Plastic Tea Bottle Cap Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

The general water bottles are round and sometimes take space in the bags, but these water bottles are square. If they are placed properly, they can save a lot of space inside your bag.

Due to increased environmental awareness, more and more people will carry water bottles with them when they go out. In this way, we not only do our best for the environment, but also reduce our chances of drinking sugary drinks.

The general water bottles are round and sometimes take space in the bags, but these water bottles are square. If they are placed properly, they can save a lot of space inside your bag.

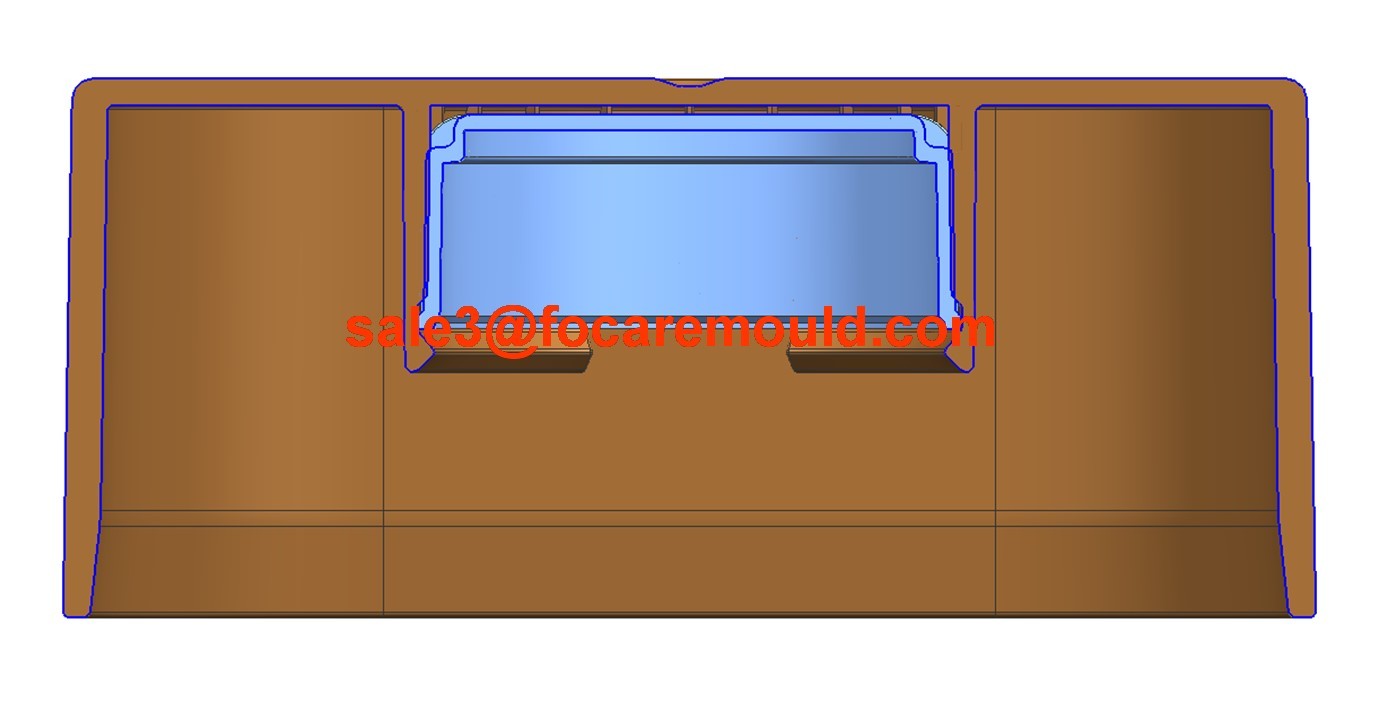

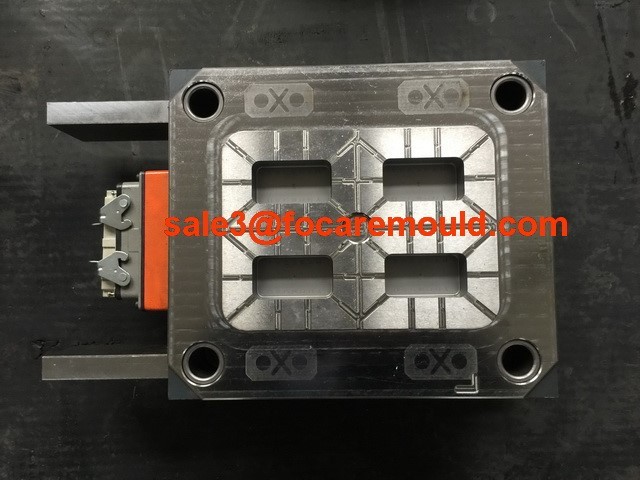

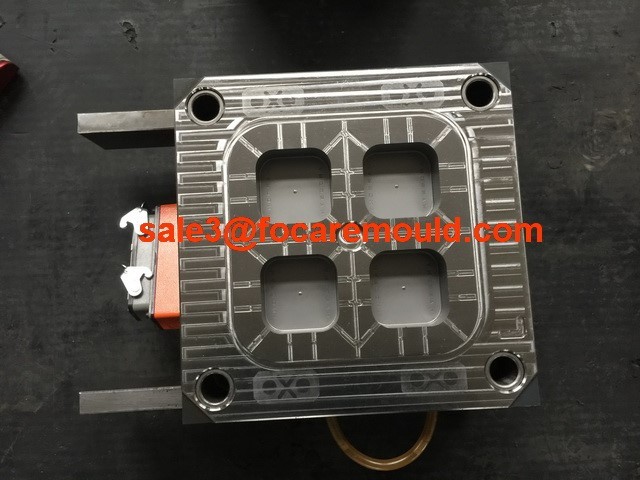

Since these two water bottle caps are the parts that consumers can directly touch with their hands and watch with their eyes, the customer has high requirements for the appearance of bottle caps at the beginning.

1. The texture of these plastic caps should be very fine with touching.

2. Inside the outer caps, there is a place for the inner cap which has the function of seal the bottle well and avoid the leakage of water. When the consumers open the outer caps, the inner cap should be opened in the same time, it means whether the water bottle cap is opened or closed, the inner cap and the outer cap must be tightly combined.

3. According to the regulations of Dubai, no glue can be used for the inner and outer cap. We can only make special structure for the outer cap to let the inner and outer cap can be tightly combined.

4. When doing the tightness test, we have to fill the water bottle with water, and then just grab the outer periphery of the outer cap, shake the whole water bottle desperately, and shake it at all angles. This test will pass only the outer and inner caps cannot be separated after shaking.

5. As there is a structure for placing the inner cap inside the outer cap, it is really easy to have shrinkage mark on the top of the outer cap. Through our experienced injection molding master, who constantly adjusted the machine parameters, and finally adjusted the shrinkage mark as small as possible.

Although customer has high requirements for the appearance of the products, with the efforts of our experienced team in Focare Mould, we once again perfectly solve all the problems.