- Home

- >

- Products

- >

- Plastic Cup / Mug / Pitcher / Jug Mold

- >

- Two-Color Plastic Football Cup Injection Mould

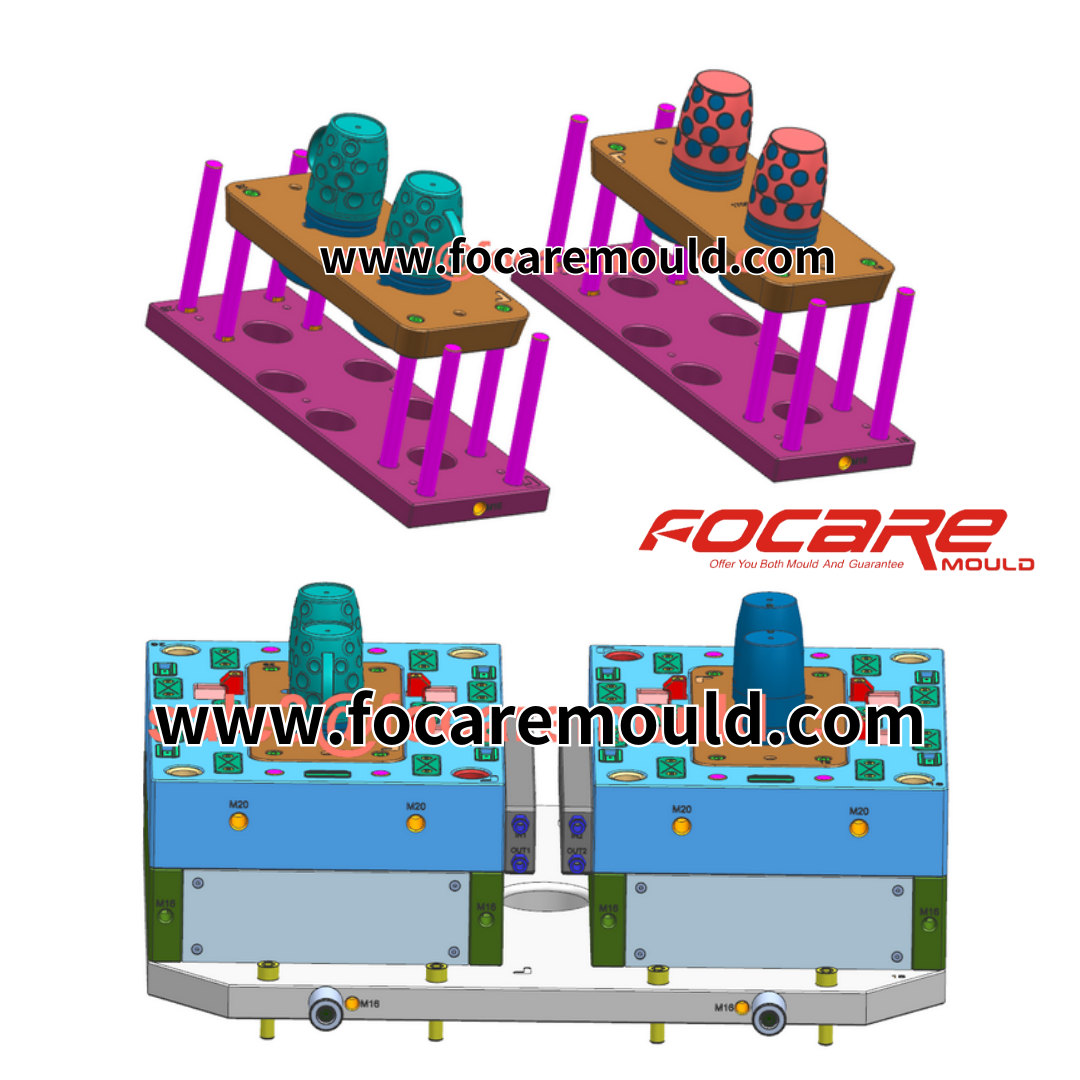

Two-Color Plastic Football Cup Injection Mould

Brand :Focare

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

This two-color plastic football cup is one of the most popular two-color injection molds at Focare Mould, especially the customers who are very fond of football. Its appearance is more beautiful than single color one. Besides, one can have more design idea by using the obvious color separation. From the transparent window of small circles, you can see a lot of football which let life feel colorful and pleasant.

This two-color plastic football cup is one of the most popular two-color injection molds in Focare Mould, especially the customers who are very fond of football.

