- Home

- >

- Products

- >

- Caps Mold

- >

- Flip-Top Caps Mold

- >

- Two color flip top cap with in-mold auto-closing mold

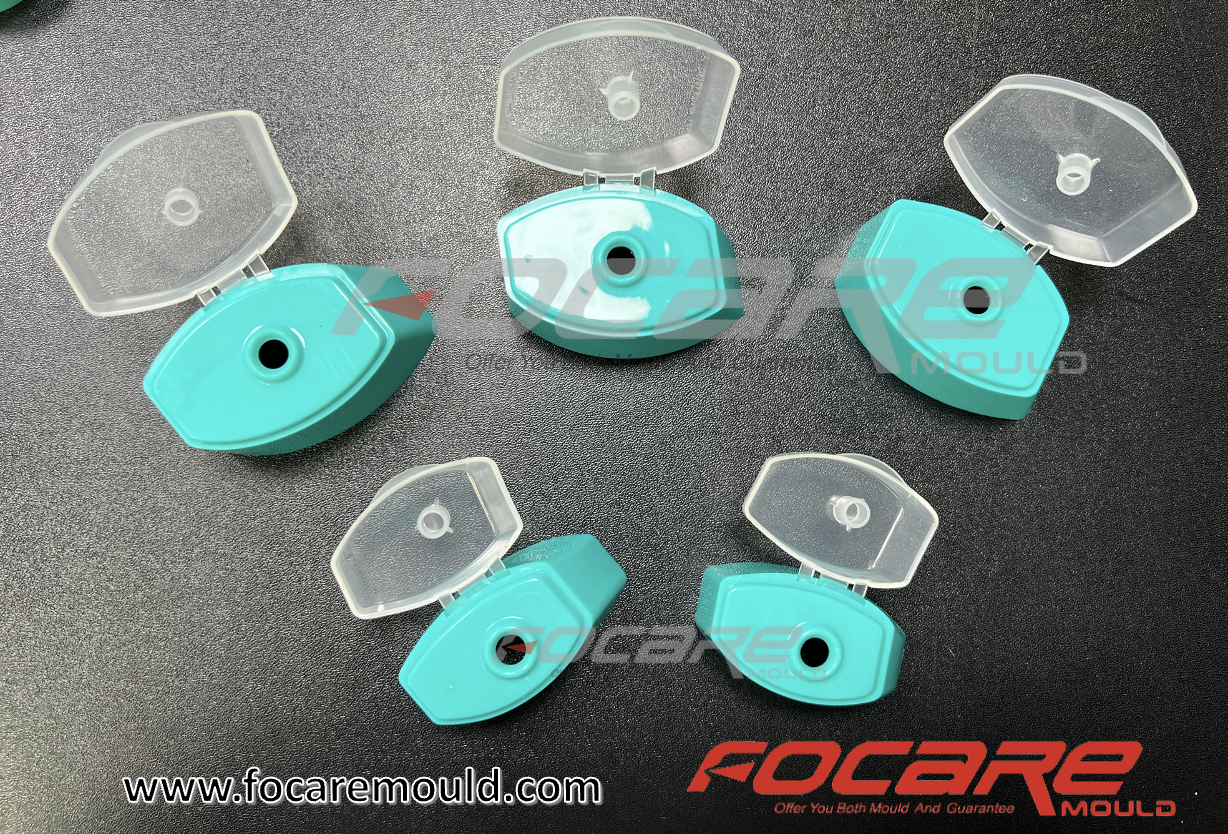

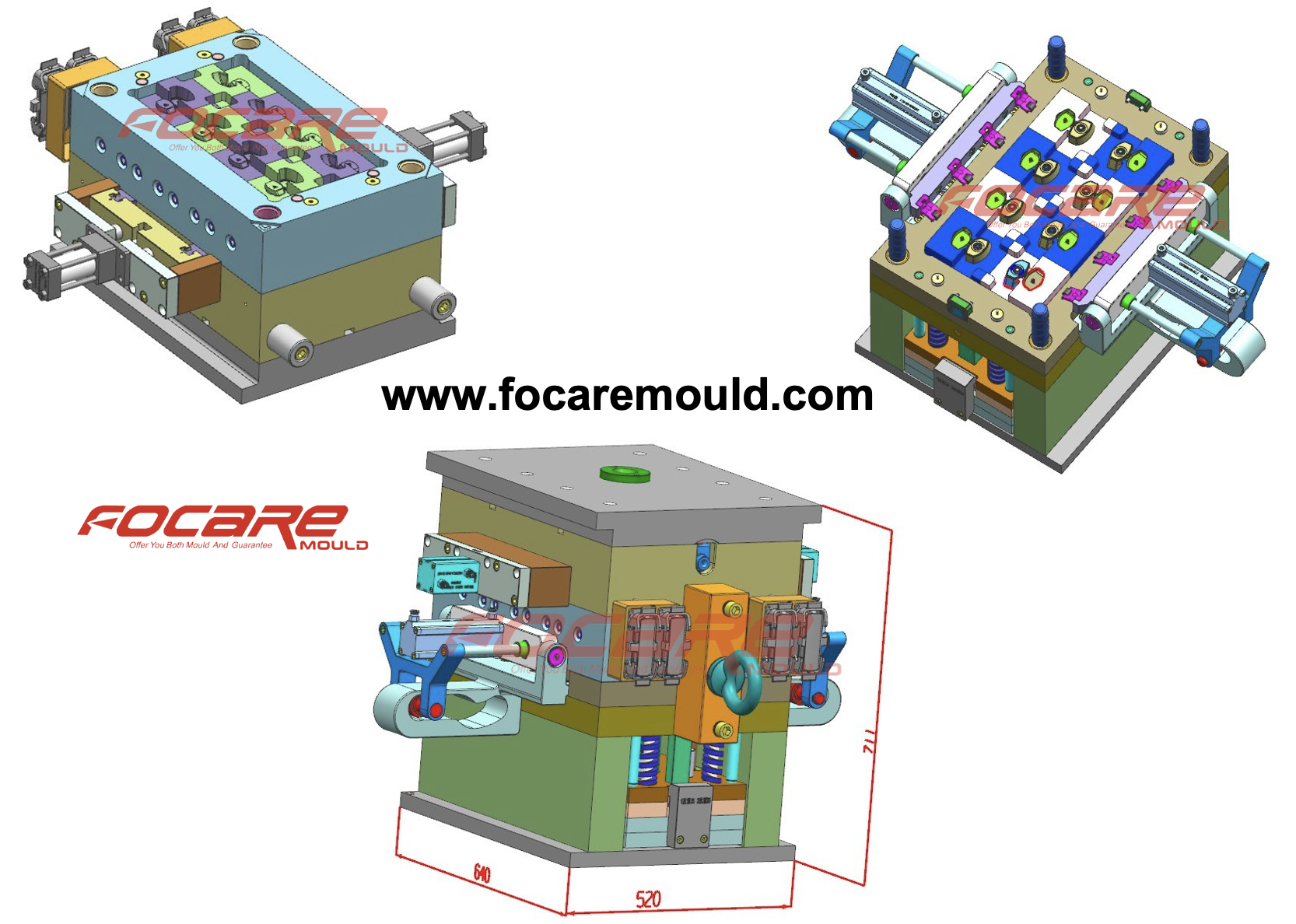

Two color flip top cap with in-mold auto-closing mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Two color flip top cap with in-mold auto-closing plastic injection mold

