-

Two color jar cap flip top lid injection mold

The basic information of two color jar cap flip top lid injection mold: Steel: Germany imported steel DIN1.2344 with hardness 45-48HRC Cavity: 8 Injection: 16-tips hot runner piont gate Suggested Machine: 400T two-color plastic injection machine with rotary table Size: 640X700X729mm, 2160kgs

Read More -

Two color water bottle cap mold

Two-color outdoor water bottle cap mold information Product size:69 X 102 x 44mm Product weight: 35g Mold cavity:2+2 cavity Mold main material:S136 with hardness 48-52HRC Mold injection system:3 tips hot runner gate Mold size:900 X 600 X 500mm Suitable machine:250ton two component injection mold machine

Read More -

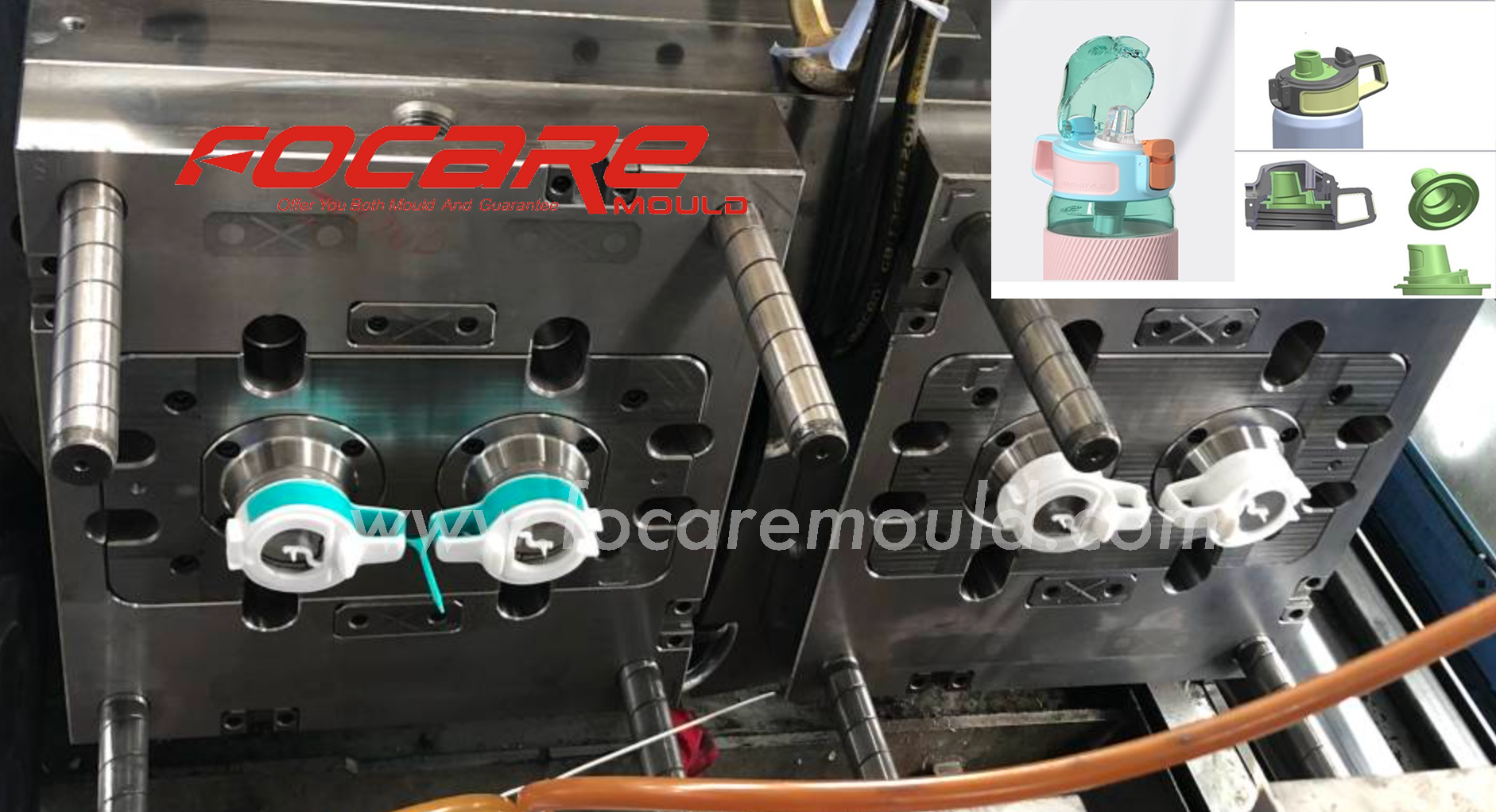

Two-color flip top cap mold with in-mold auto-closing

The details of Two-color flip top cap mold with in-mold auto-closing Material : PP+PP Mold Cavity:8+8 cavity Mold Injection System:1S : 8 tip point hot runner gate / 2S : 8 tip point hot runner gate Mold Size:890 X 530 X 541 mm

Read More -

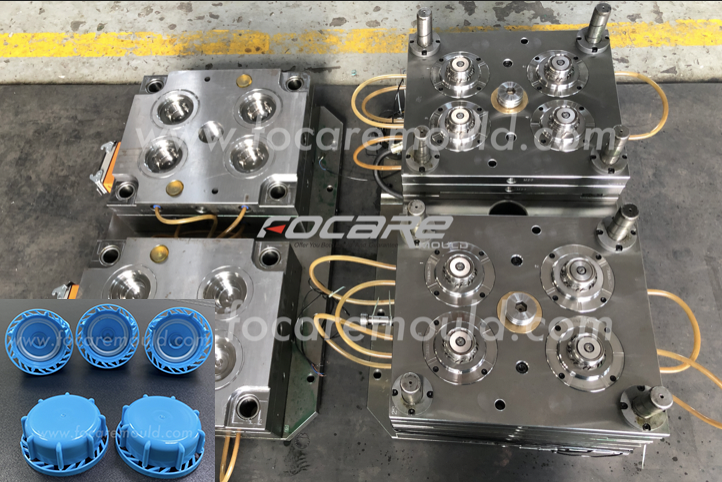

Two color jerry can screw sealing cap injection mold

Product Material:HDPE+rubber Product size: 66 X 25 mm Product weight: 13.7 g Mold Cavity:4+4 cavity Mold Main Material:2344 Mold Injection System:8 tip point hot runner gate Mold Size:890 X 600 X 506 mm Suitable injection molding machine:280ton two color injection molding machine

Read More -

Flip-top cap plastic injection mold

Flip-top caps are necessities of life. They are most common seen to package lotion, or shampoo. Flip-top caps should be light and delicate, with good sealing affect to prevent water leakage, no tips or burrs to scratch customers, with good assembling affect with bottle, and the most difficult part, the connection of top and base should have great flexibility to ensure the smoothness of cap action.

