. 4 sliders design for Core with oil cylinders 4. Runner Gate with 5 tips Hot Runner to Submarine Gate

Read More -

Plastic Grater Injection Mould

Grater Size: 229 x 146 x 80 mm Type: Cheese, Fruit & Vegetable Tools Material: Food-grade PS and PP Fruit & Vegetable Tools Type: Graters Function: Grinding mud. Grinding paste. Suitable for the elderly and children 1. Simple mold design for easy maintain 2. The independent core pin for holes. 3. Ejection system: Stripper Plate and achieve a 360 degree air blast to avoid vacuum condition after injection.

Read More -

Threaded Cap Plastic Injection Mould

Cap size: ø90.7 X 93 X 25mm Cap weight: 36gm Material: HDPE Mold: 4 cavities The thread part of this cap is designed with thread rotation off, and the motor device is used to drive the gear to rotate. The cap must be designed with a stop device to prevent the product from following the rotation when the thread rotates, resulting in the scratch of the cap thread. After the thread part of the cap is separated, use the ejector plate to eject. Compared with thread strength and thread rotation, thread rotation is more difficult to make, which requires high-precision processing equipment, high installation accuracy and accurate positioning between plates, otherwise it is easy to cause the problem of parts stuck and motor or oil cylinder not moving.

Read More