- Home

- >

- Products

- >

- Household Mold

- >

- Two Color Houseware Mold

- >

- Two-Color Plastic Clothes Pegs

Two-Color Plastic Clothes Pegs

Brand :Focare

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

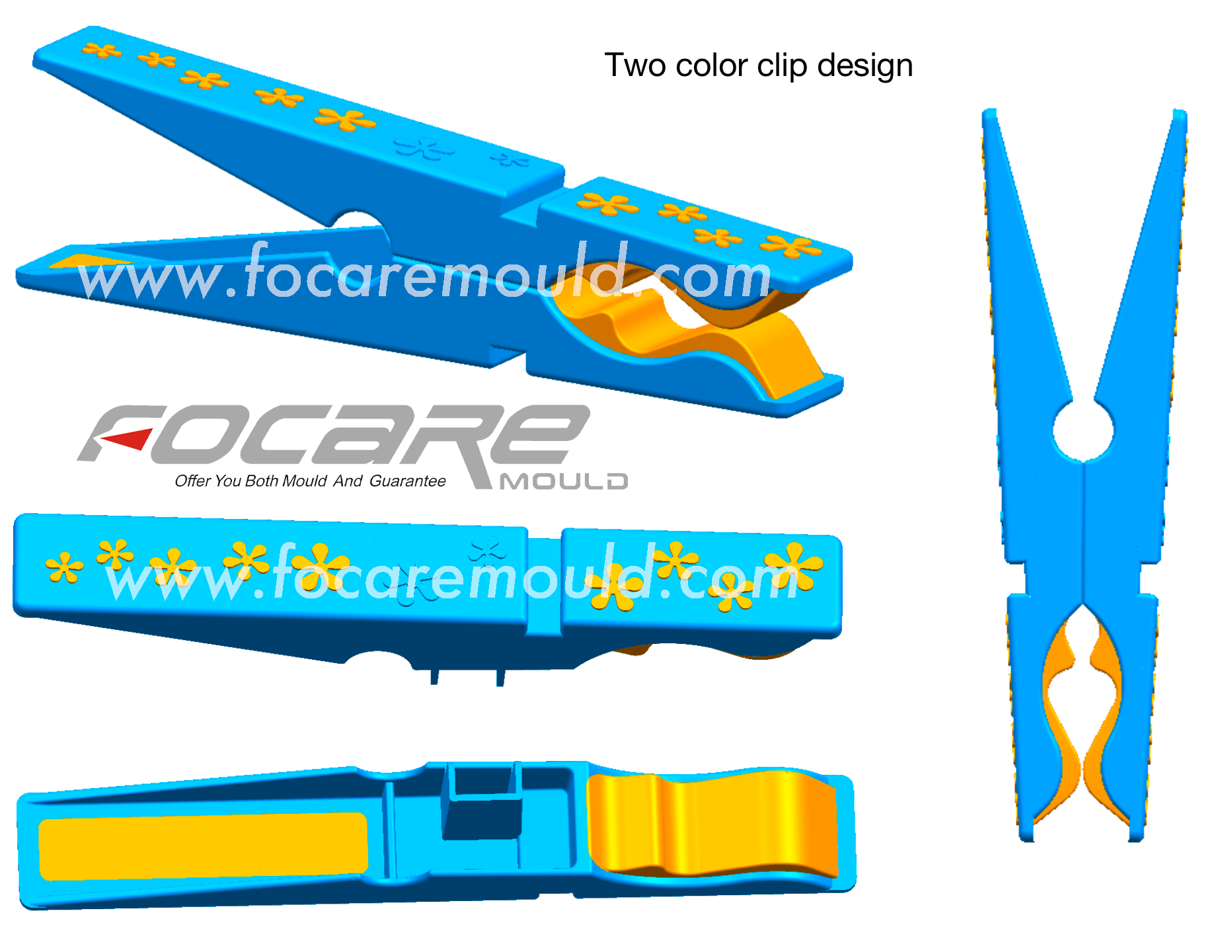

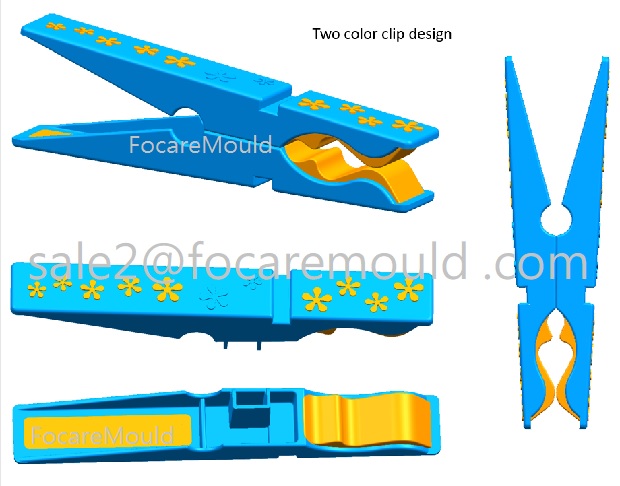

Now, many clothes-pegs or called clothespins, clothes clips are manufactured very cheaply by creating two interlocking plastic, in between which is often wedged a small spring. In order to increase the added-value of plastic clothes pegs, some maker developed colorful and fashionable two-color clothespins, which is combined with PP & TPE in one parts.

Now, many clothes-pegs or called clothespins, clothes clips are manufactured very cheaply by creating two interlocking plastic, in between which is often wedged a small spring. In order to increase the added-value of plastic clothes pegs, some maker developed colorful and fashionable two-color clothespins, which is combined with PP & TPE in one parts.

The reasons for making clothes clips with PP + TPE are as below:

1. Non-slip: The TPE part could clip clothes well without slip. Meanwhile, it is not easy to have pressing mark or scratch on clothes after clipping.

2. Colorful: The two-component clothes-pegs could be made with two different colors and different design which let plastic clothespins look more valuable.

