- Home

- >

- Products

- >

- Kitchenware Mold

- >

- 1L Juice Blender Plastic Injection Mould

1L Juice Blender Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

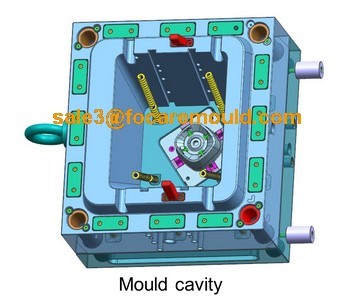

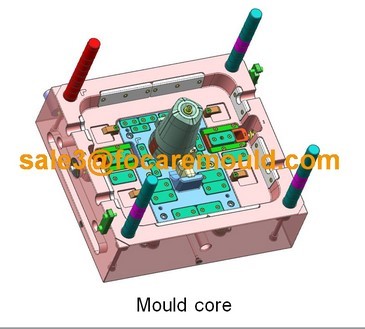

For this juice mixer mold, the most important point is the high-end polish. The mold should be polished carefully to reach high transparency. As there are two big sliders to form the part, the parting line on the handle part is important, too. The parting line should be as less as possible to avoid flash and cutting customers’ fingers while using.

PS plastics have many excellent properties, such as high transparence, low moisture absorption, solvent resistance, chemical stability, strong mechanical properties and so on, and are widely used in the fields of electronics, machinery, automobile industry, medical treatment and so on. But there is also food-grade PS, such as fast food boxes, food packaging boxes, and instant noodle filling boxes and so on.

For example, this juice mixer, the main body is made from food grade PS which is much better than food grade PP. Because PS is very transparent and PP looks like the feeling of ground glass. Besides, PS material is relatively hard, while PP material has good toughness and insufficient hardness. Generally PS products are thicker than PP products.

So for the main body of juice mixer, using food-grade PS is a good choice. It's transparent. While mixing the juice, we can clearly see the amount of food put in and the mixing situation.

In addition, the PS material is much lighter than glass, the consumers can use it more conveniently and easily. Moreover, PS plastic has good low temperature resistance, its embrittlement temperature is - 30 degrees Celsius, so it can be used in the environment of minus 20 degrees Celsius, so there is no safety problem when we add ice when mixing.

The small cap on the lid can be used as a counting cup, which can prevent juice overflow when stirring, or add ingredients without opening the lid in the stirring process.

For this juice mixer mold, the most important point is the high-end polish. The mold should be polished carefully to reach high transparency. As there are two big sliders to form the part, the parting line on the handle part is important, too. The parting line should be as less as possible to avoid flash and cutting customers’ fingers while using.