- Home >

- Products

Top Products

-

Plastic Kitchen Utensils Injection Mold

Most of the materials for kitchen utensils are PA. PA has good comprehensive properties, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubrication, and has a low coefficient of friction. The reason is that it makes it easy for people to grab it and put it back in place. It also condenses the space of the cutlery box and provides decoration for the kitchen interior design, thus creating a delicate design for the kitchen.

Read More -

Two-color Plastic Portable & Collapsible Bathtub Injection Mold

By simply just follow the under four steps to do before or after using it: - turn the bathtub up or upside down - pop-up or fold with hand press - restore or remove the leg supports - turn it up for using. After using, turn it over and put it away

Read More -

Two-Color plastic Lighter handle Injection Mould

Most two-color lighter handles are made from plastic injection molds with rotating shafts. The rotating shaft process or the rotating core process means that the two-color plastic injection mold is not rotated by the injection molding machine, but the core is rotated by the injection molding machine or the injection mold cylinder. When the injection molded part is made into the second color, the controller of the injection molding machine will send a signal of the core pulling system, rotate the first core of the mold to the second position of the core, and then perform the injection of the second color.

Read More -

Plastic kitchen vegetable and fruit storage trolley mould

6.Four-corner 360-degree plastic storage pulley movement design: The durable kitchen storage pulley wheel has a good mechanical labor-saving design, which can easily move the shelf. Balanced and stable sliding to any place you want, plastic storage trolley wheels can be competent whether it is wooden floor, tiled floor, concrete floor, etc .... without harming the floor surface.

Read More -

PVC 2-Color Band of Slipper injection molud

We only need to have a mold for two-color PVC strap for flip-flops and one 280T two-color injection molding machine. Focare Mold can provide you maximum 16 + 16 cavity two-color strap mold, if you are interested in making two-color PVC strap for flip-flops, please contact us.

Read More -

Thickening Gorgeous Diamond Low-Back Armchair Mold

What are the benefits of plastic furniture? 1. Plastic furniture is often more affordable than other options including wood and metal. 2. Plastic furniture is lightweight and easy to move around and rearrange. 3. Plastic furniture is mostly unbreakable; it won’t be damage with dropping. 4. Wooden furniture can develop cracks and require refinishing 5. Plastic furniture is available for variety of colors. 6. Plastic furniture is waterproof; it is the best option in rain. Plastic won’t be rust or cracked.

Read More -

Foldable stool plastic injection mold

The plastic foldable stool is composed of the stool surface and the stool legs. The connection between the stool surface and the stool legs is hinged. The lower part of the stool surface is concave, the lower part of the two stool legs is M-shaped or similar to M-shaped, and the concave part of the two stool legs and the middle part of the bottom surface of the stool surface are hinged by two connecting rods. The utility model has the advantages that the stool legs can be folded into the stool surface and viewed from the outside, which is only a stool surface and is very convenient to carry. In addition, the utility model has the advantages of reasonable structure, good mechanical properties and low price.

Read More -

Two- color airtight food container plastic injection mold

For this type of airtight food container, there are buckles on the side to ensure the tightness and prevent the leakage. Some buckles are made separately, however we made the two-color lid and buckles as one-piece. Therefore, a two-color lid and a body are one complete set, which makes product be lighter and simple. The weight of lid is 33g (25.5g for PP, 7.5g for TPE), and the body is 34g (33.3g for PP, 0.7g for TPE). On the other hand, producers can avoid on purchasing mould for buckles, which can save time and cost.

Read More -

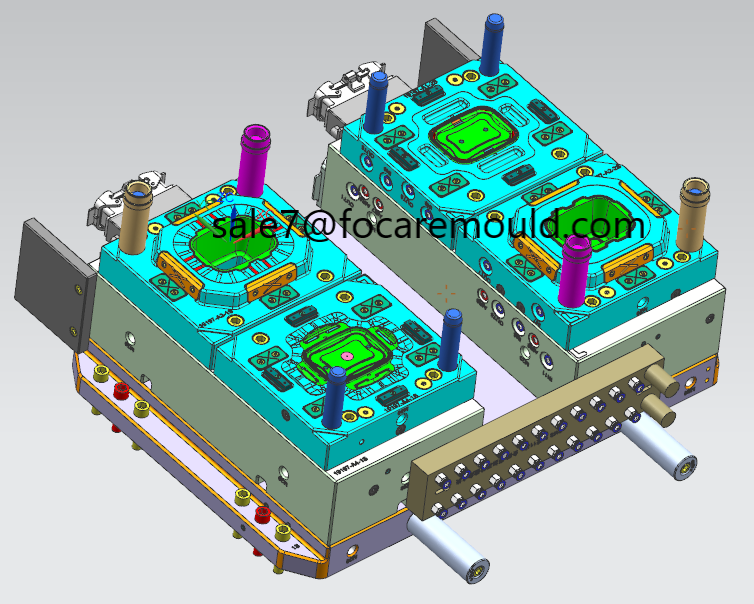

Refrigerator drawer plastic injection mold

Refrigerator drawer belongs to large-scale production plastic mold and requires high standard, so single cavity injection molding process and point gate hot runner are used in injection molding. For the parting surface of the drawer, it determines the structural form of the whole mold, so this design adopts the injection mode of the double parting surface to achieve the stability of the whole refrigerator drawer structure.

Read More