- Home

- >

- Products

- >

- Baby Use Mold

- >

- Kids Tricycle Plastic Injection Mould

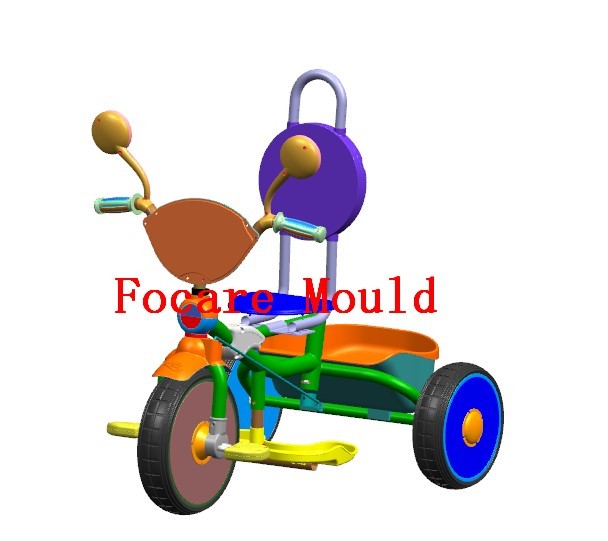

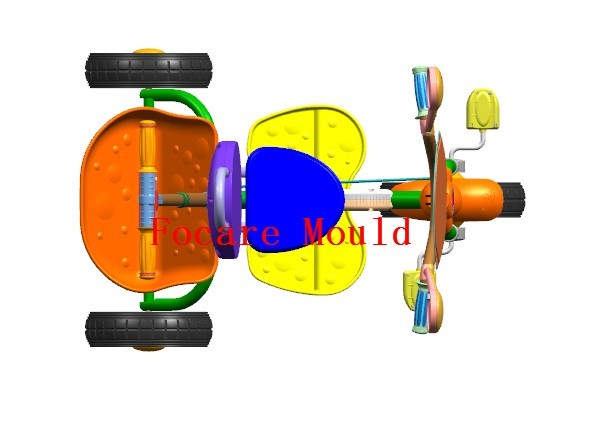

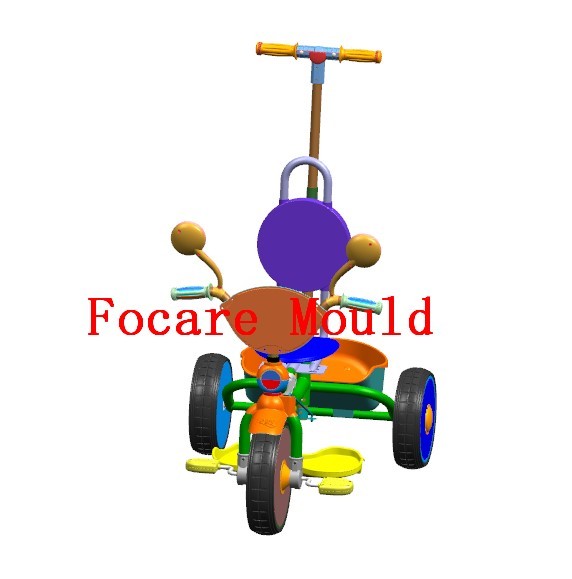

Kids Tricycle Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

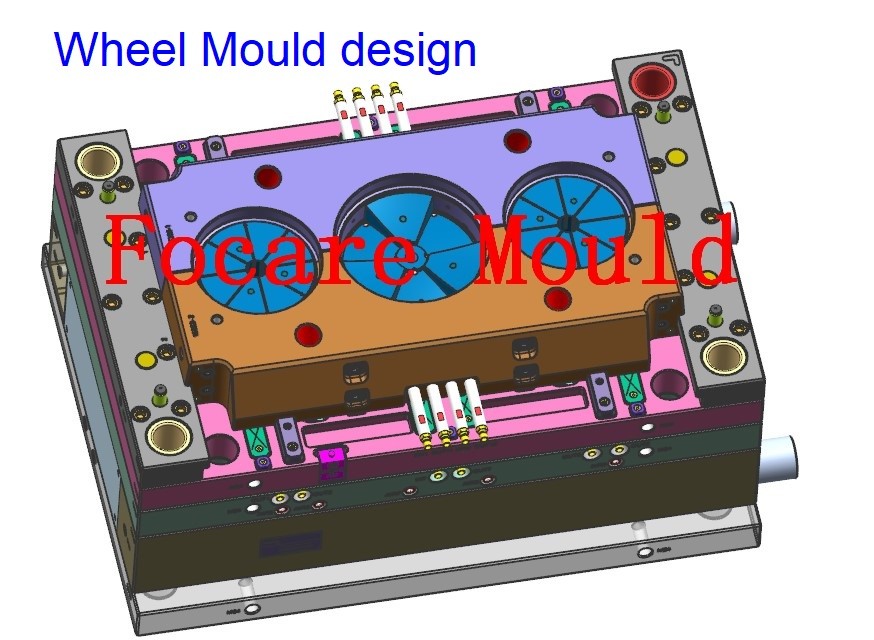

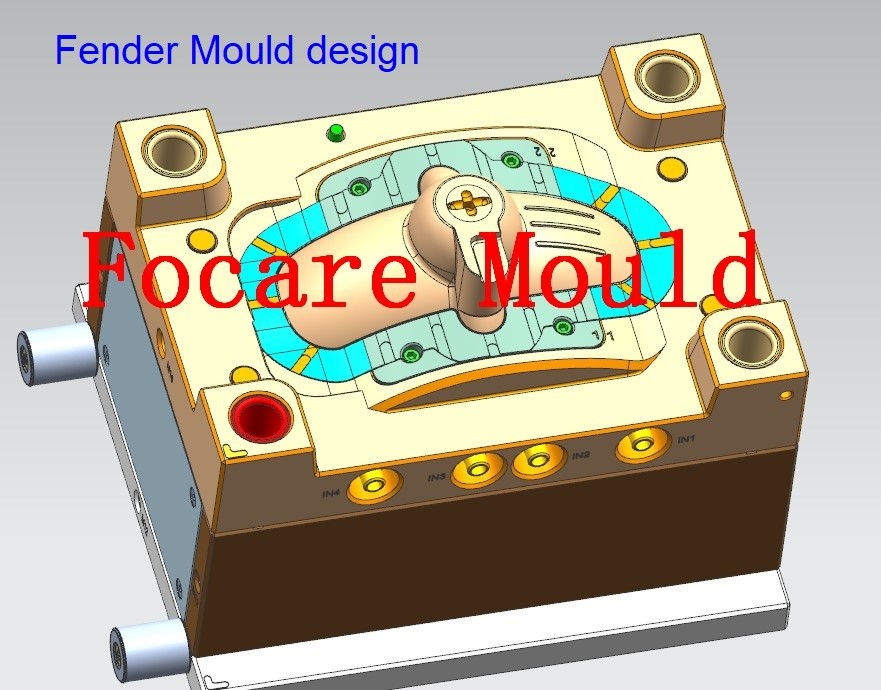

The commonly used children's tricycle mould steels are 45#, 40Cr, P20, 2738, 2316, 718, NAK80, S136, etc. Generally, we suggest to use steel 718 and Shanghai Baosteel P20.

Good mold structure design is the premise of a qualified mold manufacturing. The mold structure and product structure should be analyzed in all aspects, including mold draft angle, miniature of product surface, design of pouring system, design of exhaust system, design of cooling system, etc. The most important and most likely problems of these molds will be repeatedly tried in the mold structure design Proven.

Children's tricycle is a popular toy for preschool children. Pay attention to the following points when purchasing.

1. The content of harmful elements in the surface coating shall meet the safety requirements.

2. There shall be no protrusion in the specified area of children's tricycle. Therefore, there is a kind of tricycle for both pushing and riding in the market. When it is used for children's riding, the push handle must be folded down before it can be used for children's riding.

3. The kid’s tricycle shall not have any pinch points that may be injured, and any movable parts that may be touched, the pores between the two shall be less than 5mm or more than 12mm, so as to prevent children from pinching their fingers.

4. For children under three years old, if there are accessible small parts, the volume of the tricycle should be larger than the diameter of 31.75mm × 51,75mm oblique cutting cylinder, in order to prevent children from accidentally swallowing it or choking it into the trachea, leading to serious consequences such as suffocation.

The commonly used children's tricycle mould steels are 45#, 40Cr, P20, 2738, 2316, 718, NAK80, S136, etc. Generally, we suggest to use steel 718 and Shanghai Baosteel P20.

Good mold structure design is the premise of a qualified mold manufacturing. The mold structure and product structure should be analyzed in all aspects, including mold draft angle, miniature of product surface, design of pouring system, design of exhaust system, design of cooling system, etc. The most important and most likely problems of these molds will be repeatedly tried in the mold structure design Proven.

Focare Mould company with more than 15 years of mold making experience, we can provide one-stop services from product design to mold design to mold making, We use high-quality steel, high-precision CNC processing, reasonable mold structure design, and strive to provide customers with high cost-effective mold and services.