- Home

- >

- Products

- >

- Caps Mold

- >

- Flip-Top Caps Mold

- >

- Flip-top cap plastic injection mold

Flip-top cap plastic injection mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Flip-top caps are necessities of life. They are most common seen to package lotion, or shampoo.

Flip-top caps should be light and delicate, with good sealing affect to prevent water leakage, no tips or burrs to scratch customers, with good assembling affect with bottle, and the most difficult part, the connection of top and base should have great flexibility to ensure the smoothness of cap action.

Flip-top caps are necessities of life. They are most common seen to package lotion, or shampoo.

Flip-top caps should be light and delicate, with good sealing affect to prevent water leakage, no tips or burrs to scratch customers, with good assembling affect with bottle, and the most difficult part, the connection of top and base should have great flexibility to ensure the smoothness of cap action.

To guarantee every detail is well taken care of, Focare Mould, we will focus on:

1. Mold precision: Molds with high precision is the basic reason to produce high quality products and is also the factor which directly affects the production fluency and mold life.

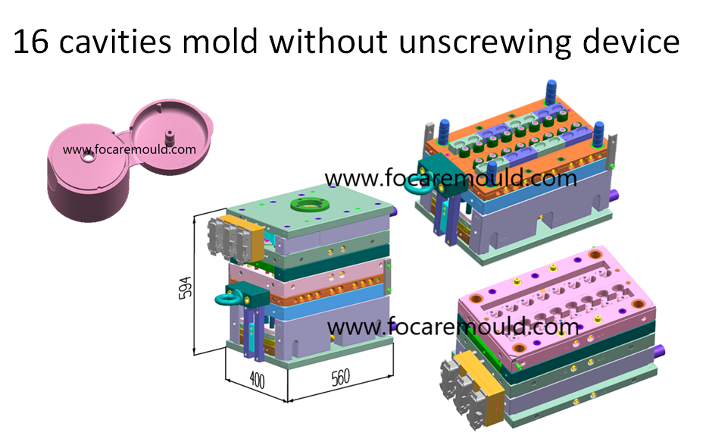

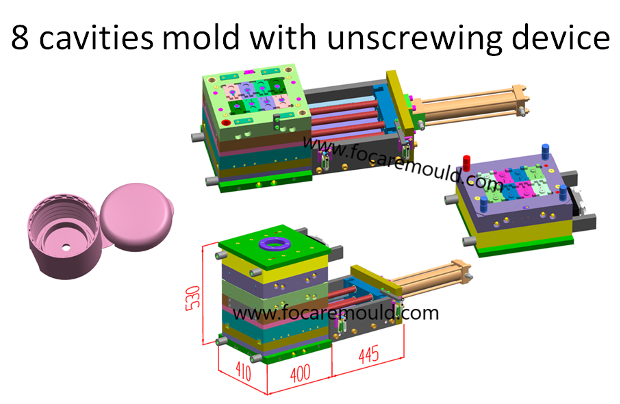

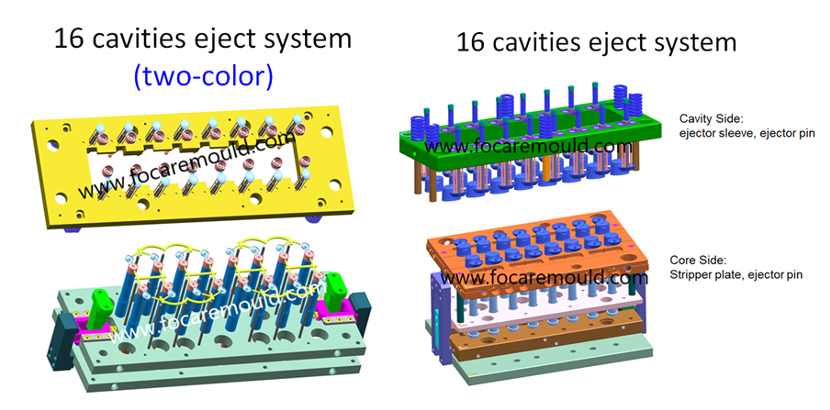

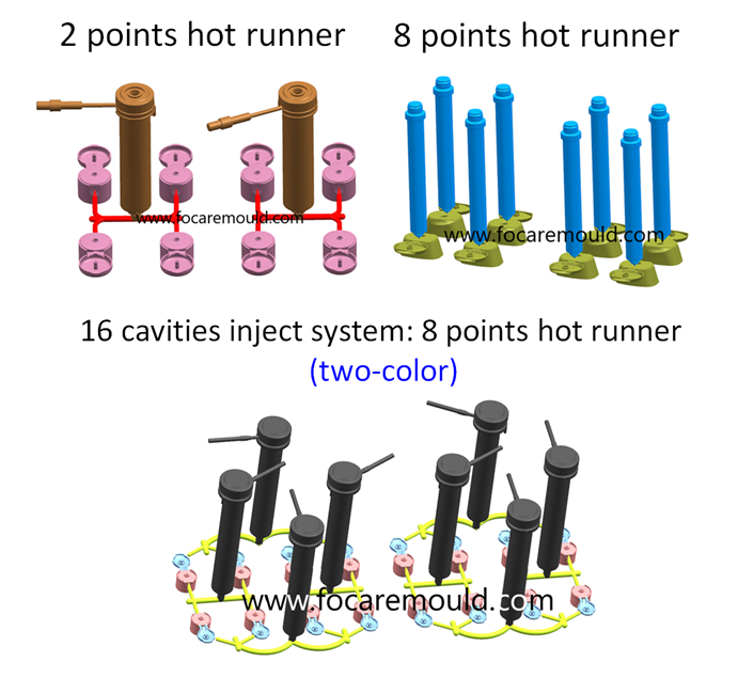

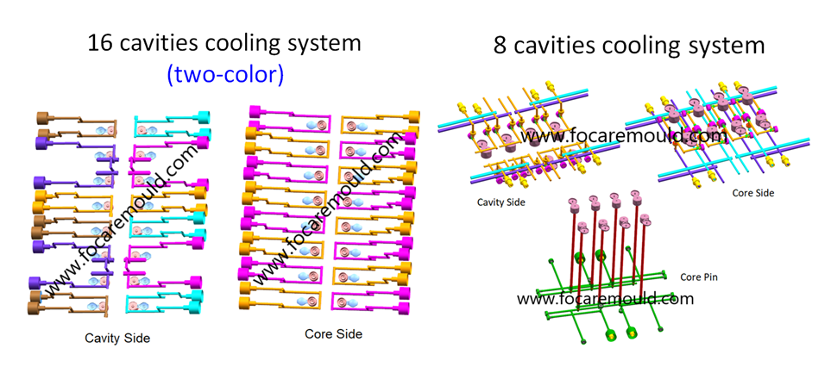

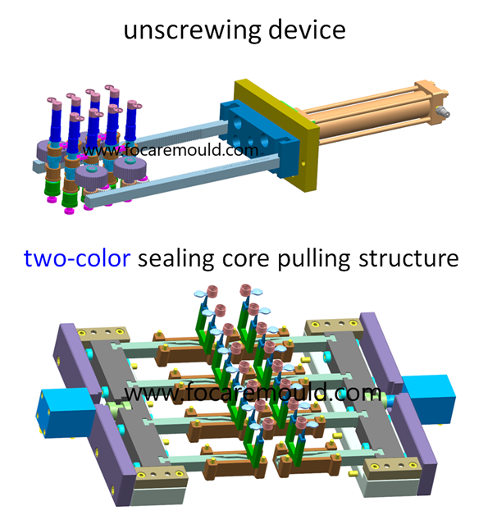

