- Home

- >

- Products

- >

- Industrial Parts Mold

- >

- Plastic Portable Tool Box Injection Mould

Plastic Portable Tool Box Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 molds per year

1. PP engineering plastic, good bearing capacity, beautiful appearance, strong plasticity, various colors, large internal volume of portable toolbox.

2. The worktable adopts unique injection molding, with higher strength and smooth surface treatment, it is easy to wipe oil stains. The injection panel can bear the bench vice operation

3. Abundant tool modules can be stored in the drawer of toolbox

4. Sliding guide rail design is adopted on both sides of drawer, which has excellent smoothness and improves service life. The extended distance enables the drawers to be fully opened, making it easy to extract the objects inside the drawers.

5. Each drawer has self-locking function

6. It is suitable in size and can be stored in the trunk of the car. It is convenient. Toolbox of different sizes can be built in together.

Plastic portable tool Box is a compact and light weight tool box with a durable polypropylene construction. It is perfect for the home handy man, to store and carry tools around for maintenance and repair jobs or when working on projects. It features a lift out carry tray for convenience and to maximize space, built in compartments to store smaller items including screws, nuts, bolts, washers, hooks and drill bits and a handle for easy portability.

1. PP engineering plastic, good bearing capacity, beautiful appearance, strong plasticity, various colors, large internal volume of portable toolbox.

2. The worktable adopts unique injection molding, with higher strength and smooth surface treatment, it is easy to wipe oil stains. The injection panel can bear the bench vice operation

3. Abundant tool modules can be stored in the drawer of toolbox

4. Sliding guide rail design is adopted on both sides of drawer, which has excellent smoothness and improves service life. The extended distance enables the drawers to be fully opened, making it easy to extract the objects inside the drawers.

5. Each drawer has self-locking function

6. It is suitable in size and can be stored in the trunk of the car. It is convenient. Toolbox of different sizes can be built in together.