3. Anti-rust: The plastic clothes clips won’t make rust as steel one.

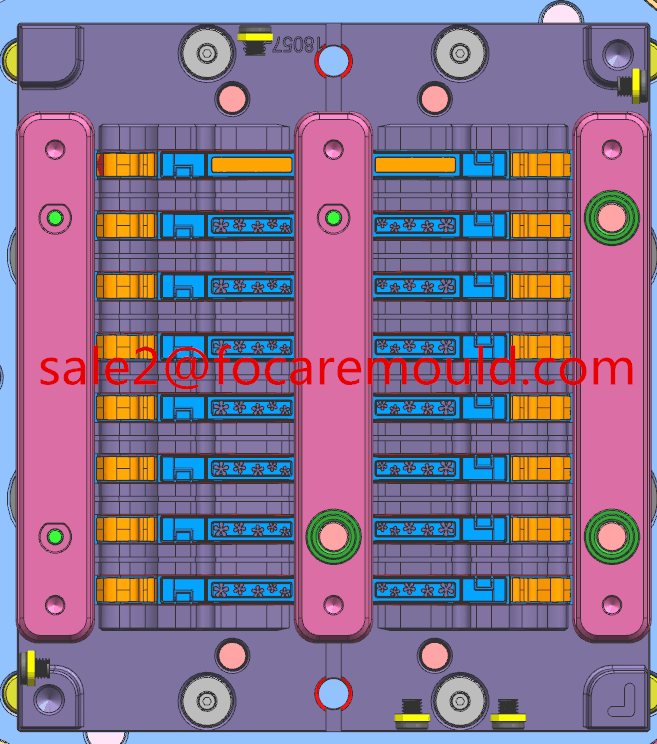

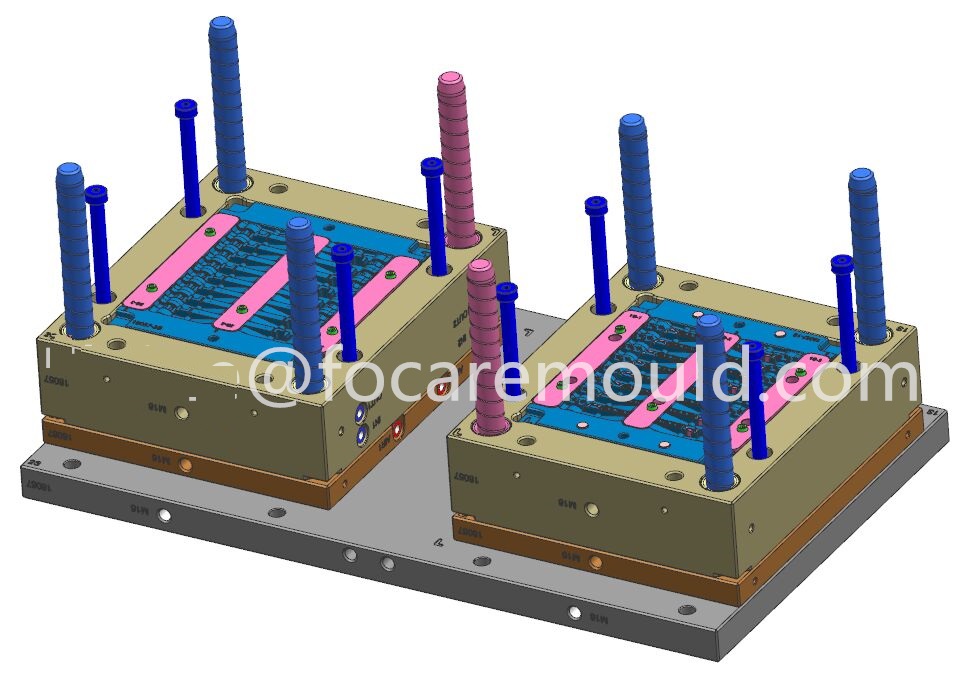

The two-color clothes pegs are made by two different injections, one is made by one-step of rotary-table moulding injection, and one is made by two-step over moulding injection.

