- Home

- >

- Products

- >

- Kitchenware Mold

- >

- One-Piece Lid of Peper Can Plastic Injection Mould

One-Piece Lid of Peper Can Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

This one-piece flavor lid is designed as 45 degree for kid-friendly extension and high-quality display. The size of the product is 46.5*54.5mm, the weight is 16g and the material is ABS.

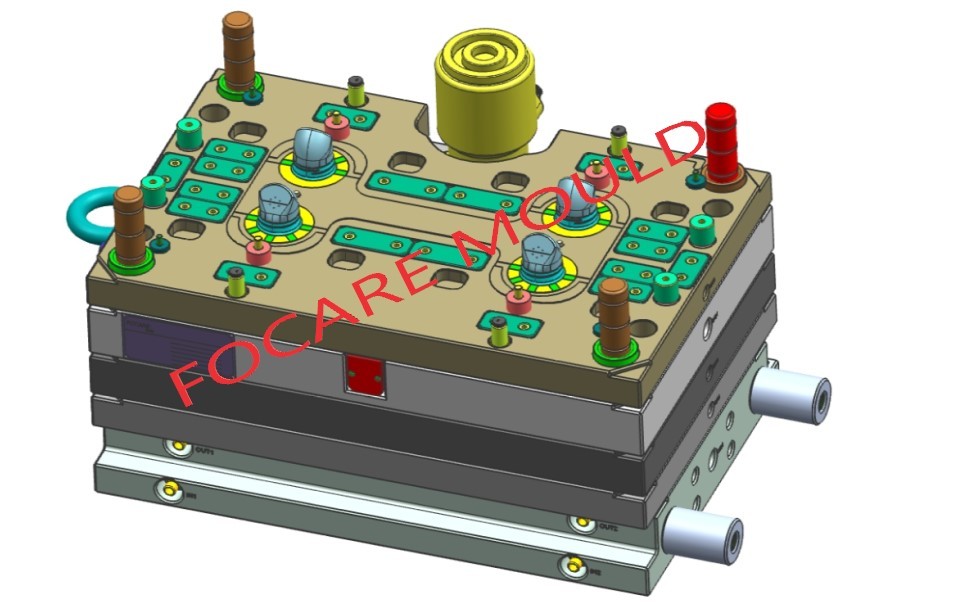

Not only is the product unique, the mould is also impressive. This is a classic plastic injection mould that gathers 4 most common mould structures. To manufacture the product we apply: Sliders, Exchangeable inserts, Core pulling, and unscrewing device. The complete mould action will be introduce in sequence:

This one-piece flavoring lid is designed as 45 degree for kid-friendly extension and high-quality display. The size of the product is 46.5*54.5mm, the weight is 16g and the material is ABS.

Not only this cover of pepper can is unique, the mould is also impressive. This is a classic plastic injection mould that gathers 4 most common mould structures. To manufacture the product we apply: Sliders, Exchangeable inserts, Core pulling, and unscrewing device. The complete mould action will be introduce in sequence:

