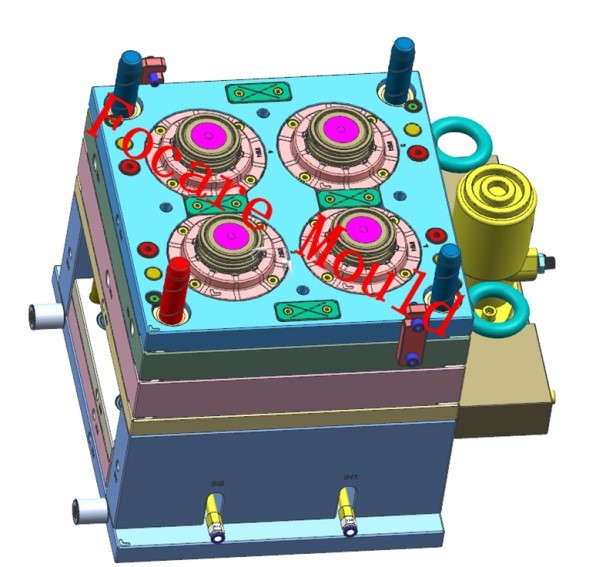

Threaded Cap Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

Cap size: ø90.7 X 93 X 25mm

Cap weight: 36gm

Material: HDPE

Mold: 4 cavities

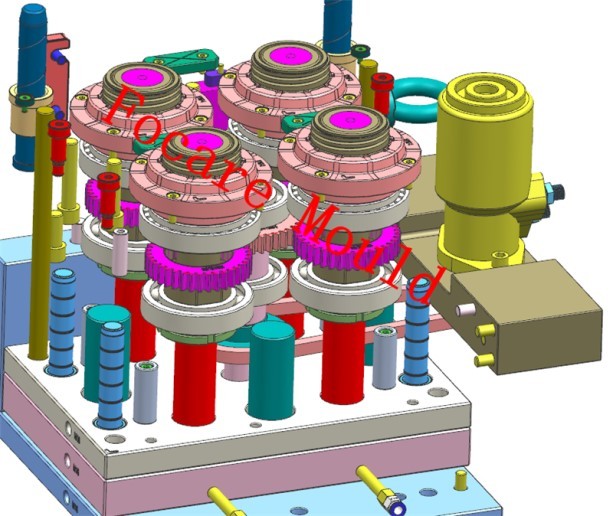

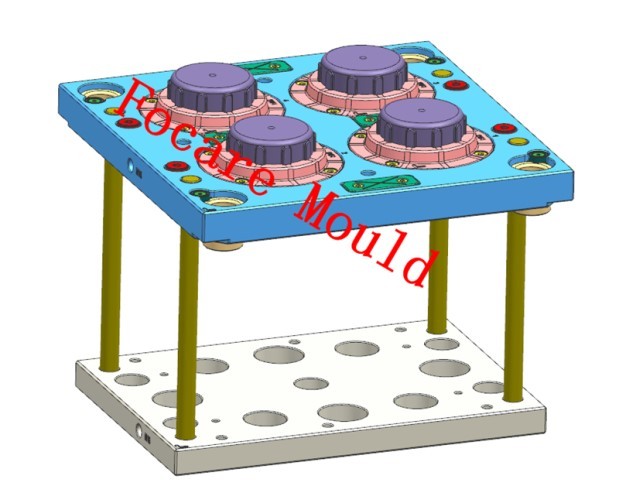

The thread part of this cap is designed with thread rotation off, and the motor device is used to drive the gear to rotate. The cap must be designed with a stop device to prevent the product from following the rotation when the thread rotates, resulting in the scratch of the cap thread. After the thread part of the cap is separated, use the ejector plate to eject. Compared with thread strength and thread rotation, thread rotation is more difficult to make, which requires high-precision processing equipment, high installation accuracy and accurate positioning between plates, otherwise it is easy to cause the problem of parts stuck and motor or oil cylinder not moving.

The cap is an important part of food and beverage packaging, and it is also the place where consumers first contact with products. The bottle cap has the functions of keeping the product closed, anti-theft opening and safety, so it is widely used in the bottled products. Therefore, the bottle cap is the upstream industry of food, beverage, wine, chemical industry and pharmaceutical industry, and is the key product of bottle and pot container packaging. In the early stage of lid development, we used cork, tinplate crown lid and unscrewing lid. Up to now, we have developed aluminum long neck aluminum lid, carbonated aluminum lid, hot filling aluminum lid, injection aluminum lid, medicine lid, open ring lid, safety button claw lid, plastic lid and other products.

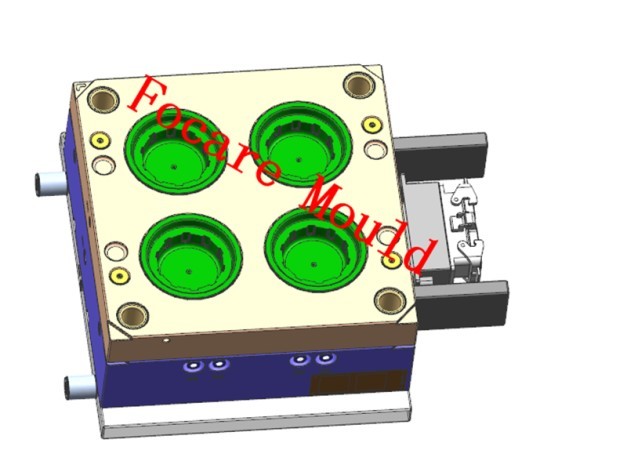

The mold is designed with a separate insert, and each cavity has a separate positioning system, which is convenient to adjust the cap center and ensure that the wall thickness of the cap is uniform and the size is stable after the injection

The thread part of this cap is designed with thread rotation off, and the motor device is used to drive the gear to rotate. The cap must be designed with a stop device to prevent the product from following the rotation when the thread rotates, resulting in the scratch of the cap thread. After the thread part of the cap is separated, use the ejector plate to eject. Compared with thread strength and thread rotation, thread rotation is more difficult to make, which requires high-precision processing equipment, high installation accuracy and accurate positioning between plates, otherwise it is easy to cause the problem of parts stuck and motor or oil cylinder not moving.