Product Material: PP+PP

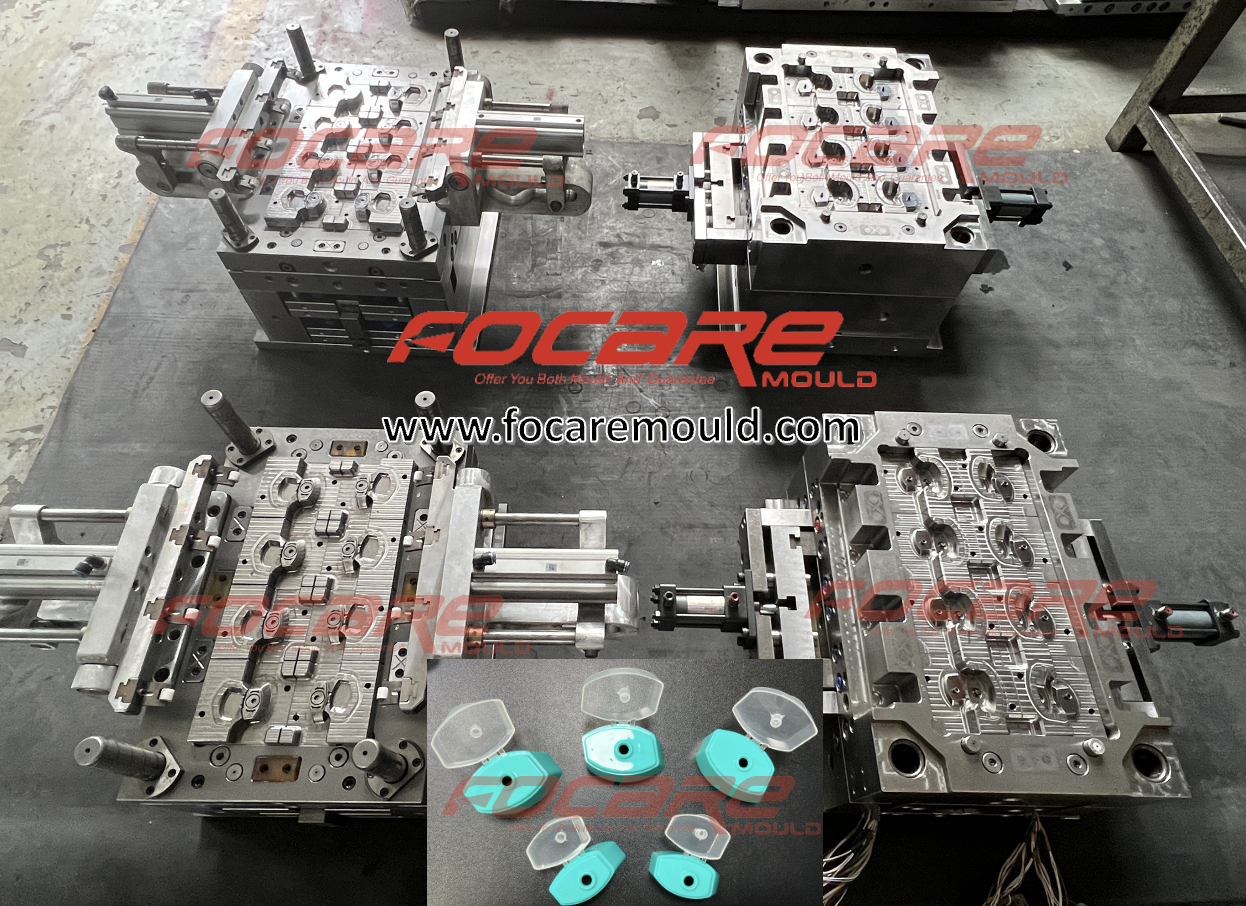

Mold Cavity : 8

Mold Steel: Germany imported steel DIN1.2344 with hardness 45-48HRC

Mold dimension: 520x640x676 mm

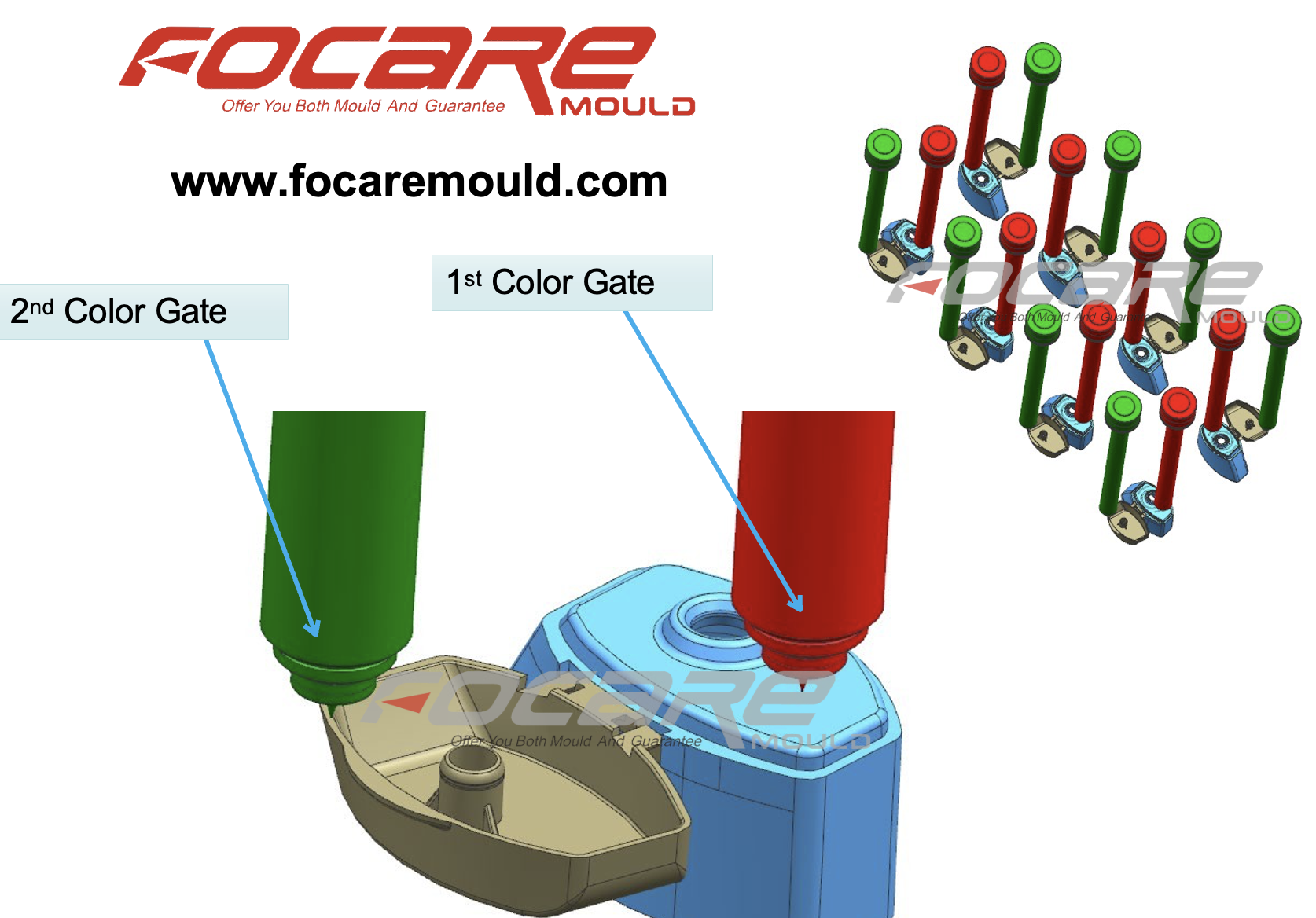

Hot runner system: 16-tips hot runner point gate

Mold size: 1650 kg

Suggested machine: 200 tons two color rotary table injection machine

Two color flip top cap with in-mold auto-closing plastic injection mold

Product Material: PP+PP

Mold Cavity : 8

Mold Steel: Germany imported steel DIN1.2344 with hardness 45-48HRC

Mold dimension: 520x640x676 mm

Hot runner system: 16-tips hot runner point gate

Mold size: 1650 kg

Suggested machine: 200 tons two color rotary table injection machine

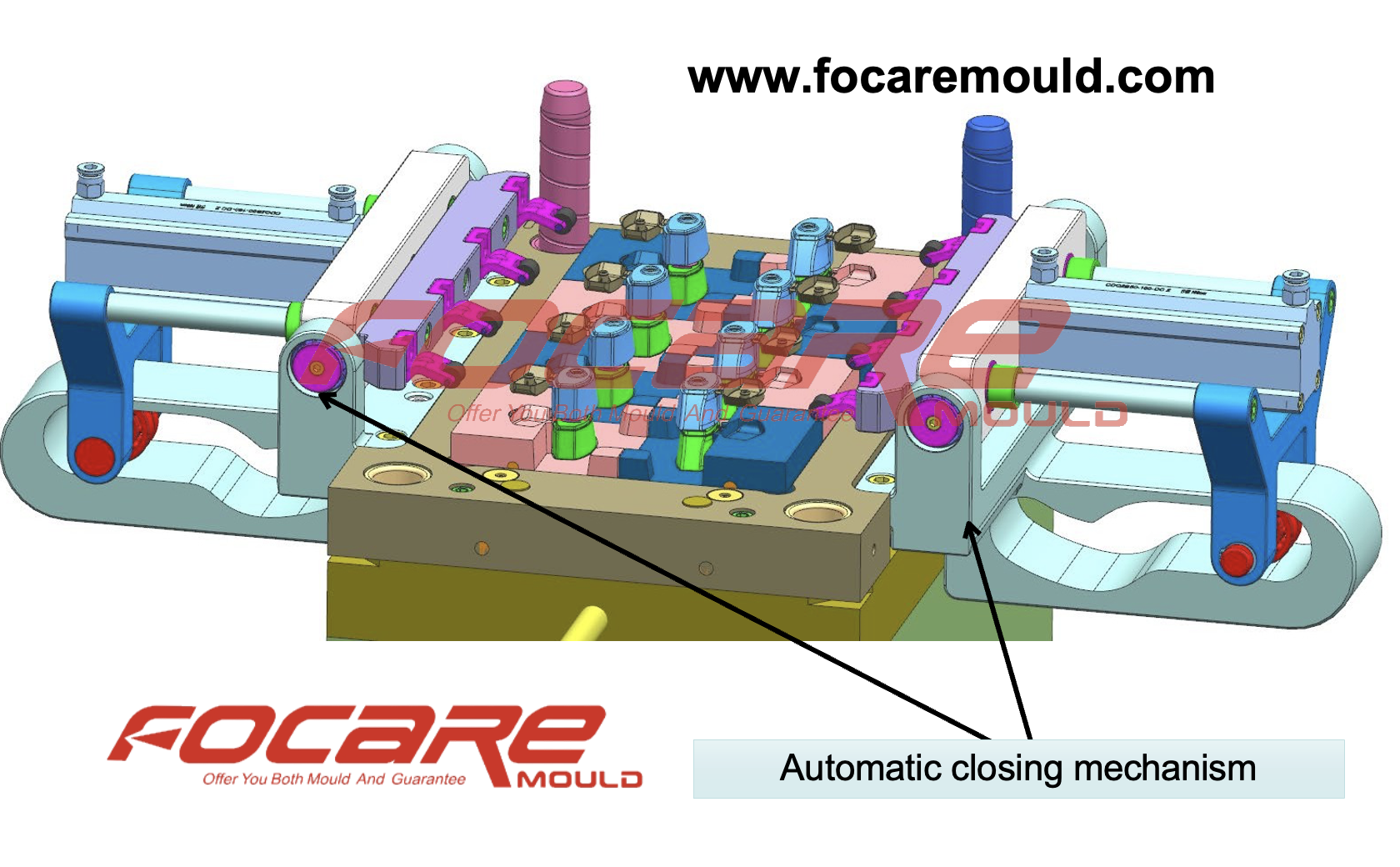

IMC (In Mold Closing System): Prior to product ejection, automatically assemble the product.

Advantage of IMC system: minimize the cycle time and maximum the production efficiency.

Plastic closures incorporating a flip top cap are in high demand for several categories and functions.

