-

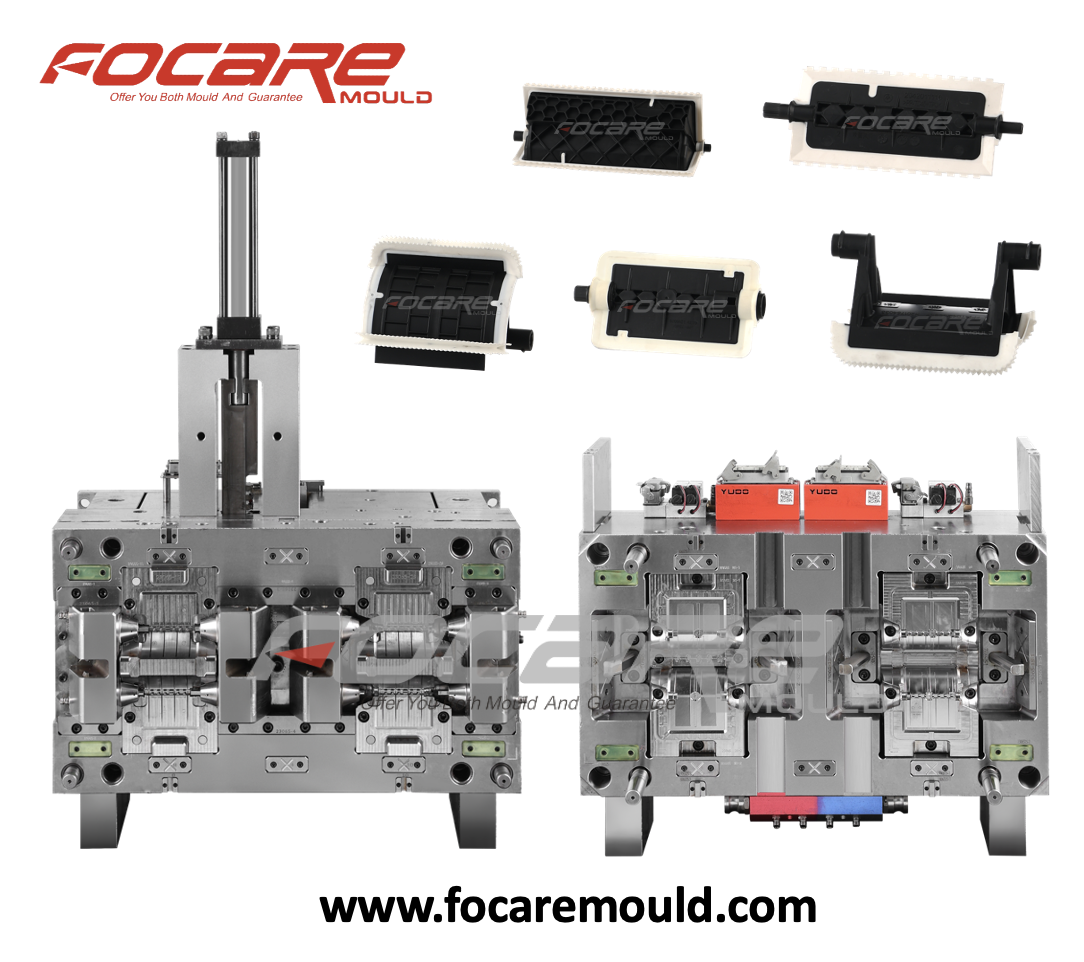

Two color car parts HVAC flap mold

Product material :PP+TPE Mold cavity: (1+1)+(1+1) Mold steel:718 with hardness 30-33HRC Injection system: 6tips valve gate hot runner

Read More -

Two color automotive parts AC flap mold

Product material :PP+TPE Mold cavity:1+1 Mold steel:2738 with hardness 28-33HRC Injection system:4tips valve gate hot runner Mold size:900X600X500mm Suitable machine: 250ton-280ton two color injection molding machine

Read More -

Car Side Mirror Plastic Injection Mould

The features of mold design for car mirror are as below: 1. The smooth appearance is very important for car parts. It is prohibited to have any gape among of all assembly parts, hence, the shrinkage ratio is key-point on making mold design. 2. The sliders shall be finished by automatic machinery to ensure the accurate dimension. Meanwhile, the moving position of sliders shall be very stable and precise in order to avoid flash or lines. 3. In order to avoid scratching of texture, the ejecting angle shall be 5 degree above. 4. The plasticizing material flow will influence the surface of car mirror. The plastic material flow channels will be affected by structure of injection runners. Meanwhile, the runner will be the factors of cycle time and material consumption.

Read More -

Double Color Car Light Plastic Injection Mould

The two-color mold technology uses multiple materials for injection molding production, and combines the characteristics of different materials during the molding process to assemble or other suitable bonding methods to improve product functionality and aesthetics. Automotive lights in two-color molds are an important application area. The features of double color car lights molds are as below: 1. The moving side of double color molds will be rotated by rotary table of double color injection machine. Hence, car lights shall be fixed on moving mold well to avoid being stuck in cavity side. 2. The fixing position after mold rotation shall be very precise, hence, the rotary table of injection machine shall be driven with servo motor instead of hydraulic motor. 3. Injecting stroke shall be designed as shorter as possible in order to enhance the strength of ejecting rod.

Read More