- Home

- >

- Products

- >

- Plastic Automotive Car Parts Mold

- >

- Two color automotive parts AC flap mold

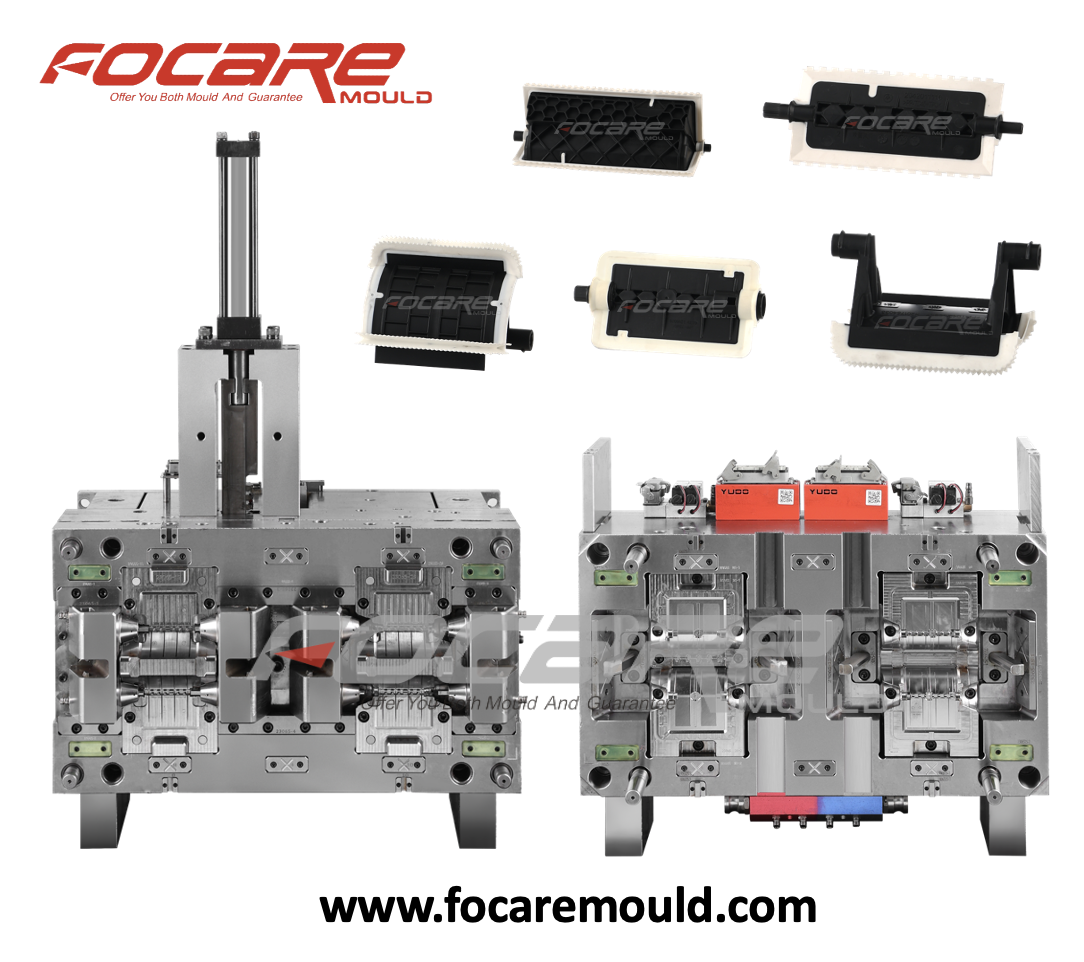

