- Home >

- Products

Top Products

-

Plastic Portable Tool Box Injection Mould

1. PP engineering plastic, good bearing capacity, beautiful appearance, strong plasticity, various colors, large internal volume of portable toolbox. 2. The worktable adopts unique injection molding, with higher strength and smooth surface treatment, it is easy to wipe oil stains. The injection panel can bear the bench vice operation 3. Abundant tool modules can be stored in the drawer of toolbox 4. Sliding guide rail design is adopted on both sides of drawer, which has excellent smoothness and improves service life. The extended distance enables the drawers to be fully opened, making it easy to extract the objects inside the drawers. 5. Each drawer has self-locking function 6. It is suitable in size and can be stored in the trunk of the car. It is convenient. Toolbox of different sizes can be built in together.

Read More -

Double Color Plastic Fruit Bowl Injection Mould

Most of customers don’t want to invest double color injection machine. However, you can consider to produce two plastic products on your double color machine in future, or produce only one plastic part on double color machine. It won’t leave your double color injection machine unused if double color products range has not yet been developed too much. Two-color plastic injection products become more popular at market day by day, it is right time to invest and develop double color plastic products at this moment.

Read More -

Double Color Drinking Cup Plastic Injection Mould

Double color molding process is that the two-color products are moulded by one double color injection machine and two-color mold at once, the double color product is only ejected once. Generally, this molding process is also called two-component injection molding, which is usually completed by a set of molds and requires a special two-color injection molding machine. Plastic products are used two different color, two different types of plastics or two identical plastics, and the two plastics can be clearly distinguished on the product are called two-color plastic products. Installed in a two-color injection molding machine with two sets of injection devices, a mold that injects two plastics in sequence and generates a two-color product is called a two-color mold.

Read More -

Plastic Industrial Safety Helmet Injection Mould

Industrial safety helmets are widely used on building and workshop to protect the head from injury due to falling objects, impact with other objects, debris, rain, and electric shock. For making plastic industrial safety helmets, PC or ABS plastic material are the best selection which has the best impact resistance, light weight, high toughness, less fracture, and easy processing.