First Step – Mould closing and material Injection

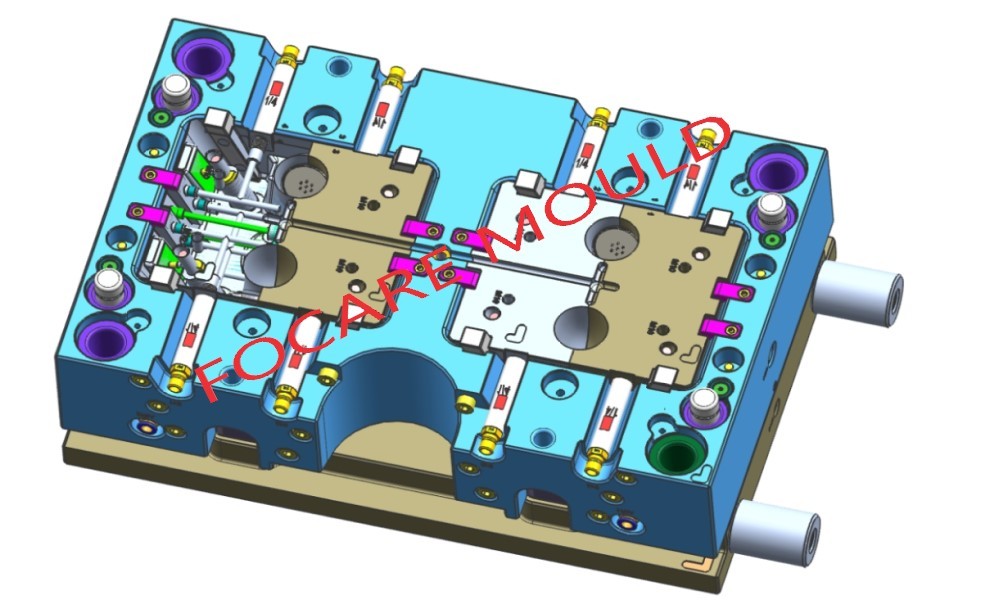

Second Step- Core pulling: Pull out the core for the holes part.

The direction of mould opening and holes on the lid is not horizontal, it will scratch the products when the mould is opening. To solve the problem, we make the holes with cores that can be pulled out before ejection.

Third Step - Sliders: Open the sliders that surrounded products.

Due to the shape of one-piece flavor lid is curved, it can’t be ejected out directly. In this case, we designed 2 sliders that will open before product being ejected.

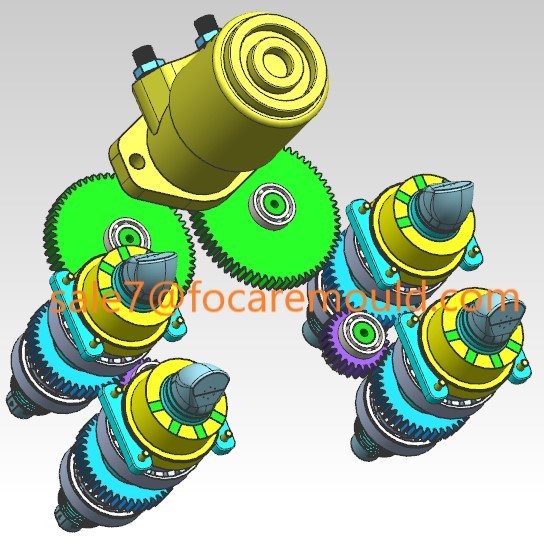

Fourth Step - Unscrewing device: Unscrew the rods and make a thread.

Through the screwing of gears drive the rods to rotate and create a thread for products. It is a complicated device that needs careful calculation on distance and gear adoption.

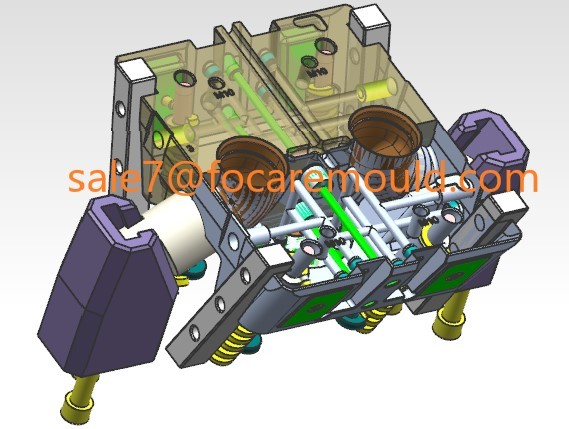

Fifth Step - Product ejection.

Connect the ejector rods with plastic injection machine to drive the stripper plate and ejector pins for product ejection.

Sixth Step - Exchangeable inserts: Change inserts for different types of products.

For the one-piece flavor lid plastic injection mould, adopting exchangeable inserts for the mould allows manufacturer to produce products with different types. For example, the lid for pepper, salt or other ingredient which require different size of holes. Besides, another excellence of the design is the convenience of fixing the part that likely to damage. Instead of remaking the mould cavity or core, we may replace the broken insert only.

The one-piece flavor lid plastic injection mould is really complicated that full of many structures. Focare Mould, we have years of experience on design, process, technique, and with the precise equipment that allow us to make the mould as delicate and attentive as possible.

The advantage of mold design is that you can combine 3 molds into one mold, saving at least 50% of the mold cost! Others ask you to spend, we teach you to save. We are proud to say that we are very strong in making this precision mold structure!