-

Two-color foldable dish rack plastic injection mold

This two-color foldable dish rack is made by PP+TPE which make it to be retractable. When we don’t need to use it, we can easily fold it up. The height of this two-color foldable dish rack after unfolding is only 5.5 cm, we can tuck it in any small gap. The two-color foldable dish rack has humanized drainage design which can help fast draining. There is a two-color tray at the bottom, so we don’t worry about the water flowing everywhere although the two-color foldable dish rack is not near the sink.

Read More -

Fantastic plastic rattan laundry basket injection mold

(1) Rattan style design: The appearance of Fantastic plastic laundry basket is imitation rattan style design, novel style and high grade. The elegant appearance can be matched with any series of furniture. Fantastic plastic Rattan laundry basketis easy to store clothes and debris, wherever it fits.

Read More -

Two-color spatula plastic injection mold

Usually the cake spatula is assembled. The handle plastic is made of ABS or PP with a silicone rubber blade. But now we can say goodbye to the old design and the new one is a one-piece design; it means it is a two-color spatula. Two-color spatula brings together design and innovative energy, hoping to add multiple and modern elements, seeking balance in quality, aesthetics and function, and giving consumers a comfortable experience. The flexible TPE head of the two-color spatula is stain-resistant, which is very suitable for seasoning sauces, cream or batter. The two-color spatula is equipped with a plastic handle with a firm and comfortable grip. It has a hole for hanging which is helpful for saving space.

Read More -

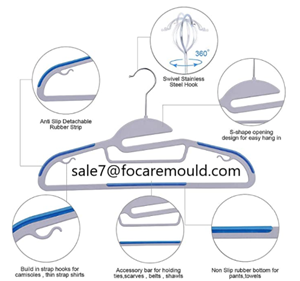

Two-color non-slip hanger plastic injection mold

There are two ways to manufacture two-color non-slip hanger, by over-molding or bi-injection. Over-molding is simpler; however, it needs two plastic injection molds and two plastic injection machines, which takes more time and extra cost for labor. Bi-injection needs only one two-color plastic injection mold and one two-color plastic injection machine, it saves a lot manufacturing time and decreases the deformity of product drastically that helps avoid material waste.

Read More -

Two-color collapsible foot bath bucket plastic injection mold

The two-color collapsible foot bath bucket is made of PP+TPE, which make the bucket not only foldable, but also mixed colors. The bucket looks more attractive to everyone than an ordinary plastic bucket. We only need to fold one side first, and then fold the other side; the height of the bucket is only 7 cm after folding. This size makes the two-color collapsible foot bath bucket is easy to be storage after folding. The bucket can be placed freely in any corner. With the notch design in the bottom, the bucket can be hung on the wall to save space after folding.

Read More -

Plastic storage drawers injection mold

Most of the plastic storage drawers are made of PP plastic. PP plastic, chemical name: polypropylene PP is a crystalline polymer. PP is the lightest in common plastics the density is only 0.91g / cm3 (smaller than water). Among general-purpose plastics, PP has the best heat resistance. Its heat distortion temperature is 80-100 °C and it can be boiled in boiling water. PP has good stress resistance, is not easy to have crack, and has a long service life. The overall performance of PP is better than PE. PP products are light weight, good toughness, and good chemical resistance.

Read More -

Clear Plastic Injection Molds of Jugs, Wine Cup, Salad Bowl, Cup and Plate

Clear plastic injection molding parts usually made in GPPS, PC, PMMA(Acrylic), AS(SAN), PET, Tritan and so on. Due to the high light transmittance, clear plastics must have strict requirements on the surface quality of plastic products, without any markings, pores, and whitening. Defects such as haze, black spots, discoloration, poor gloss are not acceptable. Since most of the transparent plastics have high melting point and poor fluidity, it is often necessary to make suitable adjustments to the process parameters such as mold temperature, injection pressure, injection speed, etc. in order to ensure the surface quality of the product. Meanwhile, the surface of mold cores & cavities is required high mirror polishing to get shiny and clear products. High hardness of mold steel is necessary to avoid scratching during ejection

Read More