- Home

- >

- Products

- >

- Electrical Parts Mold

- >

- Plastic Electrical Junction Box Injection Mould

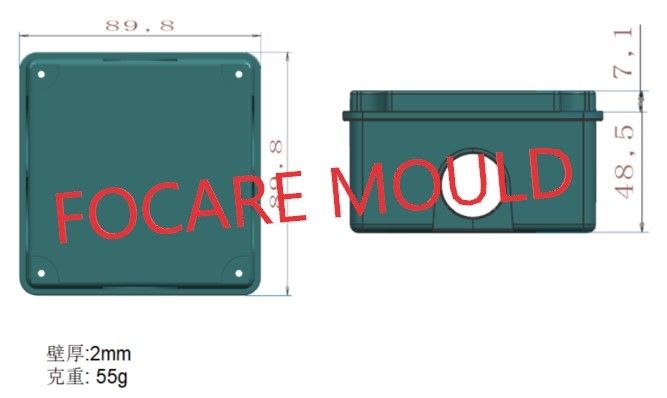

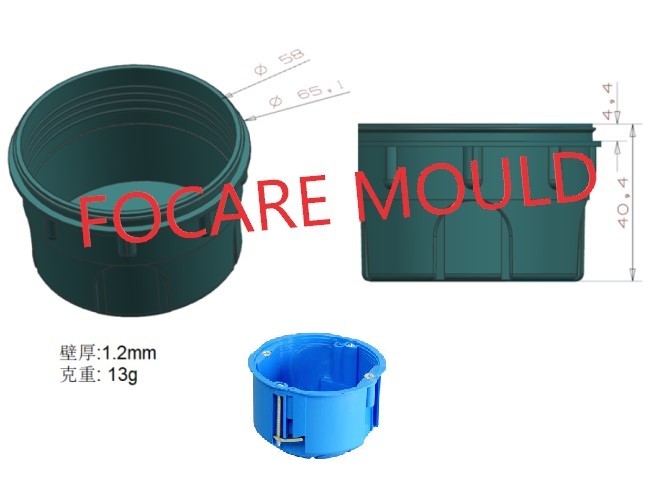

Plastic Electrical Junction Box Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

ABS Plastic Dustproof Waterproof Junction Box Universal Electrical Project Enclosure White 11.8" x 9.8" x 4.7"(300mmx250mmx120mm)

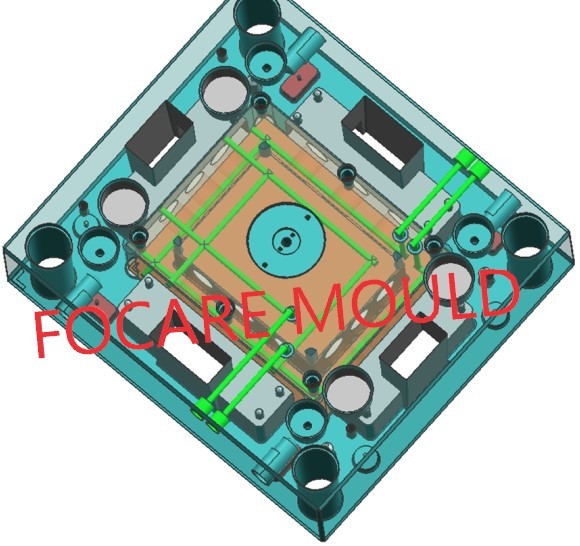

The features of mold design are as below:

1. There are perforations on the 4 sides of the product; therefore, the cavity needs a small mold opening.

2. The 4 sides of the I-shaped drive the 4 sides of the slider to pull the core.

3. For the mold of the cover, in order to make the product look beautiful, the anti-adhesive is designed so that the product is firmly on the side of the fixed mold.

4. Simple mold design for easy maintain

5. On the side of the core, insert the insert inside and eject it with a thimble.

1. The box body and the cover are fixed by four plastic screws which are not easy to fall off

2. The product contains EMI radiation, anti-static material, in order to protect the collection, protection of electrical and electronic equipment

3. Through the mounting hole at the bottom of the box body can be directly fixed on the wall surface

4. According to customer needs to open holes, with waterproof connector

Nice large box for an outdoor electronics project (Arduino controlled relays) that had to be kept dry. This is actually more of a junction box without any internal hardware, which was just what I needed so I could use water proof electrical connectors. It was large enough that I could fit a metal project box inside it to isolate the 110v supplies and relays, to avoid transmitting electrical noise to the Arduino (probably overkill but I don’t want to have to chase down intermittent problems). Would buy it again!

Good design, solid construction. I used it to protect a cable splitter that my TV company installed outside the house, fully exposed to the weather, now it's not only looking much neater, but I won't see it rusting anymore.

