- Home

- >

- Products

- >

- Plastic Cup / Mug / Pitcher / Jug Mold

- >

- Clear Plastic Injection Molds of Jugs, Wine Cup, Salad Bowl, Cup and Plate

Clear Plastic Injection Molds of Jugs, Wine Cup, Salad Bowl, Cup and Plate

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Clear plastic injection molding parts usually made in GPPS, PC, PMMA(Acrylic), AS(SAN), PET, Tritan and so on.

Due to the high light transmittance, clear plastics must have strict requirements on the surface quality of plastic products, without any markings, pores, and whitening. Defects such as haze, black spots, discoloration, poor gloss are not acceptable.

Since most of the transparent plastics have high melting point and poor fluidity, it is often necessary to make suitable adjustments to the process parameters such as mold temperature, injection pressure, injection speed, etc. in order to ensure the surface quality of the product.

Meanwhile, the surface of mold cores & cavities is required high mirror polishing to get shiny and clear products. High hardness of mold steel is necessary to avoid scratching during ejection

The transparent household and tableware, such as water jugs, cups, plates, bowls and so on look like crystal and high-end quality. Most of the transparent plastics have high melting point and poor fluidity, it is often necessary to make suitable adjustments to the process parameters such as mold temperature, injection pressure, injection speed, etc. in order to ensure the surface quality of the product. Meanwhile, it is necessary to have high technology on plastic injection moulds design and manufacturing for making these high-end quality of clear plastic injection molding products.

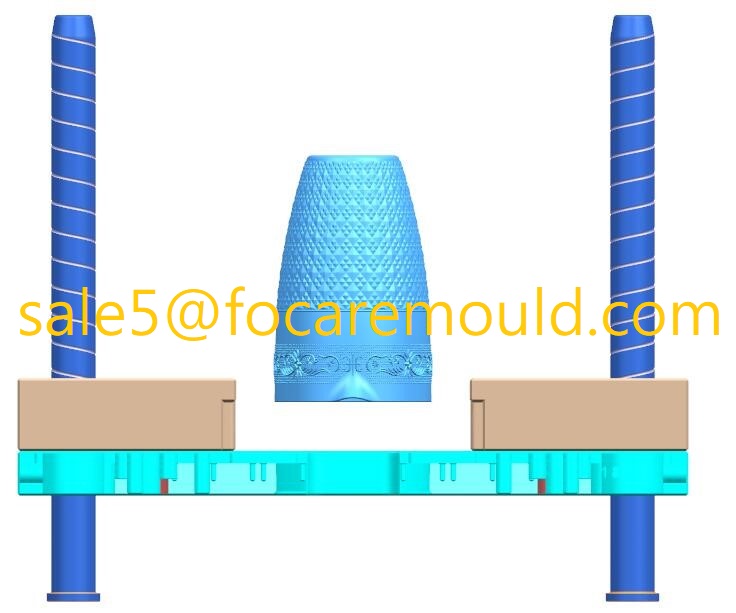

Barroco decorative pattern design, full of the Europe type palace retro atmosphere. The pattern with strong stereo and dimensional feeling, touching is wonderful. The product capacity is big, you can put a set on tea table to entertain a guest, beautiful and practical.

The mould structure of transparent water jug is required with 3 sliders, and eject by stripper plate which is very complicate design.

The pattern needs special processing, which must be complete and angular, otherwise the three-dimensional sense of the PS products will be insufficient, and the overall grad will be reduced. Therefore, good PS plastic injection mould assembly technology, processing and injection experience are required.