- Home

- >

- Products

- >

- Plastic Automotive Car Parts Mold

- >

- Car Side Mirror Plastic Injection Mould

Car Side Mirror Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

The features of mold design for car mirror are as below:

1. The smooth appearance is very important for car parts. It is prohibited to have any gape among of all assembly parts, hence, the shrinkage ratio is key-point on making mold design.

2. The sliders shall be finished by automatic machinery to ensure the accurate dimension. Meanwhile, the moving position of sliders shall be very stable and precise in order to avoid flash or lines.

3. In order to avoid scratching of texture, the ejecting angle shall be 5 degree above.

4. The plasticizing material flow will influence the surface of car mirror. The plastic material flow channels will be affected by structure of injection runners. Meanwhile, the runner will be the factors of cycle time and material consumption.

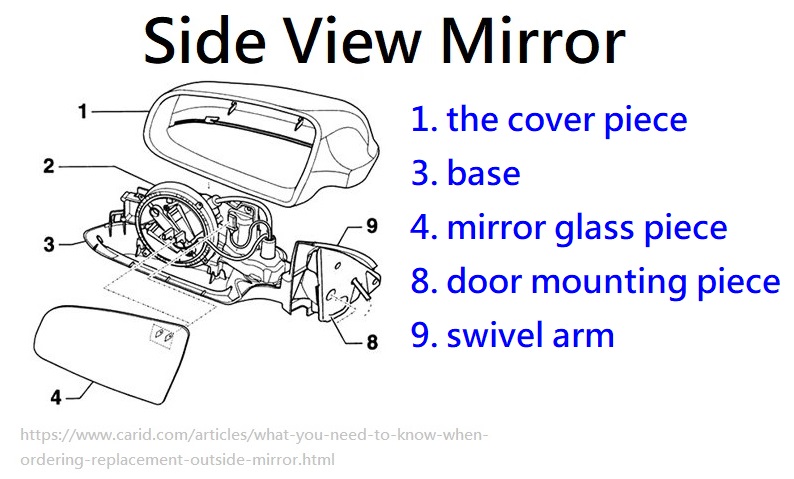

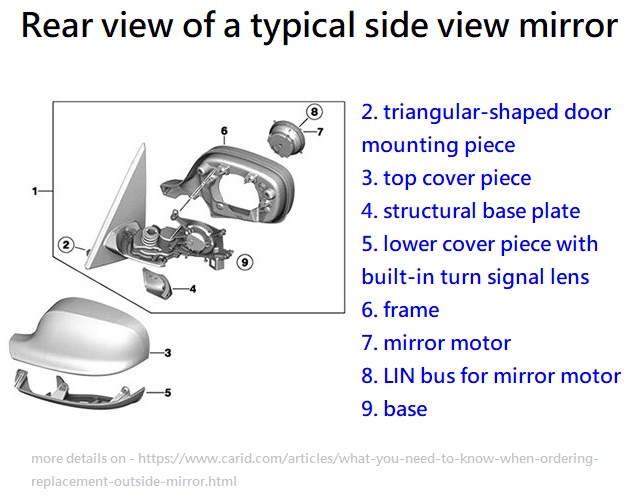

Car side mirror is composited by mirror frame, base, housing, supporter, swivel arm and so on. The surface quality of car mirror housing is critical, it generally is micro-texture for premium cars, coating for normal cars. According to car design, car mirrors are sorted into split one and integral type.

1. The cover piece

1) Plastic Material: ABS

2) Cavity: 1R+1L

3) Injection gate: 1 hot runner tip transfer to color runner

2. Base:

1) Plastic Material: PP+GF45

2) Cavity: 1R+1L

3) Injection gat: Cold runner or side gate from 1 hot runner

3. Supporter of cover

1) Plastic Material: ABS

2) Cavity: 1R+1L

3) Injection gat: 1 hot runner tip transfer to color runner

4. Swivel arm

1) Plastic Material: ABS

2) Cavity: 1R+1L

3) Injection gat: 1 hot runner tip transfer to color runner

5. Frame of mirror

1) Plastic material: ABS

2) Cavity: 1R+1L

3) Injection gat: 1 hot runner tip transfer to color runner

The features of mold design for car mirror are as below:

1. The smooth appearance is very important for car parts. It is prohibited to have any gape among of all assembly parts, hence, the shrinkage ratio is key-point on making mold design.

2. The sliders shall be finished by automatic machinery to ensure the accurate dimension. Meanwhile, the moving position of sliders shall be very stable and precise in order to avoid flash or lines.

3. In order to avoid scratching of texture, the ejecting angle shall be 5 degree above.

4. The plasticizing material flow will influence the surface of car mirror. The plastic material flow channels will be affected by structure of injection runners. Meanwhile, the runner will be the factors of cycle time and material consumption.