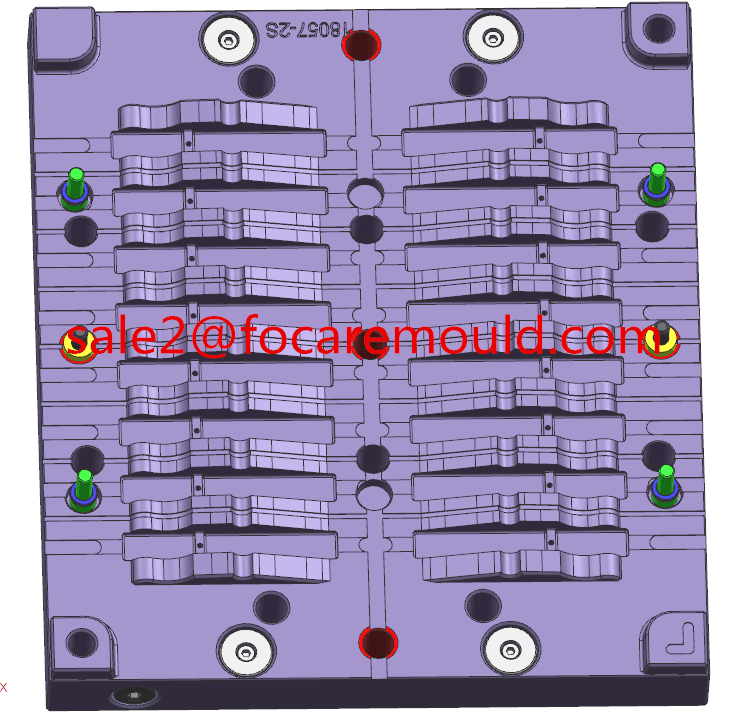

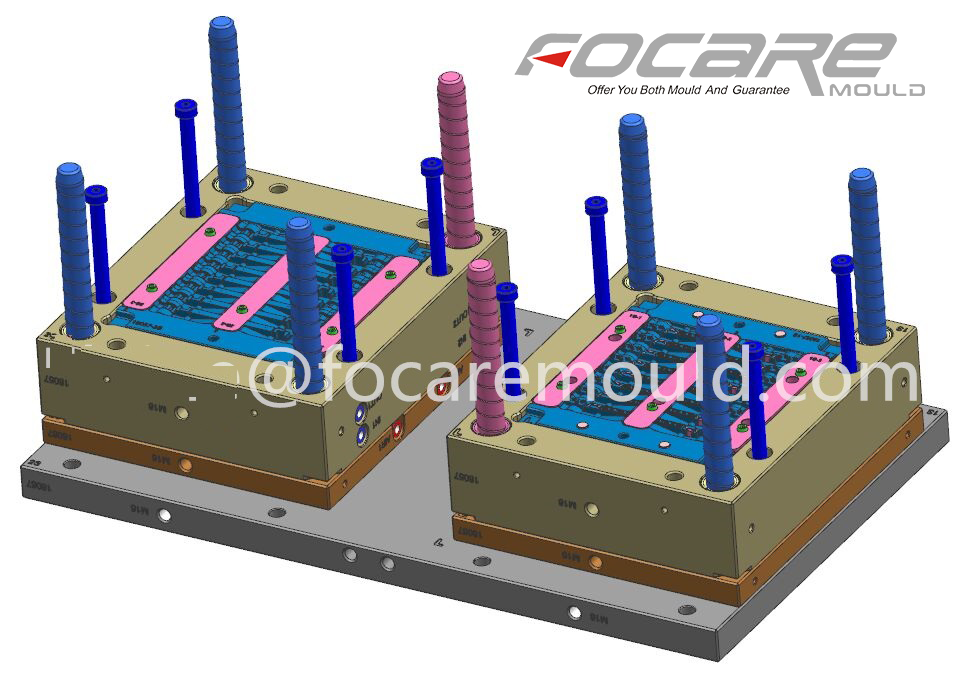

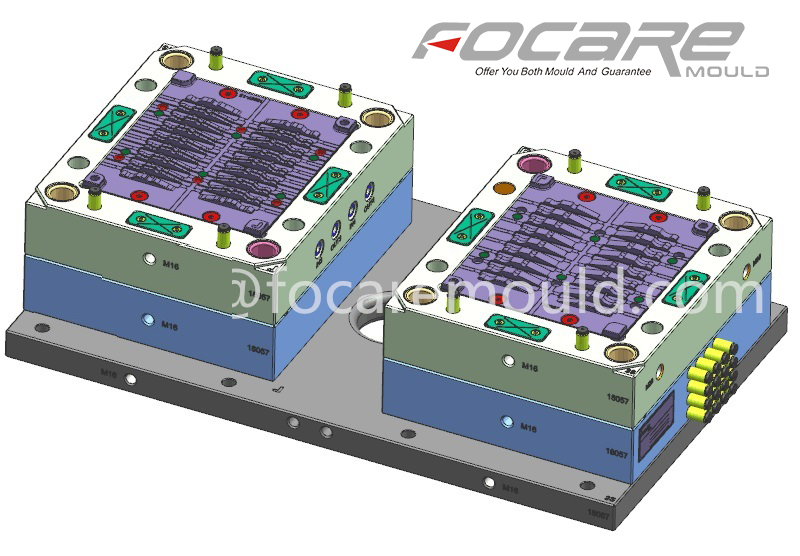

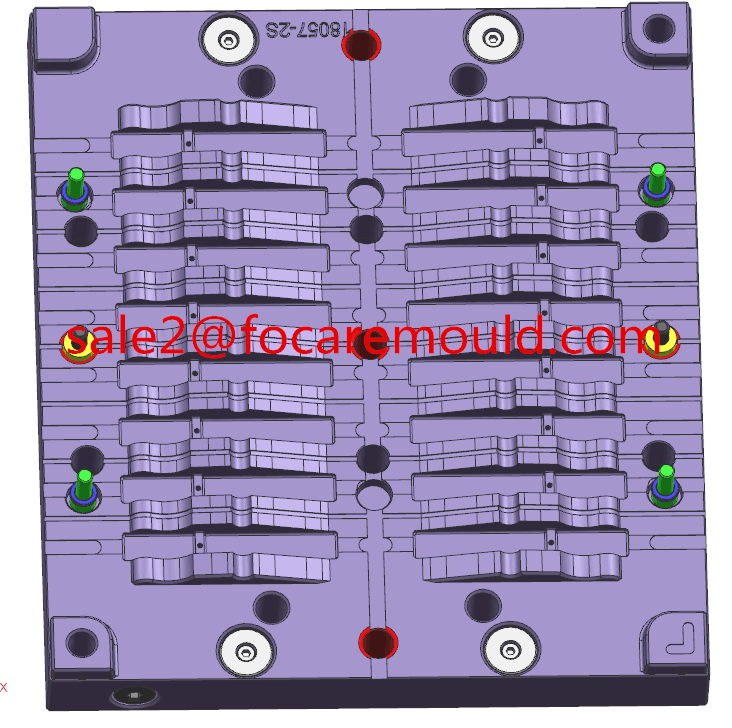

Rotary-table moulding is to make the double color rotary moulds, then make on two-color rotary table injection moulding machine to get finished two-component clothe-pegs at once. For this procedure, the cost of both machine and mold is higher, but more efficiency and low defectives.

Two-step over moulding injection means that the first injection of PP parts will be made by single color horizontal injection moulding machine. Secondly, operators will insert the PP parts on cavities of TPE moulds on vertical injection moulding machine, then make the TPE parts upon PP parts. This procedure looks lower cost, but it is necessary to have double space for loading injection machines, double labor cost, double cycle time on making one set of two-component clothespins. Meanwhile, the quality of finished two-color clips is not easy to control, will have more defectives.