2. Mold structure design: The production efficiency and smoothness are the most important things for manufacturer. Design molds consummate cooling system, smoothly eject system, well-designed injection system are the key points to make the cycle time shorter. Besides, there are some complicated structures, such as core pin pulling, or unscrewing-device, which need accurate design and calculation.

3. Mold steel quality: Normally, the flip-top cap plastic injection mold is very detailed, most of the important spare parts such as core pins, core base are very small that should pass complex processing program. Based on the reasons, it is important to select strong, tough steel that can make mold high-quality, and prolong the mold life.

Before we quote the price, here are some basic requirements of flip-top cap plastic injection mold for customers to decide first:

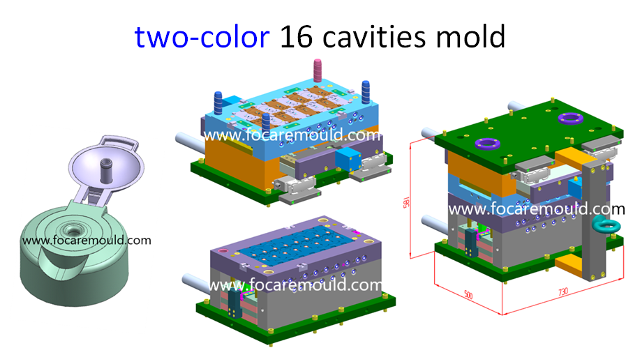

A. Product design: The size, the type, with or without thread, single-color or two-color. (Depends on market and customer preference.)

B. Cavities: 8 cavities, 16 cavities or 32 cavities. (Depends on market demand and customer’s plastic injection machine performance.)

C. Injection: All-hot runner or semi-hot runner. (Depends on cost consideration. All-hot runner system can avoid the waste of material that helps to save material cost; however, the initial investment will be higher.)

Focare Mould, we specialize in making high-end daily necessities plastic injection molds in single-color and two-color. Among them, flip-top cap plastic injection mold is one of the detailed products that especially require technique and experience.

Focare Mould, we are definitely your best choice.