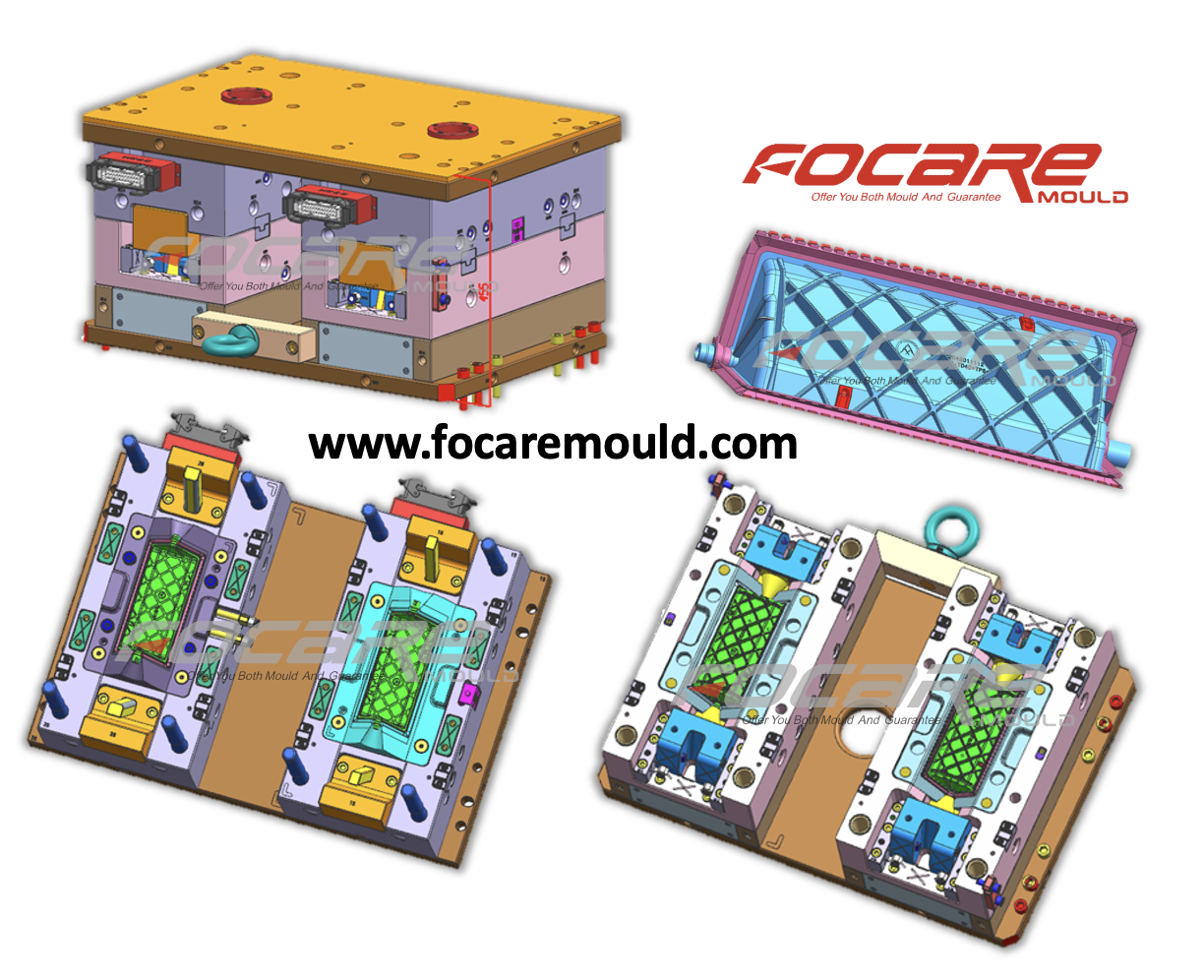

Two color automotive parts AC flap mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

