- Home

- >

- Products

- >

- Household Mold

- >

- Toilet Seat and Lid Plastic Injection Mould

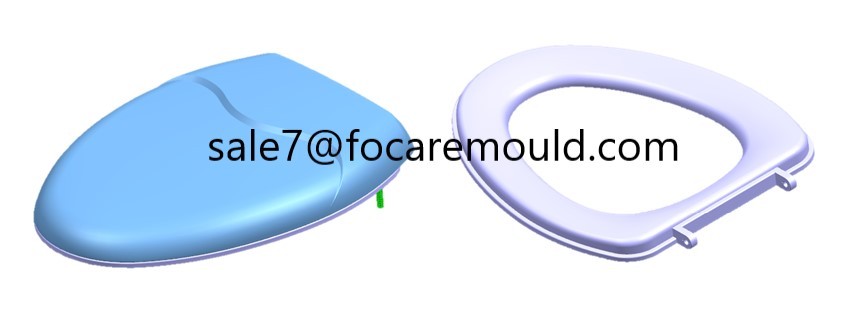

Toilet Seat and Lid Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

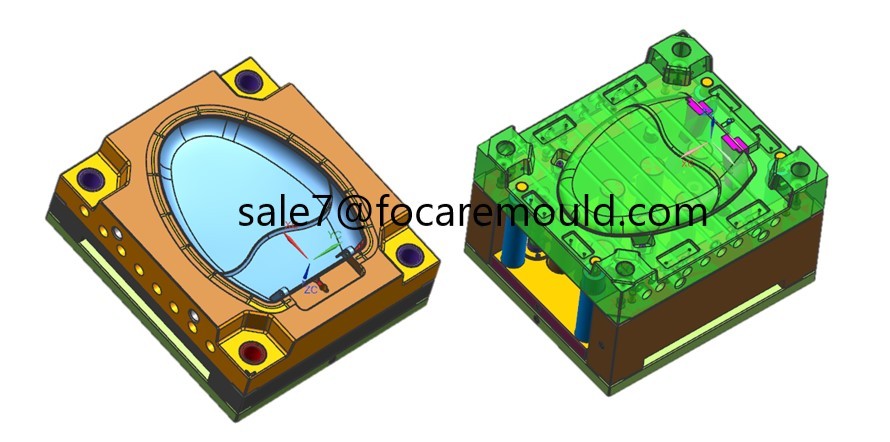

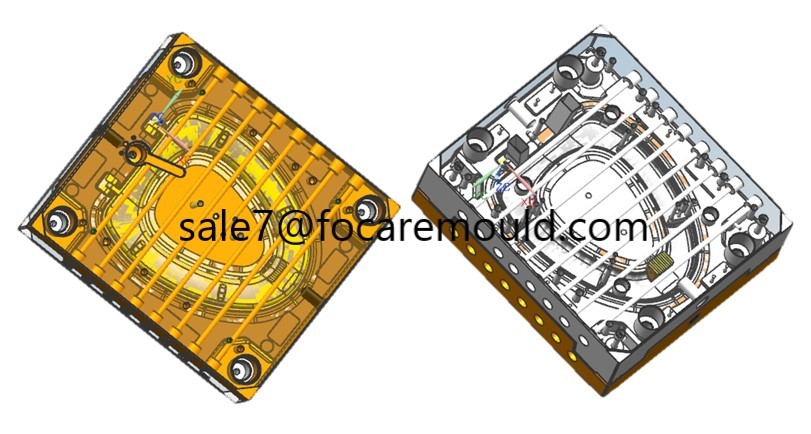

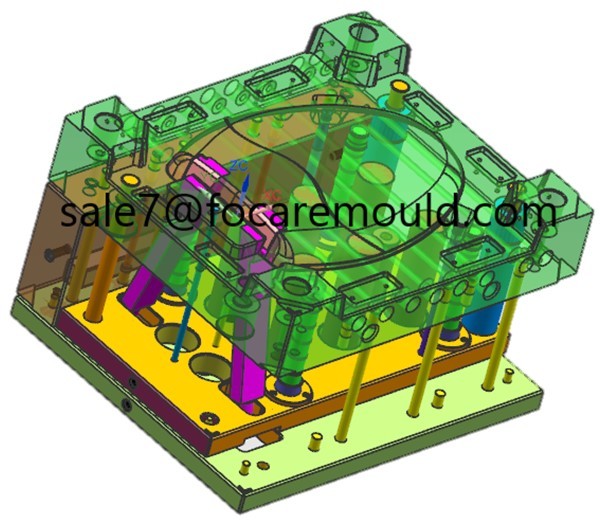

The total weight of the whole set plastic toilet seat is 650 gm, made by PP. The two plastic injection moulds of main body are made 1 cavity with one tip hot runner. As for the rest of the components we apply cold runner and 4 cavities. Seven moulds plus a 125 and 350 ton plastic injection machine is sufficient to manufacture a plastic toilet seat, which is really a good investment while the toilet seat is so high demand on markets.

A toilet seat is a hinged unit consisting of a round or oval open seat, and usually a lid, which is bolted onto the bowl of a toilet used in a sitting position. A toilet seat consists of the seat itself, which may be contoured forum the user to sit on, and the lid, which covers the toilet. Toilet seats are manufactured in a range of different styles and colors, and they may be furnished matching the style of the toilet itself. They are usually built to fit the shape of the toilet bowl

The most important thing to be noticed while making a toilet seat mould is the high demand of product smooth appearance. Therefore, you are suggested to select better steel for the main body, which is much stronger and durable. Plus the precision process and perfect polishing, the product won’t have any flush which may make customers have uncomfortable experience or get scratch during the period of using it. Also the mould use age will be longer.

Besides, a complete set of plastic toilet seat have plenty of components, it needs seven plastic injection moulds to complete one set. We need to think carefully thorough the assembly between all components to make a high-quality and well-functioned plastic toilet seat.

The total weight of the whole set plastic toilet seat is 650g, made by PP. The two plastic injection moulds of main body are made 1 cavity with one tip hot runner. As for the rest of the components we apply cold runner and 4 cavities. Seven moulds plus a 125 and 350 ton plastic injection machine is sufficient to manufacture a plastic toilet seat, which is really a good investment while the toilet seat is so high demand on markets.