-

Plastic Bicycle Bottle Holder Injection Mould

A bottle cage is device used to affix a water bottle to a bicycle. Composed of plastic, aluminum, stainless steel, titanium or carbon fiber. Plastic bottle cages generally are made by rigid PVC which in particular has very high density for a plastic making it extremely hard and generally very strong. It is also readily available and very economical which combined with the long-lasting characteristics of most plastics make it an easy choice for many industrial applications. Some of the most significant properties of Polyvinyl Chloride (PVC) are: 1. Density: PVC is very dense compared to most plastics (specific gravity around 1.4) 2. Economics: PVC is readily available and cheap. 3. Hardness: Rigid PVC is very hard. 4. Strength: Rigid PVC has extremely good tensile strength.

Read More -

Two-color Plastic Portable & Collapsible Bathtub Injection Mold

By simply just follow the under four steps to do before or after using it: - turn the bathtub up or upside down - pop-up or fold with hand press - restore or remove the leg supports - turn it up for using. After using, turn it over and put it away

Read More -

Plastic kitchen vegetable and fruit storage trolley mould

6.Four-corner 360-degree plastic storage pulley movement design: The durable kitchen storage pulley wheel has a good mechanical labor-saving design, which can easily move the shelf. Balanced and stable sliding to any place you want, plastic storage trolley wheels can be competent whether it is wooden floor, tiled floor, concrete floor, etc .... without harming the floor surface.

Read More -

Refrigerator drawer plastic injection mold

Refrigerator drawer belongs to large-scale production plastic mold and requires high standard, so single cavity injection molding process and point gate hot runner are used in injection molding. For the parting surface of the drawer, it determines the structural form of the whole mold, so this design adopts the injection mode of the double parting surface to achieve the stability of the whole refrigerator drawer structure.

Read More -

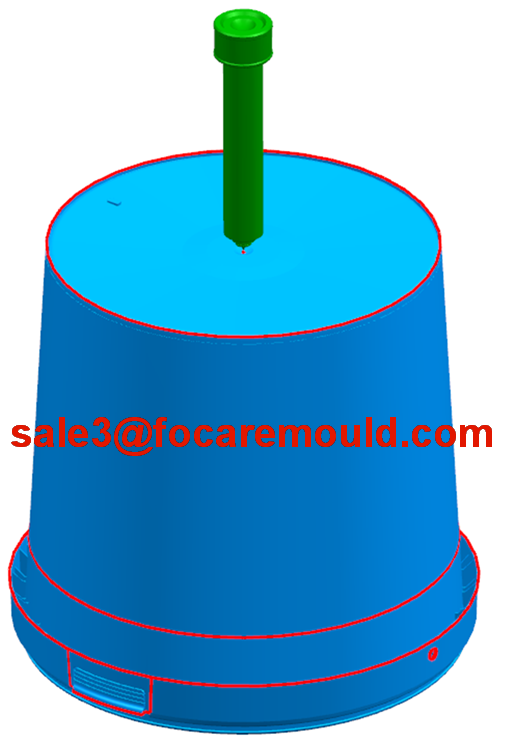

Plastic paint bucket injection mold

There are several methods to test plastic paint buckets: 1. Airtightness test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, the bucket should be dumped. The lid should not fall off or leak. 2. Push-down test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, stack three buckets together, tilt them and let the buckets fall; the bucket lid cannot be opened. 3. Drop test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, drop it at an inclined angle of 45 ° at the bottom of the bucket at a height of 80cm. The lid cannot be separated from the bucket, and the bottom of the bucket must not be broken. 4. Special test: After assembling the matching lid to fill the bucket with 80% of water, stack 4 buckets without deformation for 7 days. 5. Side leak test: Fill the bucket with 80% of water and leave to stand for 30 minutes without leakage; turn to the opposite side for 30 minutes without leakage.

Read More -

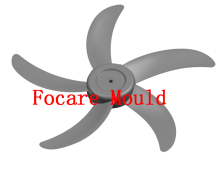

Plastic fan blade injection mold

The whole structure has the following advantages: 1. The rigidity of molding products is good. 2. mold is easy to be assembled and disassembled. 3. The number of mold parts is small. 4. There are few parting marks on the surface of the product. 5. The external dimension of the mold can be reduced.

Read More -

Hair dryer plastic injection mold

Focare mould adopts customized mould base design, which greatly improves mould production efficiency. According to the material of the hair dryer product, the mould core part and cavity part are made of high-quality S136 steel, which has excellent corrosion resistance and polishing performance. In the process of processing and hardening, it has good dimensional stability and can ensure the assembly performance of all parts of the product.

Read More -

Classical Plastic Flower Pot Injection Mould

The shape of the flower pot can be customized according to the customer's needs. If you are interested in the flower pot mold, please contact us. We can design the ideal product shape for the customer, and carry out mold design, as well as professional mold processing and production, and testing. Stencil. We have a set of high-precision CNC machines, and we are proud of our ability to make high quality plastic injection molds. Providing plastic injection molds with the highest CP value and creating a win-win situation has always been our goal.

Read More -

Foldable/Portable Outdoor Camping/Cleaning Double Component Bucket Mould

Product Size: 46x30.3x20.4cm Material: PP+TPE Weight: 580G - Durable and tough material, essential barrels for home camping. - Collapsible storage, clean and neat, does not take up space - Excellent texture, abrasion resistance, high and low temperature resistance, good grip

Read More