Read More -

PET Bottle Handle Plastic Injection Mould

Design and manufacturing of handle mould--- 1. Mold design of handle mold with 4 ~ 32 cavities. 2. Steel of mold cores and cavities is stainless steel with heat treatment. 3. Design of interchangeable die components for easy maintenance. 4. Specially designed nozzle and fast color changing hot runner system according to customer’s requirement. 5. All molds parts are machinery with CNC equipment.

Read More -

Plastic Tea Bottle Cap Injection Mould

The general water bottles are round and sometimes take space in the bags, but these water bottles are square. If they are placed properly, they can save a lot of space inside your bag.

Read More -

Spray caps of Insecticide Plastic Injection Mould

Spray cap molds are used in the molds for producing insecticide shells. They are made in accordance with the shape of the insecticide cover required. They are injection molded with plastic and processed into insecticide shell parts through various processes. The principle of the spray tank is that the liquid is pressed out of the valve by using air pressure. The liquid can be sprayed evenly. The direction and dose can be controlled. Any content can be easily put in and easy to use.

Read More -

Plastic Flip Top Lotion Caps Injection Mould

Most of the plastic flip top caps mould are designed with two-time ejection structure. The core is pushed out two times. The stripper plate and the ejector sleeve in the middle of the product are pushed out together to 14mm, and then the stripper plate push out continually until the flip top caps drops.

Read More