- Home

- >

- Products

- >

- Household Mold

- >

- Hair dryer plastic injection mold

Hair dryer plastic injection mold

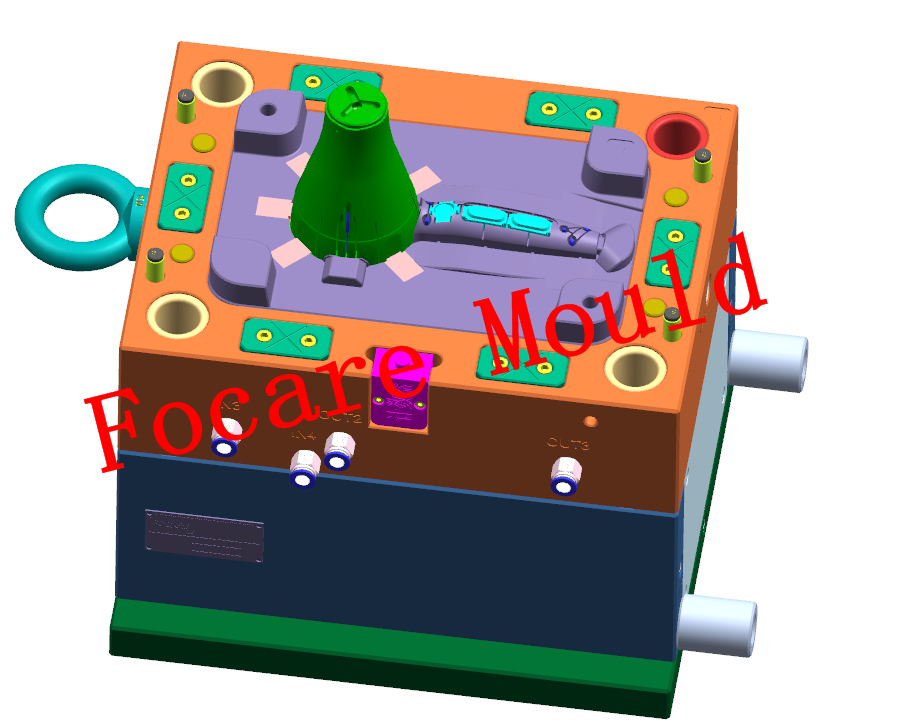

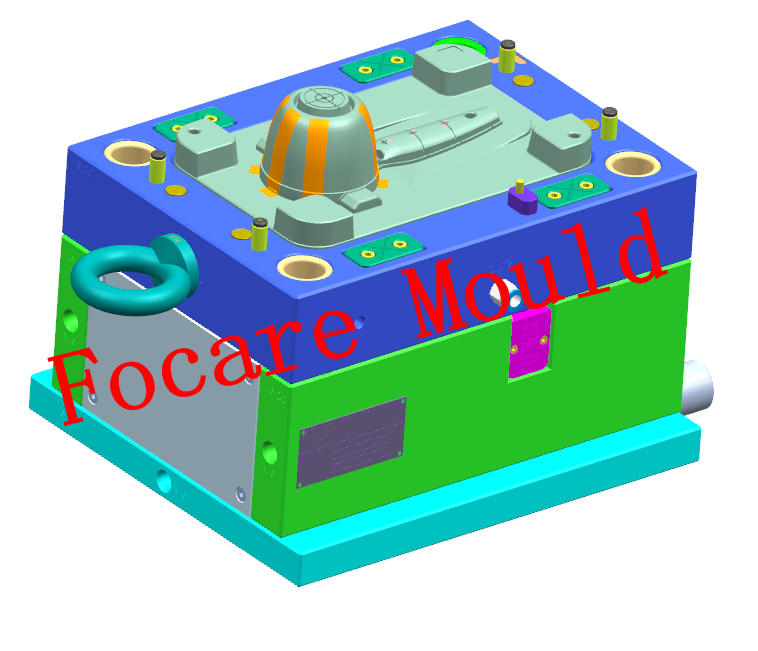

Focare mould adopts customized mould base design, which greatly improves mould production efficiency. According to the material of the hair dryer product, the mould core part and cavity part are made of high-quality S136 steel, which has excellent corrosion resistance and polishing performance. In the process of processing and hardening, it has good dimensional stability and can ensure the assembly performance of all parts of the product.

Hair dryer is mainly used for drying and shaping hair, but it can also be used for local drying, heating and physiotherapy in laboratory, physiotherapy room, industrial production, art and other aspects.

According to the type of motor it uses, it can be divided into AC series excitation type, AC shaded pole type and DC permanent magnet type. The advantages of series hair dryer are large starting torque, high speed, suitable for manufacturing high-power hair dryer; the disadvantages are large noise, commutator has certain interference on telecommunication equipment. The advantages of the shaded pole hair dryer are low noise, long service life and no interference to the telecommunication equipment; the disadvantages are low speed, poor starting performance and heavy weight. The advantages of permanent magnet hair dryer are light weight, high speed, simple manufacturing process, low cost, good quality and low price.

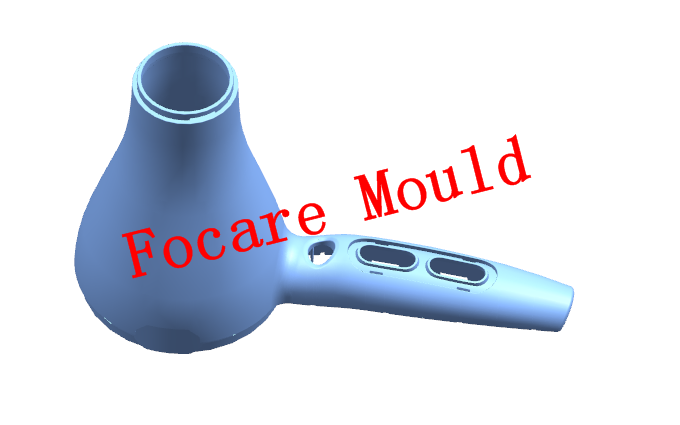

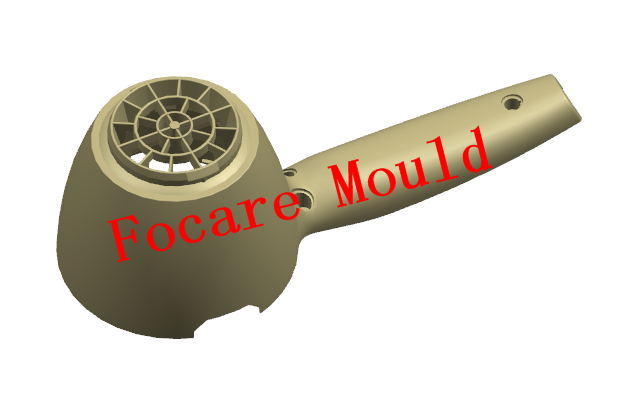

Although there are many kinds of hair dryers, their structures are the same and the same. They are all composed of hair dryer’s shell, handle, motor, fan blade, electric heating element, wind shield, switch, power cord, etc.

Focare mould adopts customized mould base design, which greatly improves mould production efficiency. According to the material of the hair dryer product, the mould core part and cavity part are made of high-quality S136 steel, which has excellent corrosion resistance and polishing performance. In the process of processing and hardening, it has good dimensional stability and can ensure the assembly performance of all parts of the product.