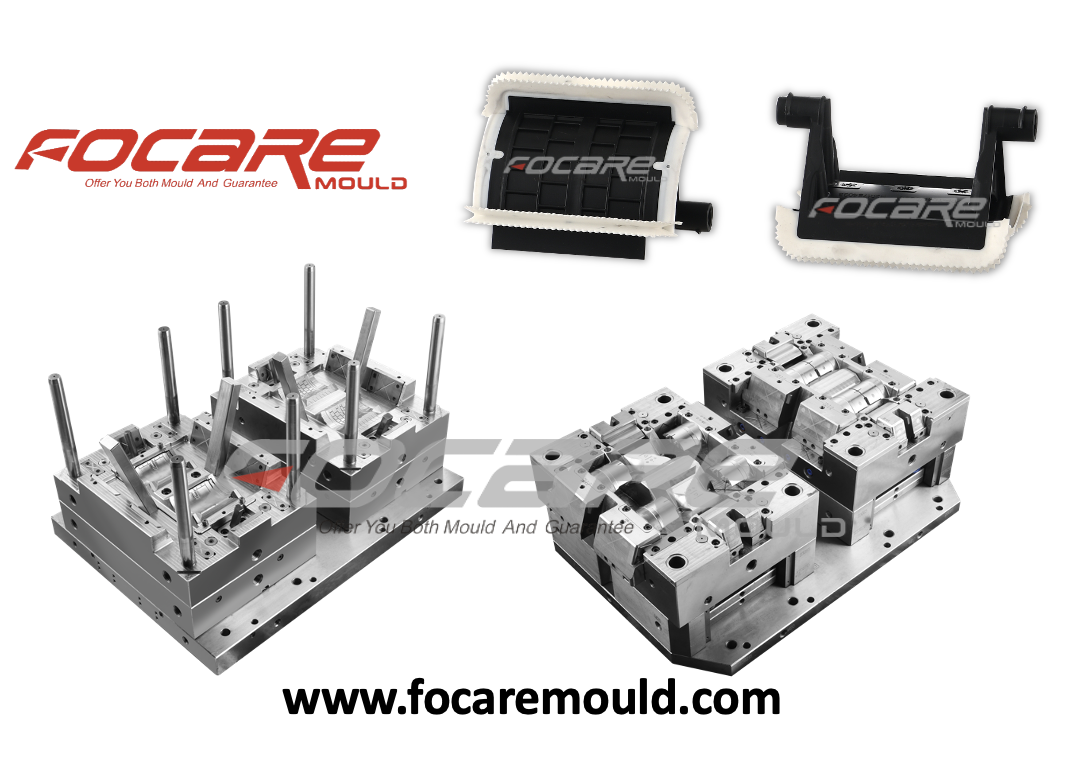

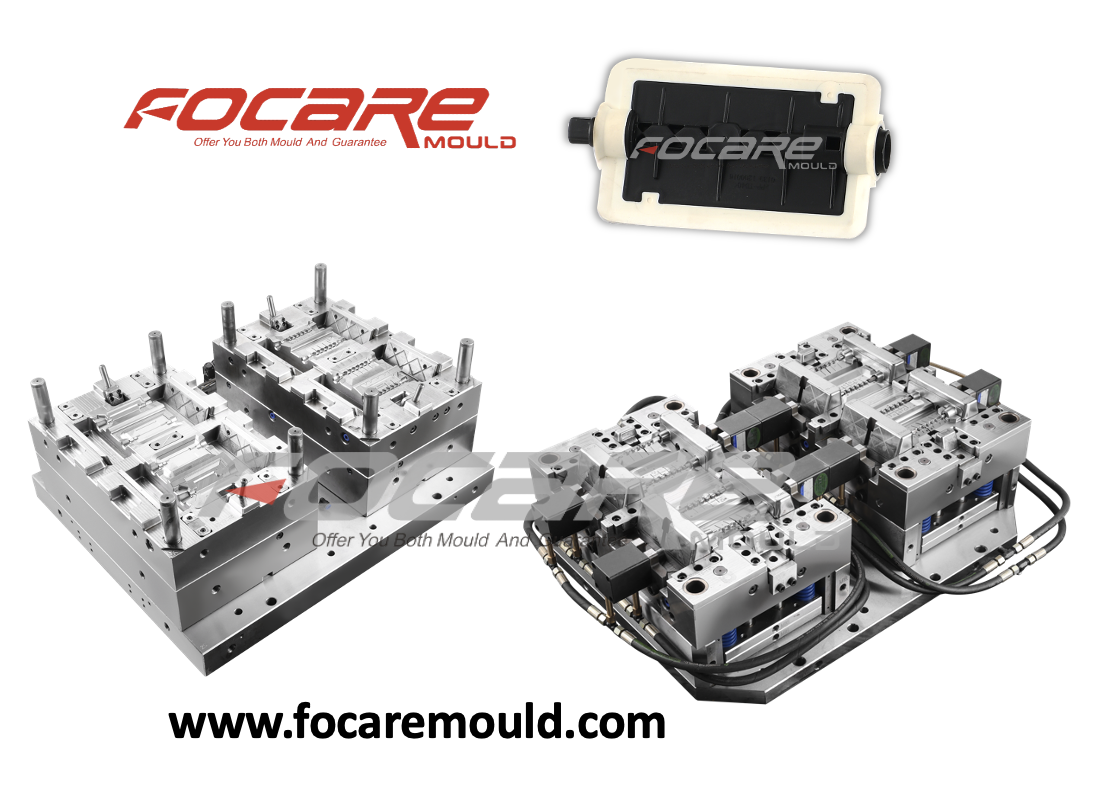

Product material :PP+TPE

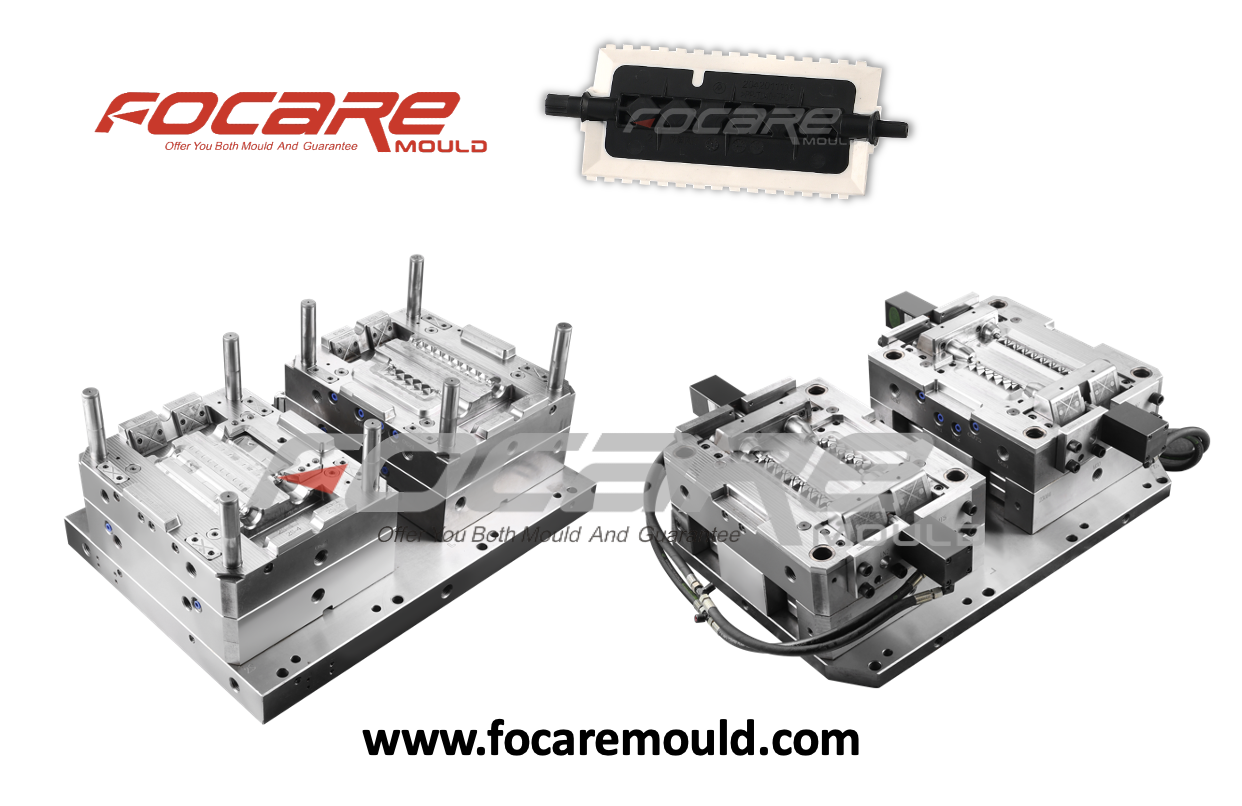

Mold cavity:1+1

Mold steel:2738 with hardness 28-33HRC

Injection system:4tips valve gate hot runner

Mold size:900X600X500mm

Suitable machine: 250ton-280ton two color injection molding machine

Detail information of two color 2k automotive parts AC temperature partition flap plastic injection mold

Two color 2k automotive parts AC temperature partition flap plastic injection mold