Read More -

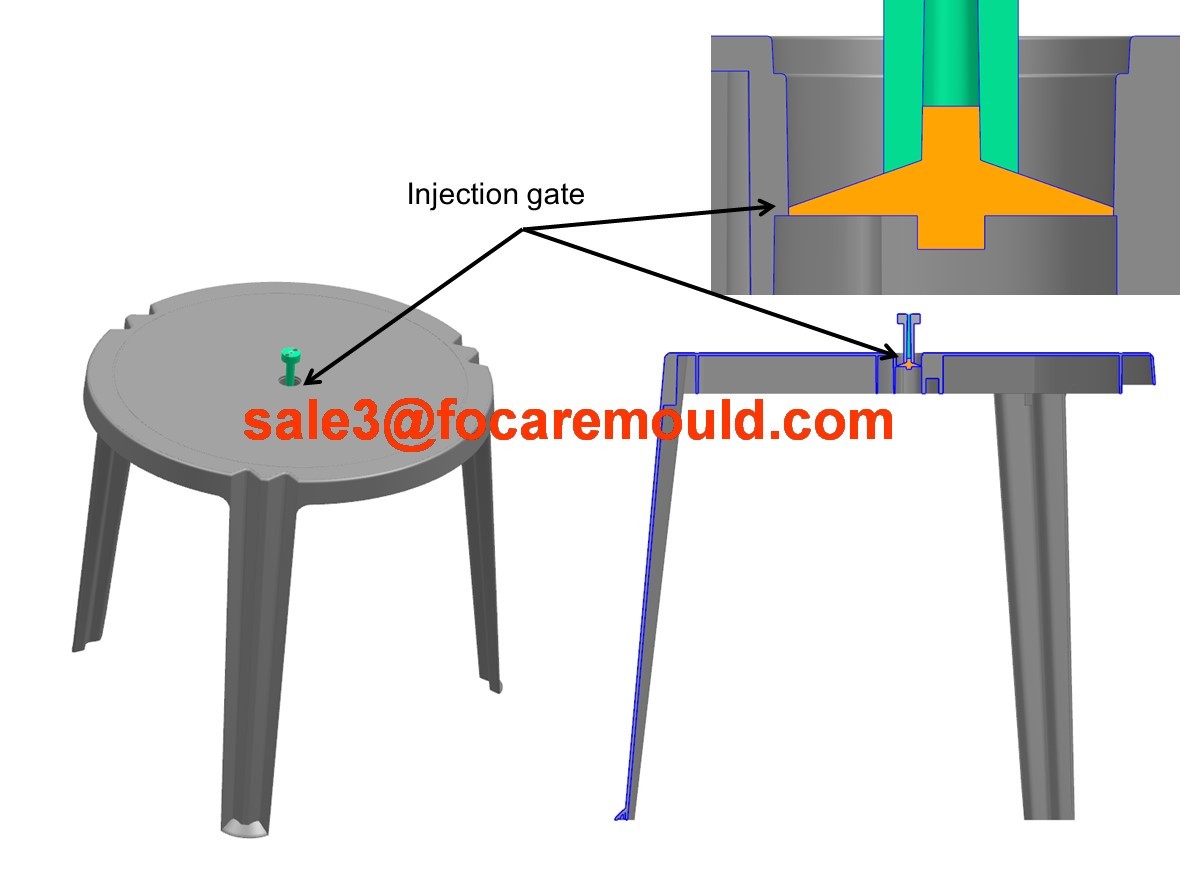

Plastic Garden Table Injection Mould

Traditional plastic injection tables have separated table legs. This means that the table top and the table legs are separate. In this way, we not only need to have extra mold for the table legs, the strength of the entire table will be weakened by the separate table legs. This plastic outdoor table is one-piece. The strength of the table is much stronger than separated tables. Besides, you don’t need to pay for extra leg mold.

Read More -

Swing Cover of Dustbin Plastic Injection Mould

The acceptable checking list of swing cover of dustbin are as below: 1. Cover shall be flat without deformation. 2. Cover of trash bin shall align the same level with cover supporter. 3. Cover shall come back original position automatically after swinging. 4. Cover be rotated evenly. 5. Supporter of cover is prohibited being deformed after ejecting out from mold cavity and cooling. 6. No flash around supporter.

Read More -

Plastic Electrical Junction Box Injection Mould

ABS Plastic Dustproof Waterproof Junction Box Universal Electrical Project Enclosure White 11.8" x 9.8" x 4.7"(300mmx250mmx120mm) The features of mold design are as below: 1. There are perforations on the 4 sides of the product; therefore, the cavity needs a small mold opening. 2. The 4 sides of the I-shaped drive the 4 sides of the slider to pull the core. 3. For the mold of the cover, in order to make the product look beautiful, the anti-adhesive is designed so that the product is firmly on the side of the fixed mold. 4. Simple mold design for easy maintain 5. On the side of the core, insert the insert inside and eject it with a thimble.

Read More -

One-Piece Lid of Peper Can Plastic Injection Mould

This one-piece flavor lid is designed as 45 degree for kid-friendly extension and high-quality display. The size of the product is 46.5*54.5mm, the weight is 16g and the material is ABS. Not only is the product unique, the mould is also impressive. This is a classic plastic injection mould that gathers 4 most common mould structures. To manufacture the product we apply: Sliders, Exchangeable inserts, Core pulling, and unscrewing device. The complete mould action will be introduce in sequence:

Read More -

Spray caps of Insecticide Plastic Injection Mould

Spray cap molds are used in the molds for producing insecticide shells. They are made in accordance with the shape of the insecticide cover required. They are injection molded with plastic and processed into insecticide shell parts through various processes. The principle of the spray tank is that the liquid is pressed out of the valve by using air pressure. The liquid can be sprayed evenly. The direction and dose can be controlled. Any content can be easily put in and easy to use.

Read More