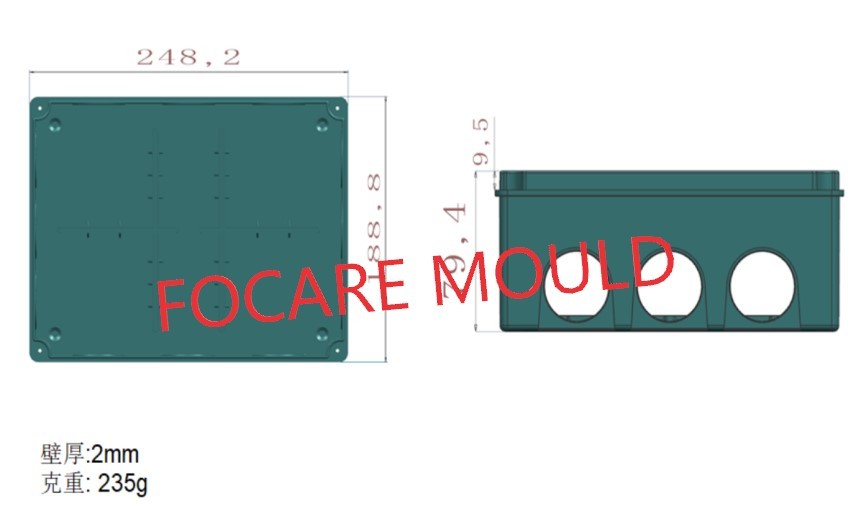

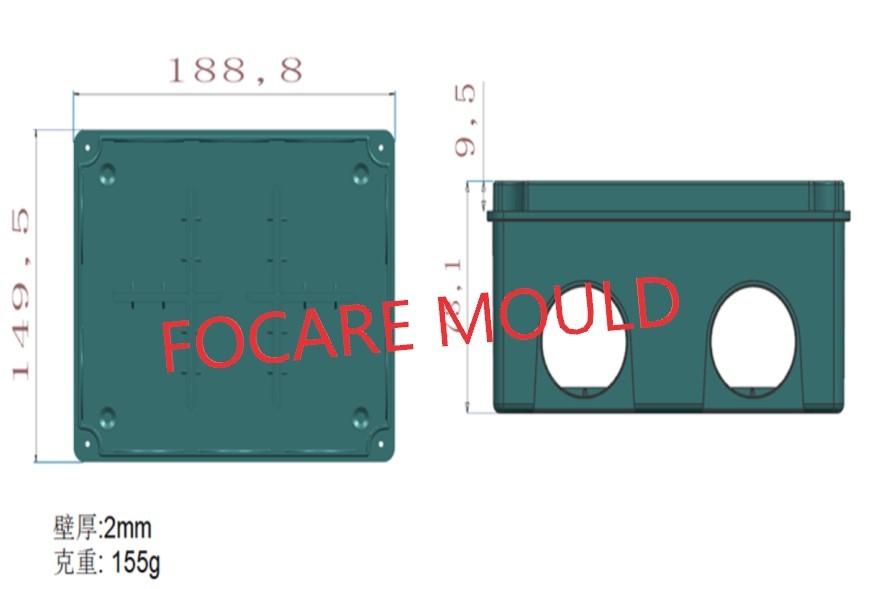

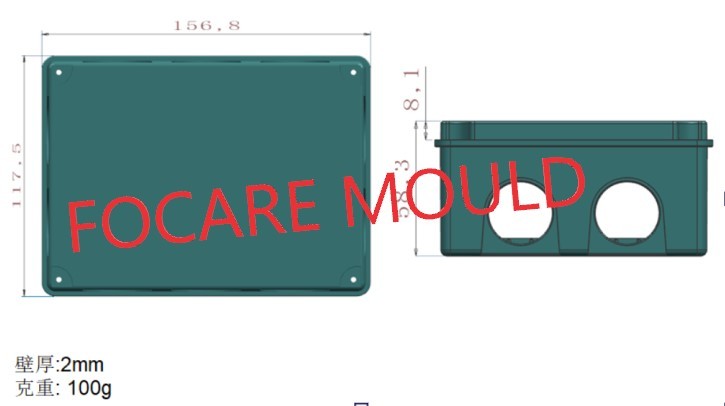

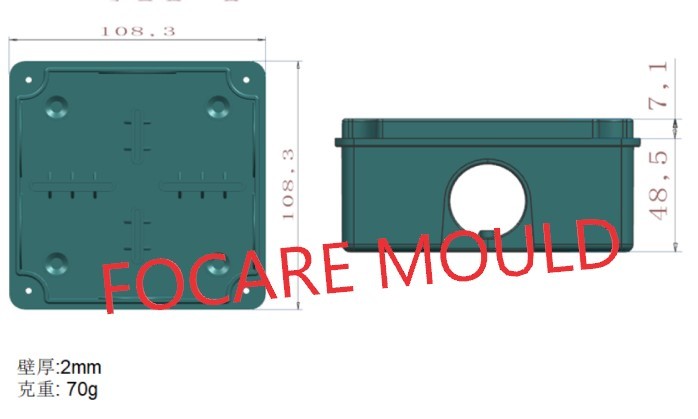

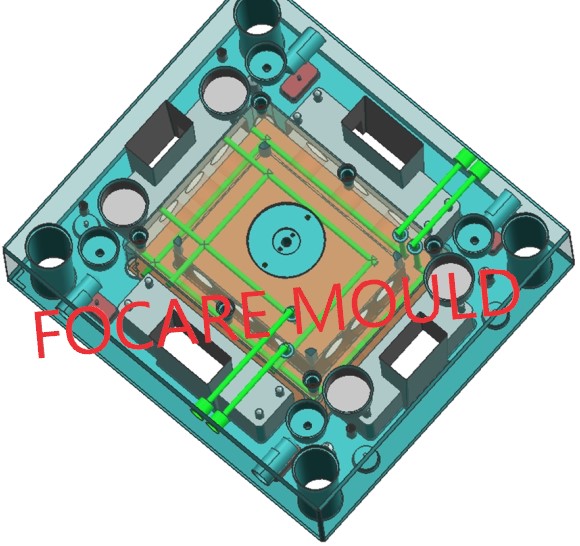

The features of mold design:

1. There are perforations on the 4 sides of the product; therefore, the cavity needs a small mold opening.

2. The 4 sides of the I-shaped drive the 4 sides of the slider to pull the core.

3. For the mold of the cover, in order to make the product look beautiful, the anti-adhesive is designed so that the product is firmly on the side of the fixed mold.

4. Simple mold design for easy maintain

5. On the side of the core, insert the insert inside and eject it with a thimble.