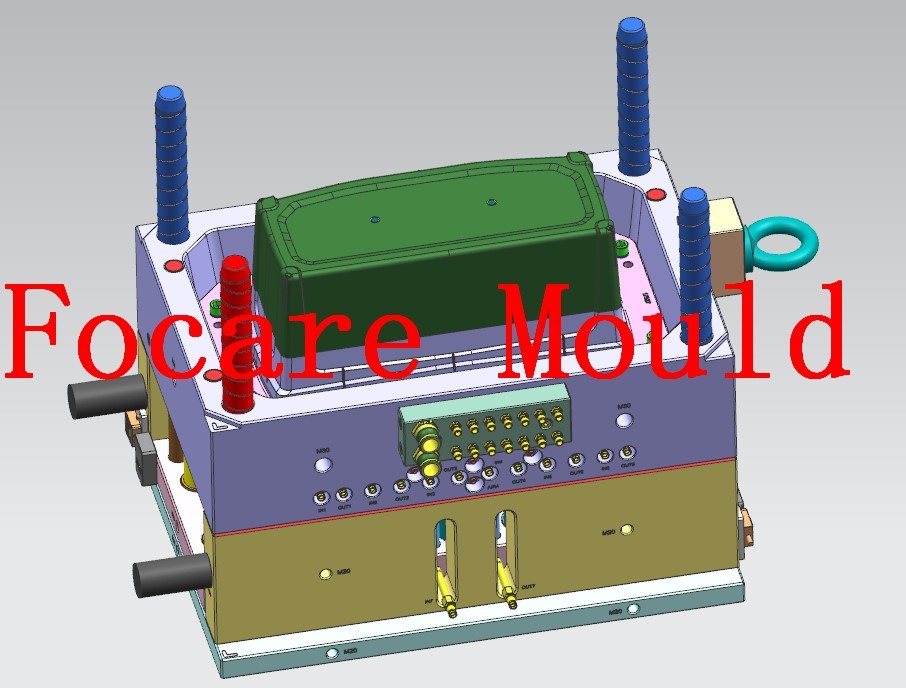

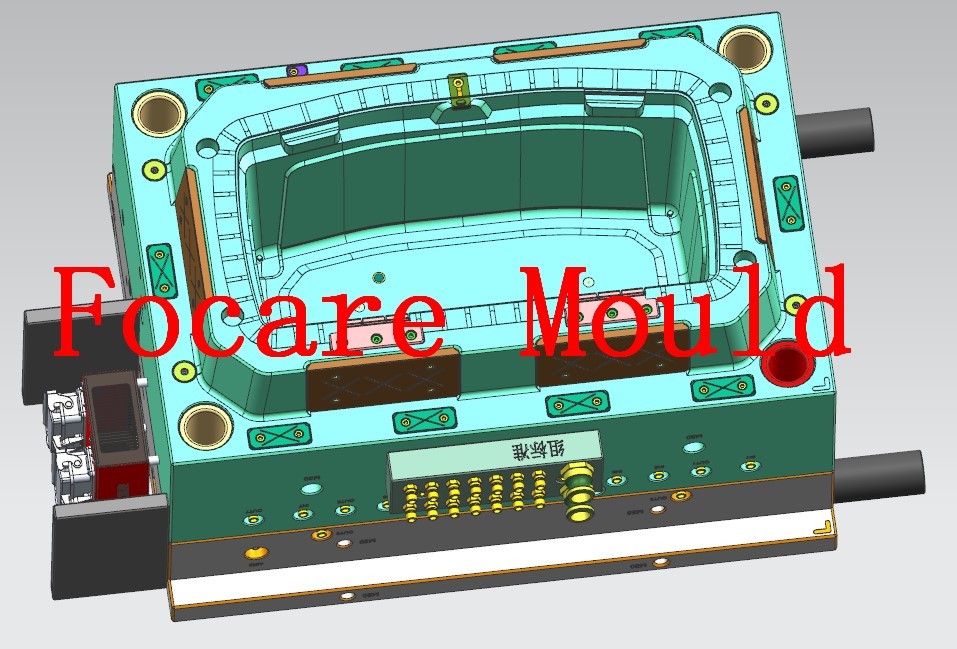

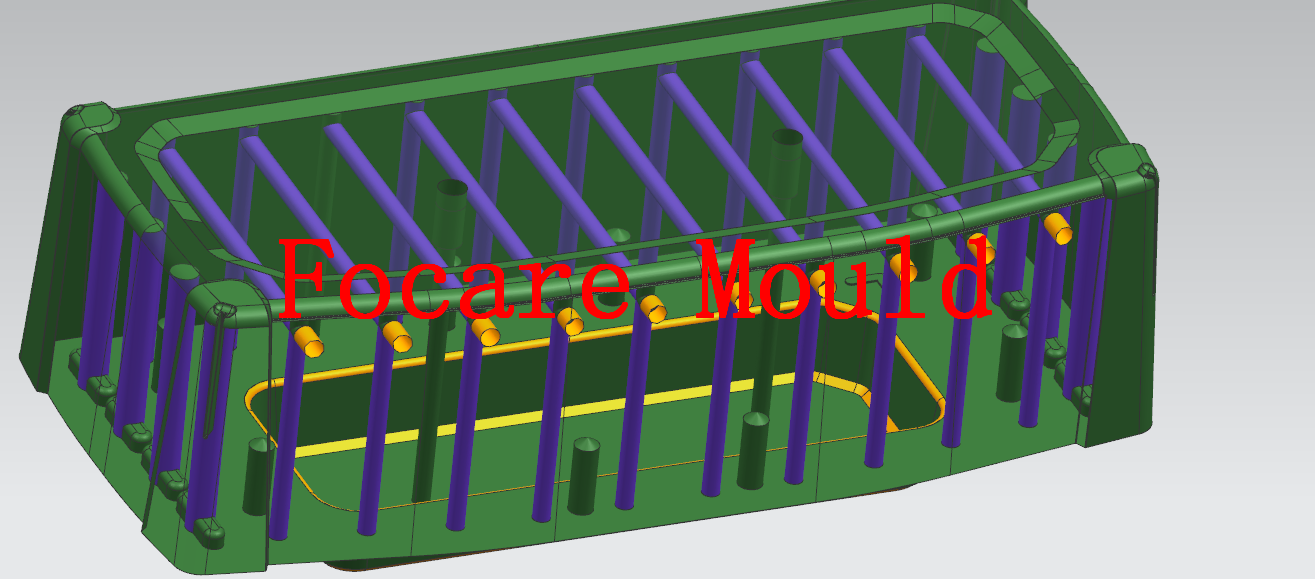

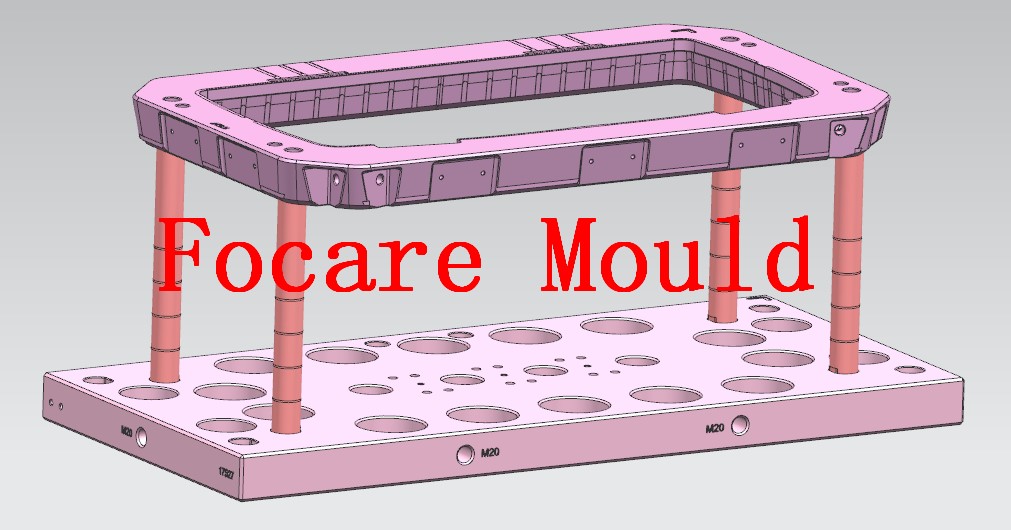

The plastic portable tool box is composed by tool box body, cover, handle, compact box, organized interlayer, lock. The features of mold design are as below:

1. The conventional 2-plate die structure is adopted, and the core part is designed with insert, which is convenient for processing and polishing.

2. Hot runner system, standard water manifold, and all water connections are on the non-operation side.

3. Ejecting system designed with stripper plate for even ejection.

4. The core cooling adopts the dense water channel arrangement, which is very important to provide mold production efficiency and improve product shrinkage deformation.

5. Mold cores and cavities are used H13 steel to enhance the service life of the mold.