- Home

- >

- Products

- >

- Household Mold

- >

- Plastic fan blade injection mold

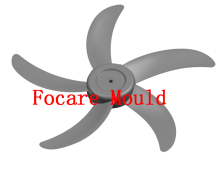

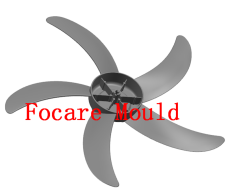

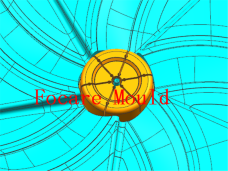

Plastic fan blade injection mold

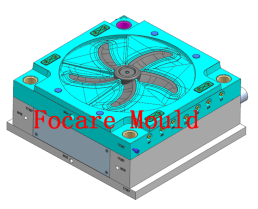

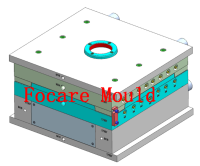

The whole structure has the following advantages:

1. The rigidity of molding products is good.

2. mold is easy to be assembled and disassembled.

3. The number of mold parts is small.

4. There are few parting marks on the surface of the product.

5. The external dimension of the mold can be reduced.

Electric fan, it is a kind of household appliance that uses electric motor to drive the plastic fan blade to rotate and accelerate the air circulation, mainly used for cooling, relieving summer heat and circulating air. It is widely used in families, classrooms, offices, shops, hospitals and hotels.

Electric fan is a kind of daily essential thing which need to be produced in large quantities. It also has close contact with people, so it must be made from non-toxic and non-harmful material. Considering that there is no high strength and shrinkage requirement for the plastic fan blade, normally we choice ABS as the material for the plastic fan blade.

ABS has the characteristics of good process ability, high surface finish, good painting and dyeing, and it can be electroplated into many colors which can help sales of electric fans.

The wall thickness of the plastic fan blade is uneven, the requirements of dimensional accuracy, the surface quality and the dimensional stability are really high, and so the requirements for the plastic injection mold and equipment are also high.

According to the structural characteristics of the plastic fan blade, there is no such structure as forming rod and screw type. But the surface of the plastic fan blade is complex and the appearance is required to be beautiful. The hub core is designed as an integral structure. This structure is easy to ensure the coaxiality of the plastic fan blade installation shaft and facilitate the overall heat treatment. The whole structure has the following advantages:

1. The rigidity of molding products is good.

2. mold is easy to be assembled and disassembled.

3. The number of mold parts is small.

4. There are few parting marks on the surface of the product.

5. The external dimension of the mold can be reduced.