Its appearance is more beautiful than single color one.

Besides, one can have more design idea by using the obvious color separation.

From the transparent window of small circles, you can see a lot of football which let life feel colorful and pleasant.

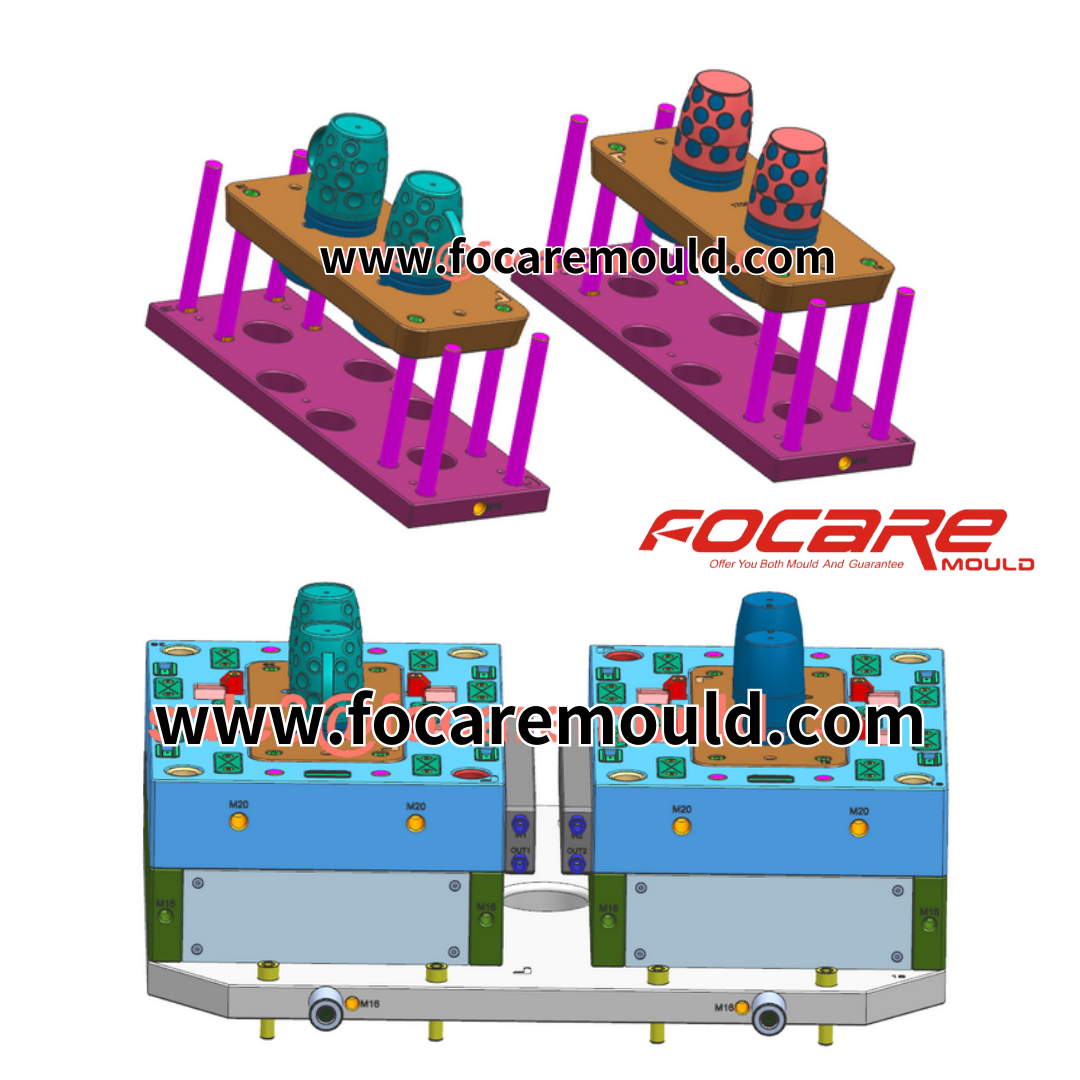

This plastic football cup is made by two-color of Polystyrene, PS which plastic material is one of the most widely used plastics because of its character of transparent.

In fact, it is not easy to fabricate plastic injection moulds for making transparent plastic material.

The hardness of steel on plastic injection mould shall be good enough in order to avoid scratching mark during ejection.

Hence, the grade of mold steel is very important for making transparent plastic products.

The selling price of Polystyrene (PS) plastic injection products is not so high, however, the cost of moulds is higher for making high-end crystal plastic products.

