Spray caps of Insecticide Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

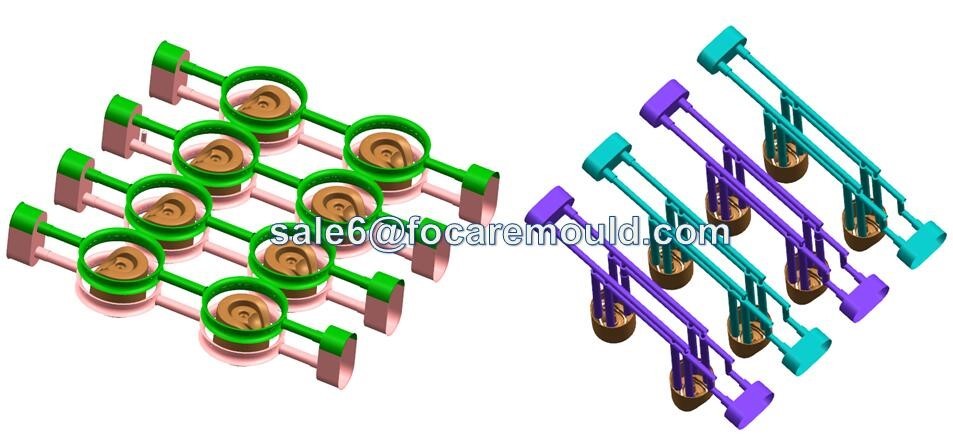

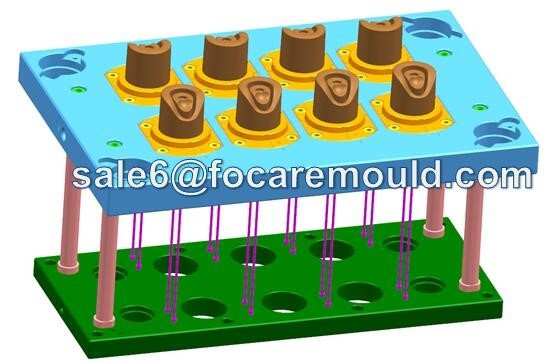

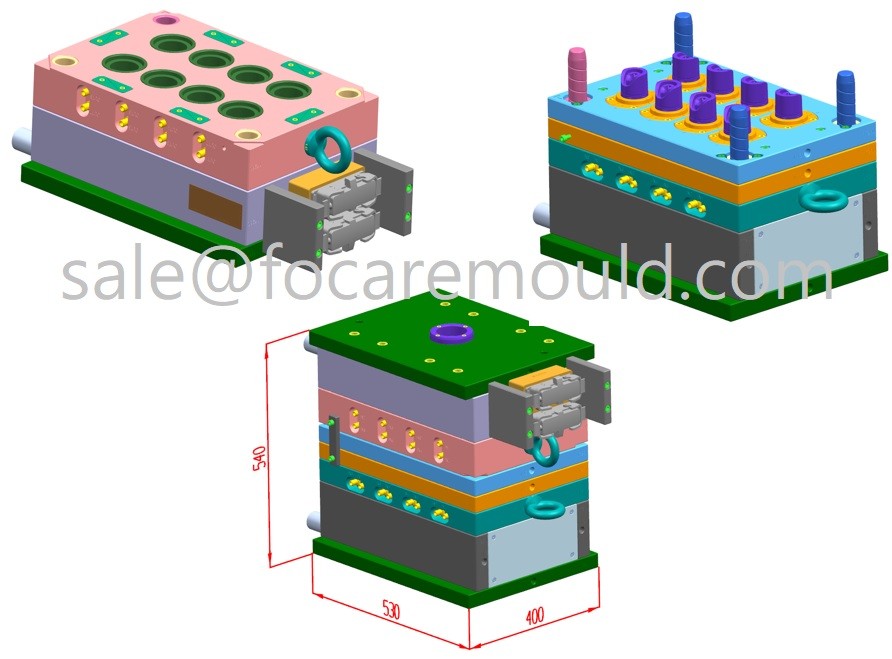

Spray cap molds are used in the molds for producing insecticide shells. They are made in accordance with the shape of the insecticide cover required. They are injection molded with plastic and processed into insecticide shell parts through various processes. The principle of the spray tank is that the liquid is pressed out of the valve by using air pressure. The liquid can be sprayed evenly. The direction and dose can be controlled. Any content can be easily put in and easy to use.

The world's climate is changing but the climate's changes is bringing with it new battles to be fought with the insect population. Whether flying or crawling insects, every country has its own ecology problem.

Modern environmental requirements and lightweight trends have made plastics increasingly replace metal parts in industrial products. Plastic products account for a large part of people's daily necessities. In addition to daily necessities, plastic products are mostly used in the field of cleaning products.

Spray cap molds are used in the molds for producing insecticide shells. They are made in accordance with the shape of the insecticide cover required. They are injection molded with plastic and processed into insecticide shell parts through various processes. The principle of the spray tank is that the liquid is pressed out of the valve by using air pressure. The liquid can be sprayed evenly. The direction and dose can be controlled. Any content can be easily put in and easy to use.

The spray cap has the functions of keeping the product closed, anti-theft opening and safety, so it is widely used in the bottled products. Therefore, the bottle cap is the upstream industry of food, beverage, wine, chemical industry and pharmaceutical industry, and is the key product of bottle and pot container packaging.

Focare Mold has a very professional field in the production of plastic caps. We are not only able to establish a solid foothold in the field of making single-color caps, but also one of the top plastic mold makers in the field of two-color caps. Our mold quality requirements are very rigorous. We have our own set of standards for making molds, because this set of mold quality self-required standards is sufficient for customers to cooperate with our company and fully gain customer trust. From product design to mold design, processing and testing molds, we have sufficient personnel and equipment.