- Home

- >

- Products

- >

- Household Mold

- >

- Plastic Modular Bevel Storage Box Injection Mould

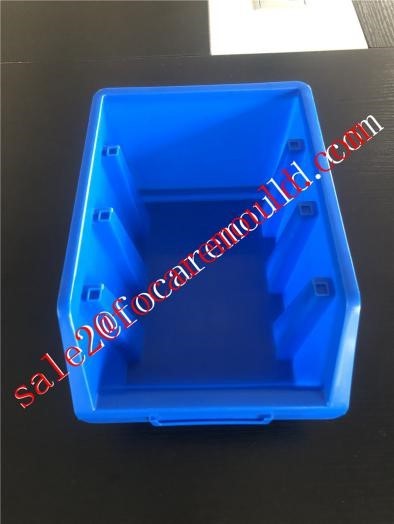

Plastic Modular Bevel Storage Box Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

This modular bevel storage box has the characteristics of folding resistance, anti-aging, high loading strength, stretching, compression, tearing, high temperature, rich color, lightness, durability and stacking. We can make molds for all kinds of specifications and sizes according to the user's requirements, which can be capped, dust proof and beautiful in appearance.

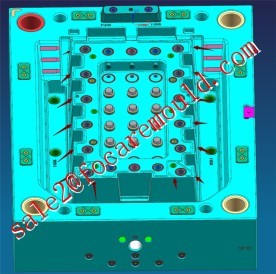

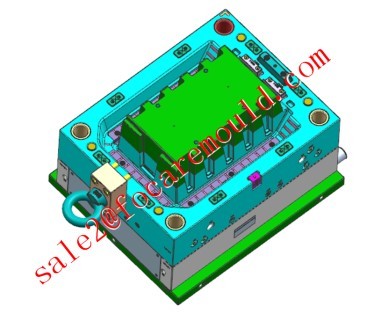

The features of mold design are as below:

1. The cavity is made with insert part which is to process and maintenance in future.

2. Stripper plate for balancing ejection.

3. The protruding part of plastic box is used as the insert, which can release and exhaust the air, making it easier to eject the product.

4. High efficient cooling circular design for shortening cycle time.

5. Excellent NC processing to increase the assembly precise of mold to reduce flash.

Plastic modular bevel storage is also called Multipurpose Modular Storage Box, Storage Bins & Boxes or tool box. It is mainly made of HDPE or PP, which is suitable for the storage and various small parts, tools, materials and stationery in factories and offices. It is widely used in machinery, automobile, home appliances, light industry, electronics and other industries. It is acid and alkali resistant, oil resistant, non-toxic and tasteless. It also can be used to hold food. It is easy to clean, convenient to turn parts, orderly to stack and easy to manage.

This modular bevel storage box has three size, small, middle and large. Three are the characteristics of folding resistance, anti-aging, high loading strength, stretching, compression, tearing, high temperature, rich color, lightness, durability and stacking. We can make molds for all kinds of specifications and sizes according to the user's requirements, which can be capped, dust proof and beautiful in appearance.

The features of mold design are as below:

1. The cavity is made with insert part which is to process and maintenance in future.

2. Stripper plate for balancing ejection.

3. The protruding part of plastic box is used as the insert, which can release and exhaust the air, making it easier to eject the product.

4. High efficient cooling circular design for shortening cycle time.

5. Excellent NC processing to increase the assembly precise of mold to reduce flash.