Moreover, it is not easy to make the small circles without second color over moulding.

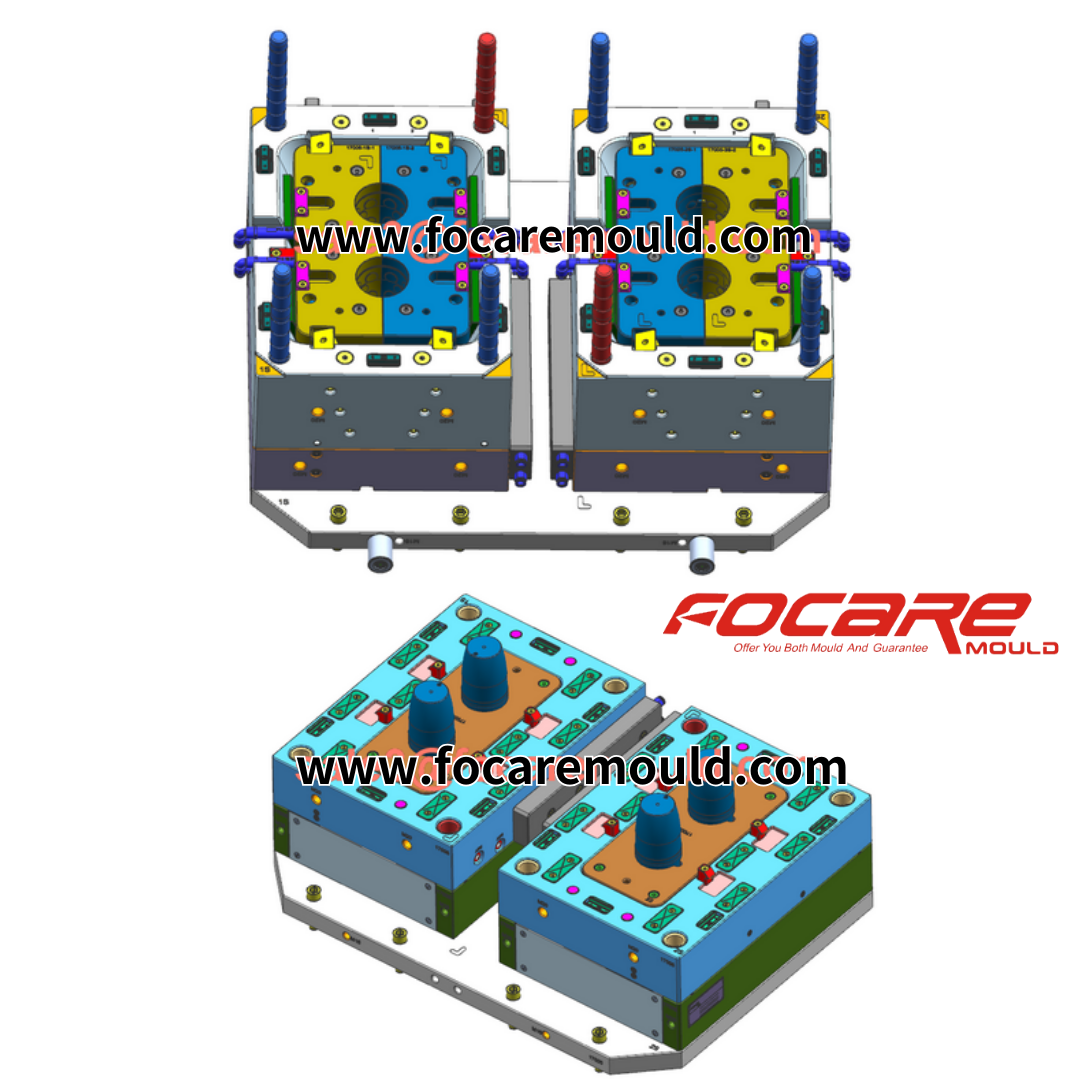

For this design of football mug, it is difficult to produce by traditional two-step injection, which produce the two colors with two different plastic injection moulding machines and moulds.

It is suggested to manufacture by one-step injection, produced with double color rotary table injection machines and mould.

1. Inject the inner color.

2. Open the mold.

3. Turn the mold 180 degrees to another side.

4. Close the mold.

5. Inject the outer color; meanwhile the other shot of inner color is injected at same time.

6. Hold the pressure, the inner and outer color has cooling in the same time.

7. Open the mold, eject the two-color mug.

8. Next shot continually.