The need for quality and cost are driving plastics injection molding companies to search for improved cap closing solutions and best effect.

IMC has been offered for many years for flip-top closures, to fold the part over a living hinge and close the flip-top part before releasing it from the mold.

The primary advantages of this approach included precision of the closing motion, as well as the opportunity to fold the living hinge while the plastic is still hot, resulting in enhanced durability of the hinge and provides a good effect for the click of the flip top cap.

Moreover, this mechanism and system is to reduce the human contact with plastic product for hygienic reasons.

Before we quote the price, here are some basic requirements of flip-top cap plastic injection mold for customers to decide first:

A.Product design: The size, the type, with or without thread, single-color or two-color. (Depends on market and customer preference.)

B.Cavities: 8 cavities, 16 cavities or 32 cavities. (Depends on market demand and customer’s plastic injection machine performance.)

C.Injection: All-hot runner or semi-hot runner. (Depends on cost consideration. All-hot runner system can avoid the waste of material that helps to save material cost; however, the initial investment will be higher.)

Focare Mould, we specialize in making high-end daily necessities plastic injection molds in single-color and two-color.

Among them, flip-top cap plastic injection mold is one of the detailed products that especially require technique and experience.

Focare Mould china mold maker, we are definitely your best choice.

Focare Mould – China two color flip top cap mold maker, plastic clousure mold maker, in-mold closing flip top cap mold maker,china leading mold maker, if you are looking for a professional plastic mold maker in China who can provide you high quality two color mold, double color mold, two component mold,2K mold, multi color mold, and two color injection molding service, we will be your best choice.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services