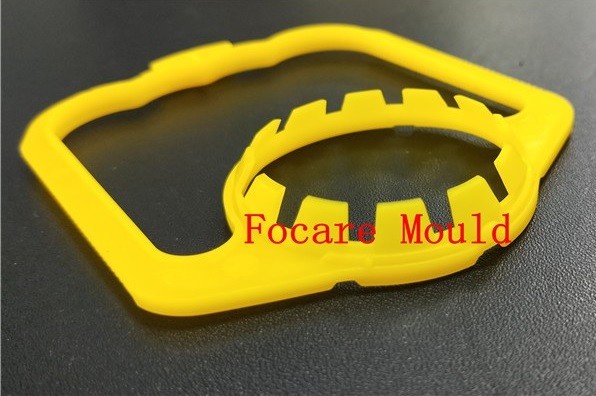

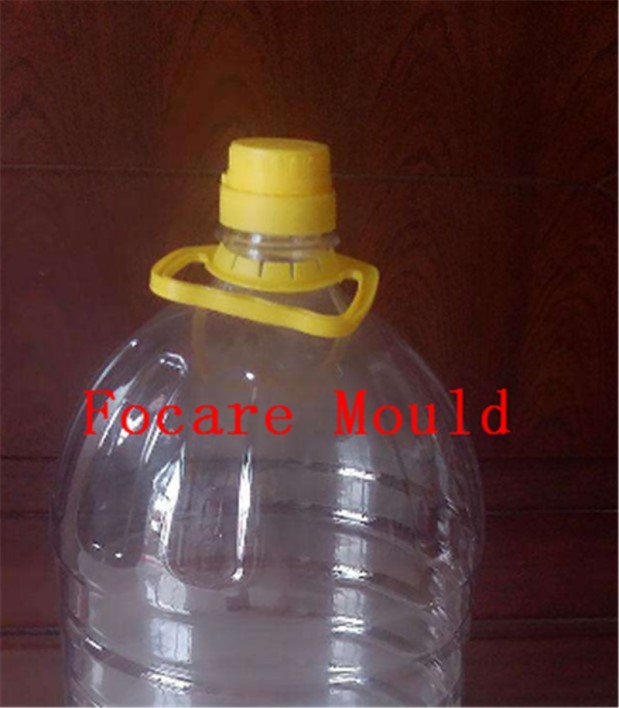

PET Bottle Handle Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

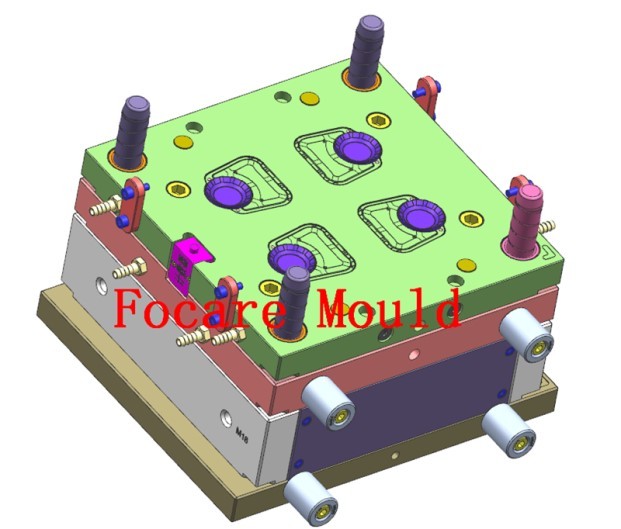

Design and manufacturing of handle mould---

1. Mold design of handle mold with 4 ~ 32 cavities.

2. Steel of mold cores and cavities is stainless steel with heat treatment.

3. Design of interchangeable die components for easy maintenance.

4. Specially designed nozzle and fast color changing hot runner system according to customer’s requirement.

5. All molds parts are machinery with CNC equipment.

Handle of PET bottle is to help users to carry the PET bottle easily. A qualified handle is not only strong enough to carry the bottle, no broken and no loose during carry, but also good design for auto assembly lines of handle applicator.

Design and manufacturing of handle mould---

1. Mold design of handle mold with 4 ~ 32 cavities.

2. Steel of mold cores and cavities is stainless steel with heat treatment.

3. Design of interchangeable die components for easy maintenance.

4. Specially designed nozzle and fast color changing hot runner system according to customer’s requirement.

5. All molds parts are machinery with CNC equipment.

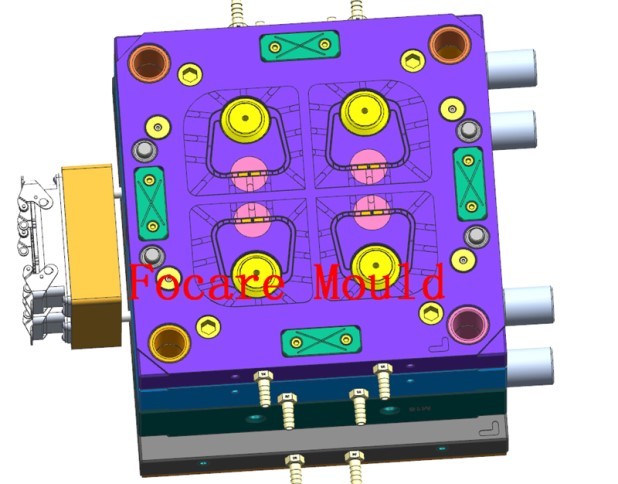

Hot runner system---

The handle injection mold adopts a hot runner system with superior thermal conductivity. The heat conduction is fast, and the handle can be heated rapidly in the manufacturing process to achieve the ideal heating effect. There is a micro nozzle in each cavity of the hot runner handle injection mold, which ensures a large injection flow, a small handle connection point and good thermal conductivity.

Optional faster color changing hot runner system---

At the same time, we provide a fast color change hot runner system, which is convenient for making various color handles, reducing material waste and cost saving.

Mold steel and processing tools---

The handle injection mold is made of superior steel. In order to meet different processing requirements, we will choose different mold steel to make core, cavity, and guide post, frame and so on. High hardness and good process ability are the advantages of the above steels. CNC machining center, high-precision coordinate boring machine and high-pressure EDM molding machine ensure accurate processing and high-quality finished products. The main characteristics of these equipments are accurate and fast processing.