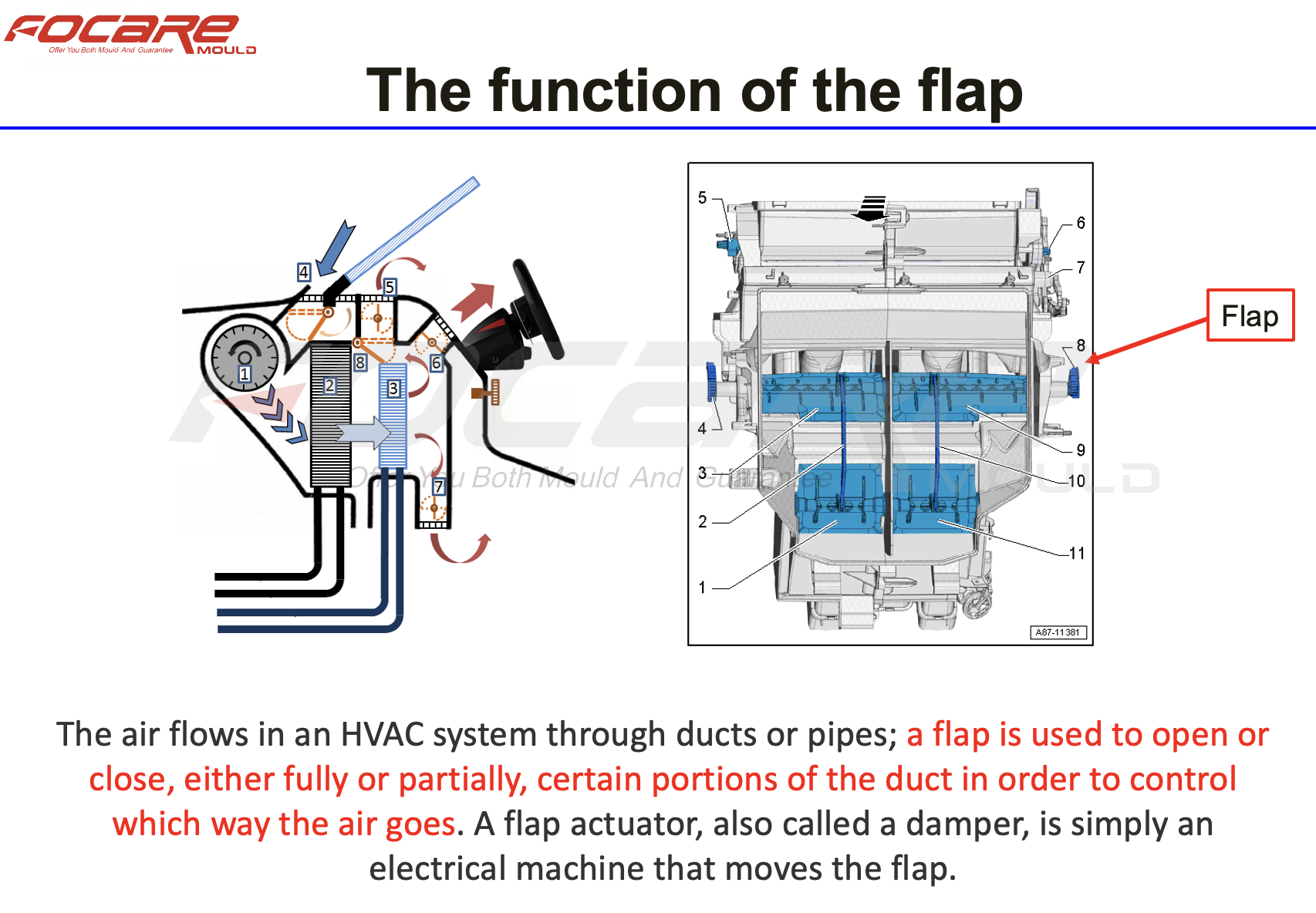

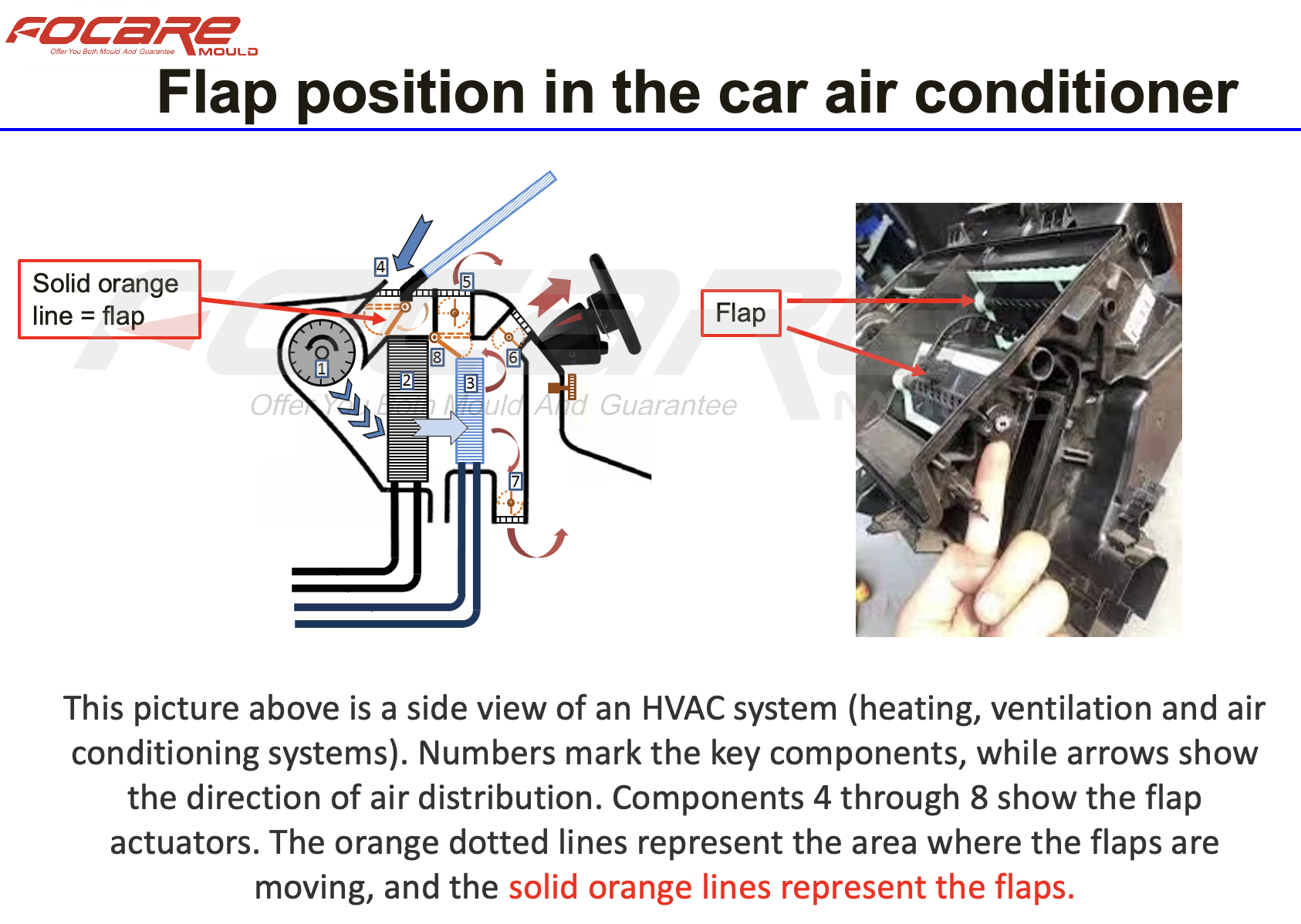

The function of the 2 component HVAC temperature partition flap

The air flows in an HVAC (heating, ventilation and air conditioning) system through ducts or pipes; a flap is used to open or close, either fully or partially, certain portions of the duct in order to control which way the air goes.

A flap actuator, also called a damper, is simply an electrical machine that moves the flap.

This picture above is a side view of an HVAC system (heating, ventilation and air conditioning systems).

Numbers mark the key components, while arrows show the direction of air distribution. Components 4 through 8 show the flap actuators.

The orange dotted lines represent the area where the flaps are moving, and the solid orange lines represent the flaps.

Each vehicle HVAC module has six primary components: Evaporator, Heater Core, Blower Assembly, Actuators, Sensors and Filters. Vehicle air conditioner moulds are necessary for HVAC housings, covers and doors.

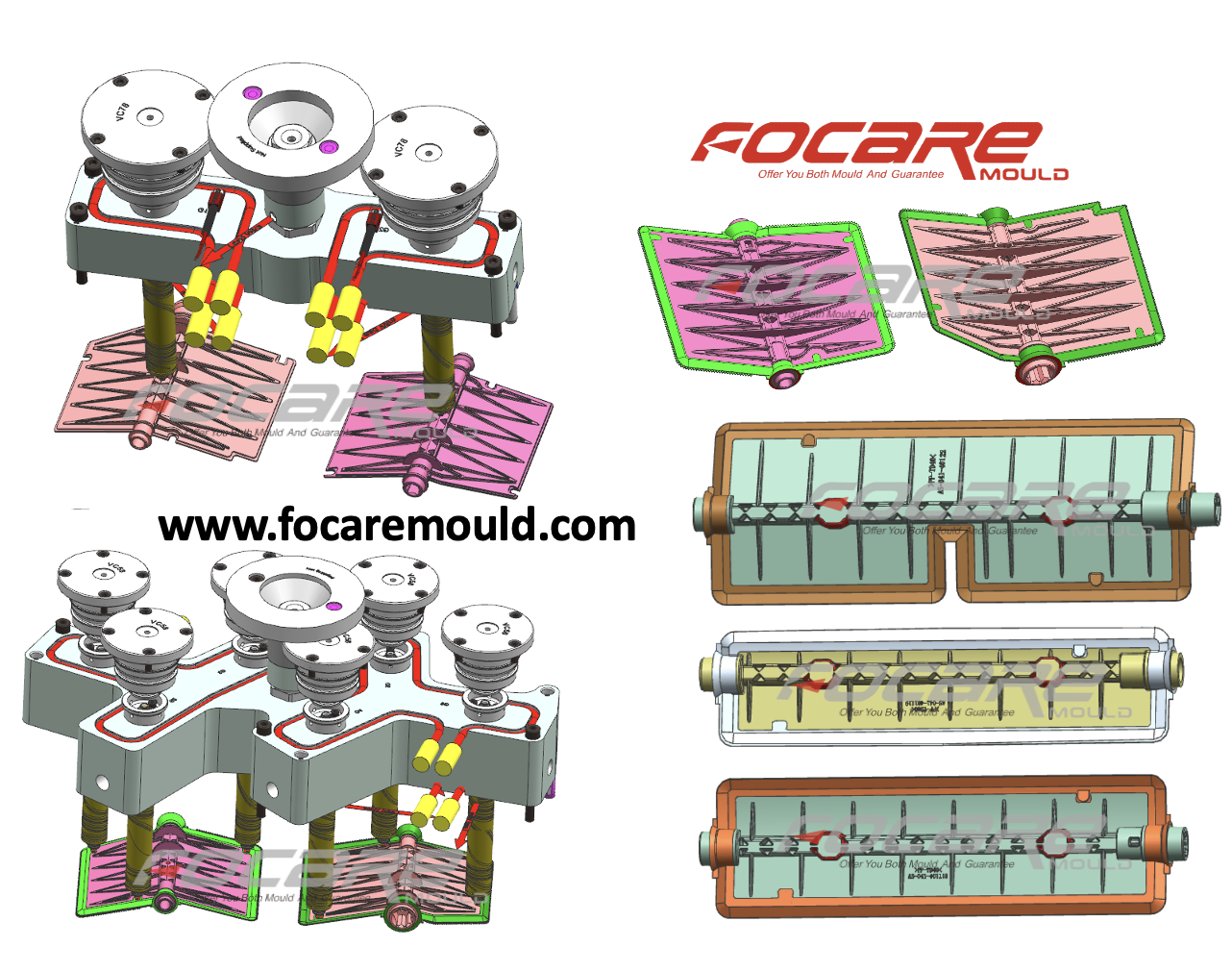

Focare Mould has rich experience in the field of car air HVAC molding.

We have a professional product and mold desgin team to help you develop your project with 2k bi material automotive part HVAC temperature partition flap.

Focare Mould is China professional multi shot mold manufacturer,china mold maker, multi shot injection molding expert.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services