- Home

- >

- Products

- >

- Plastic Chair & Table Mold

- >

- Rattan Chair Plastic Injection Mould

Rattan Chair Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :300 molds per year

The plastic rattan chair biggest selling point is its appearance, which is exactly like a bamboo woven chair. However, the plastic rattan chair can improve the biggest weakness of bamboo chair: useful life. The bamboo woven chair is easy to break that has to be replaced within years, also the broken bamboo is likely to scratch customers. The size of plastic rattan chair is 63X53X53mm and the weight is 2.5kg. It is big but light, and is durable, strong, easy to clean, beautiful, and colorful.

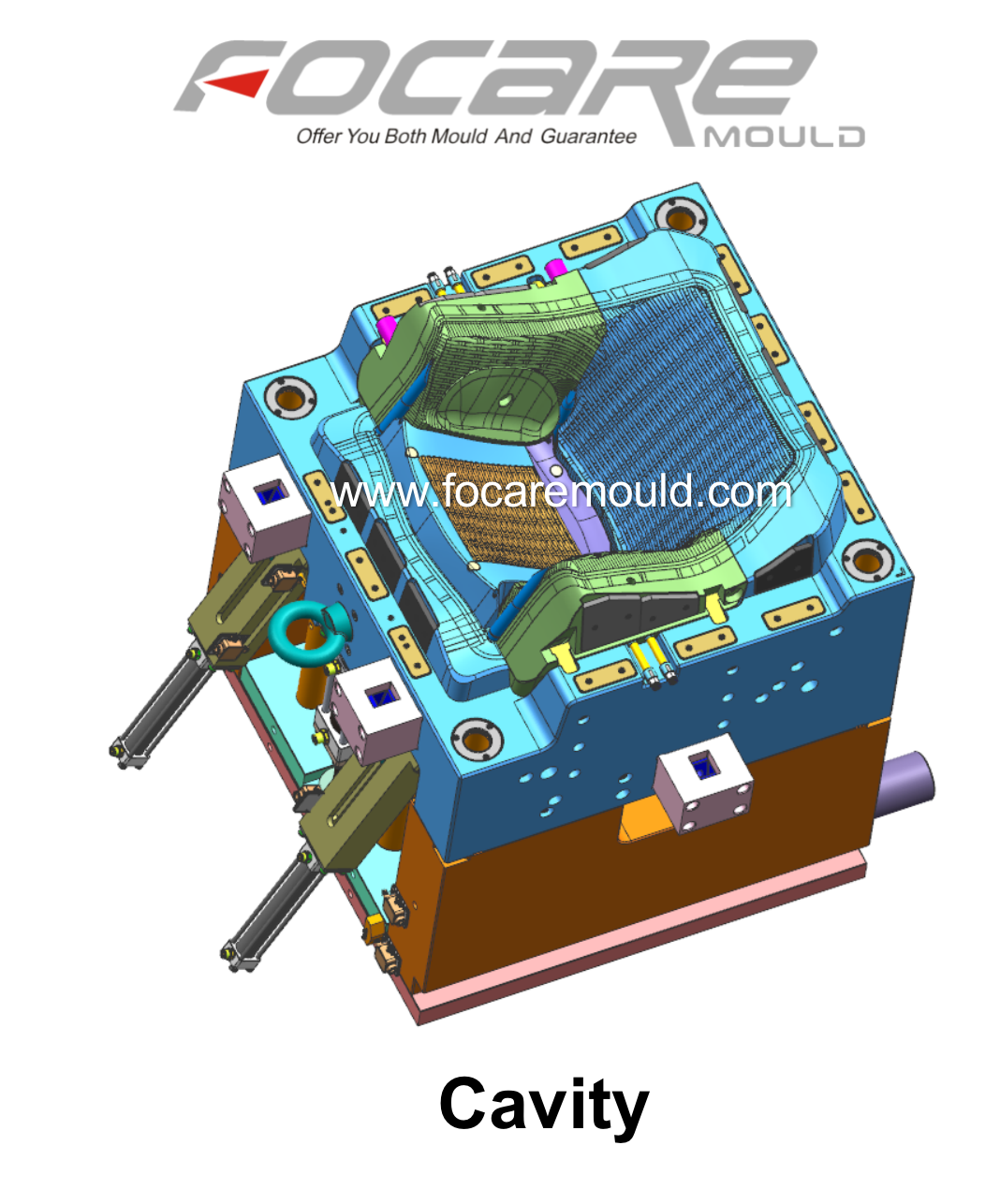

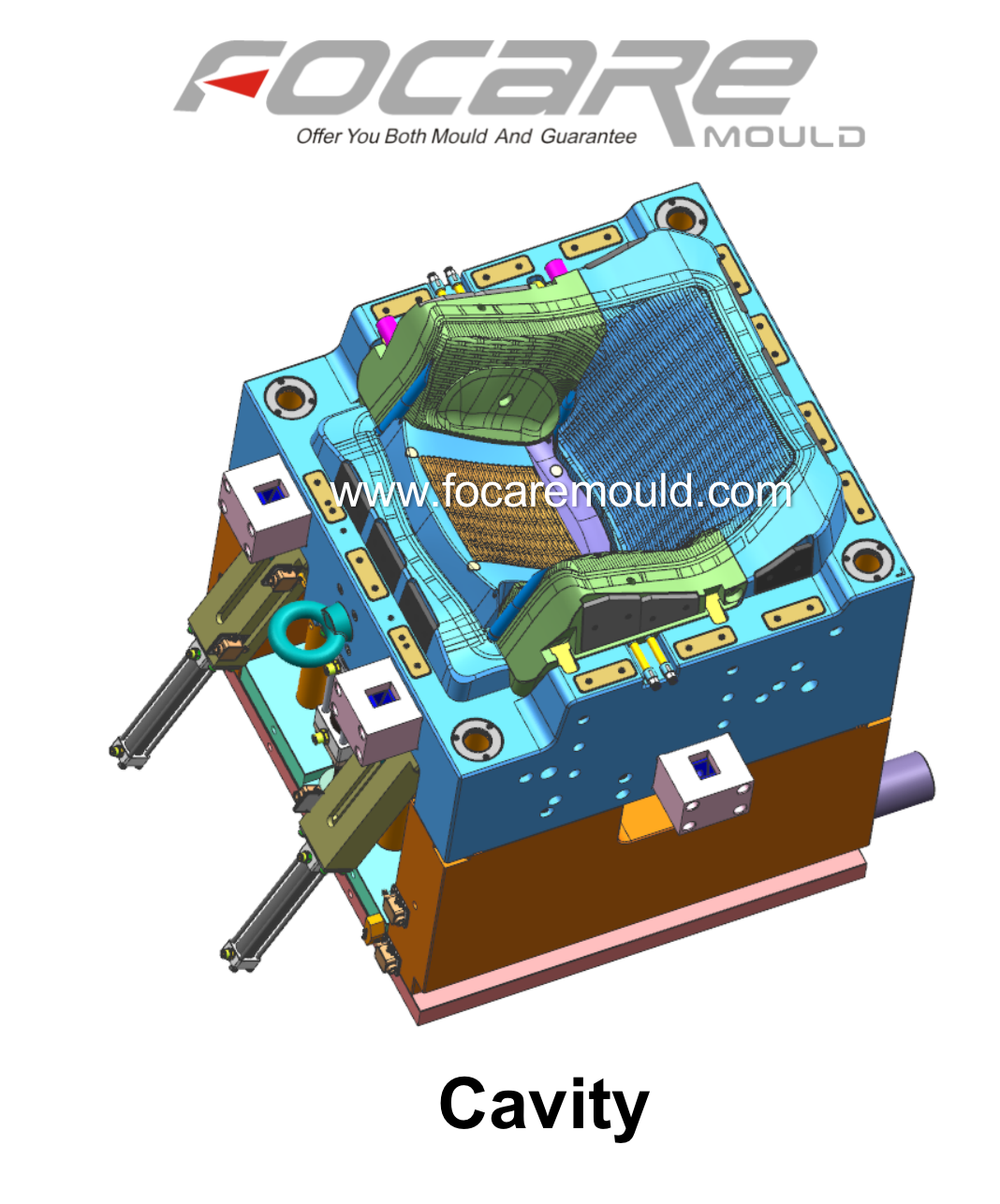

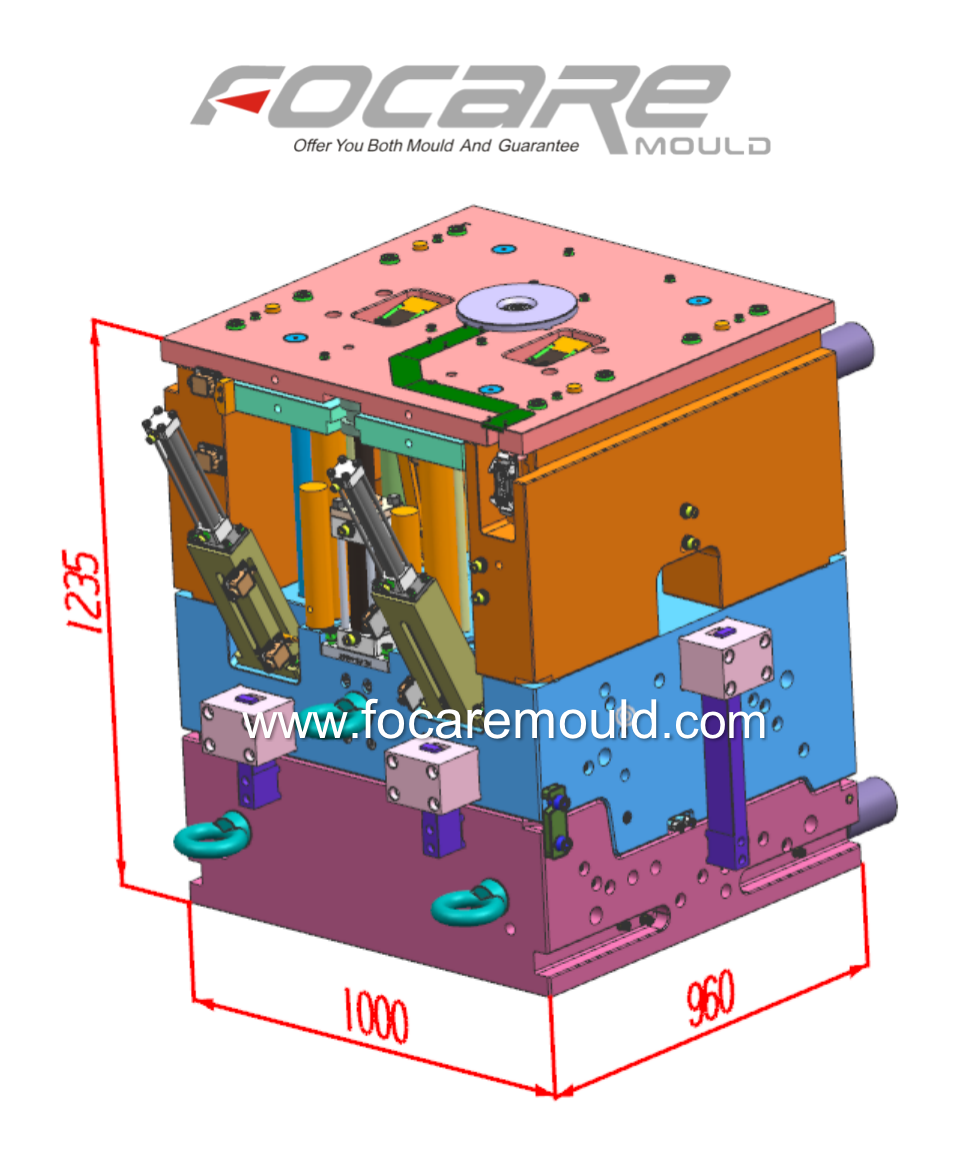

Cavities : 1

Sprue: 1 tip Hot Runner big gate

Mould size: 1000*960*1235mm

Mould weight: 7.9T

The plastic rattan chair biggest selling point is its appearance, which is exactly like a bamboo woven chair. However, the plastic rattan chair can improve the biggest weakness of bamboo chair: useful life.

The bamboo woven chair is easy to break that has to be replaced within years, also the broken bamboo is likely to scratch customers.

The size of plastic rattan chair is 63X53X53mm and the weight is 2.5kg.

It is big but light, and is durable, strong, easy to clean, beautiful, and colorful.

It is necessary to take every detail as careful as you can to perfectly manufacture a rattan chair plastic injection mould.

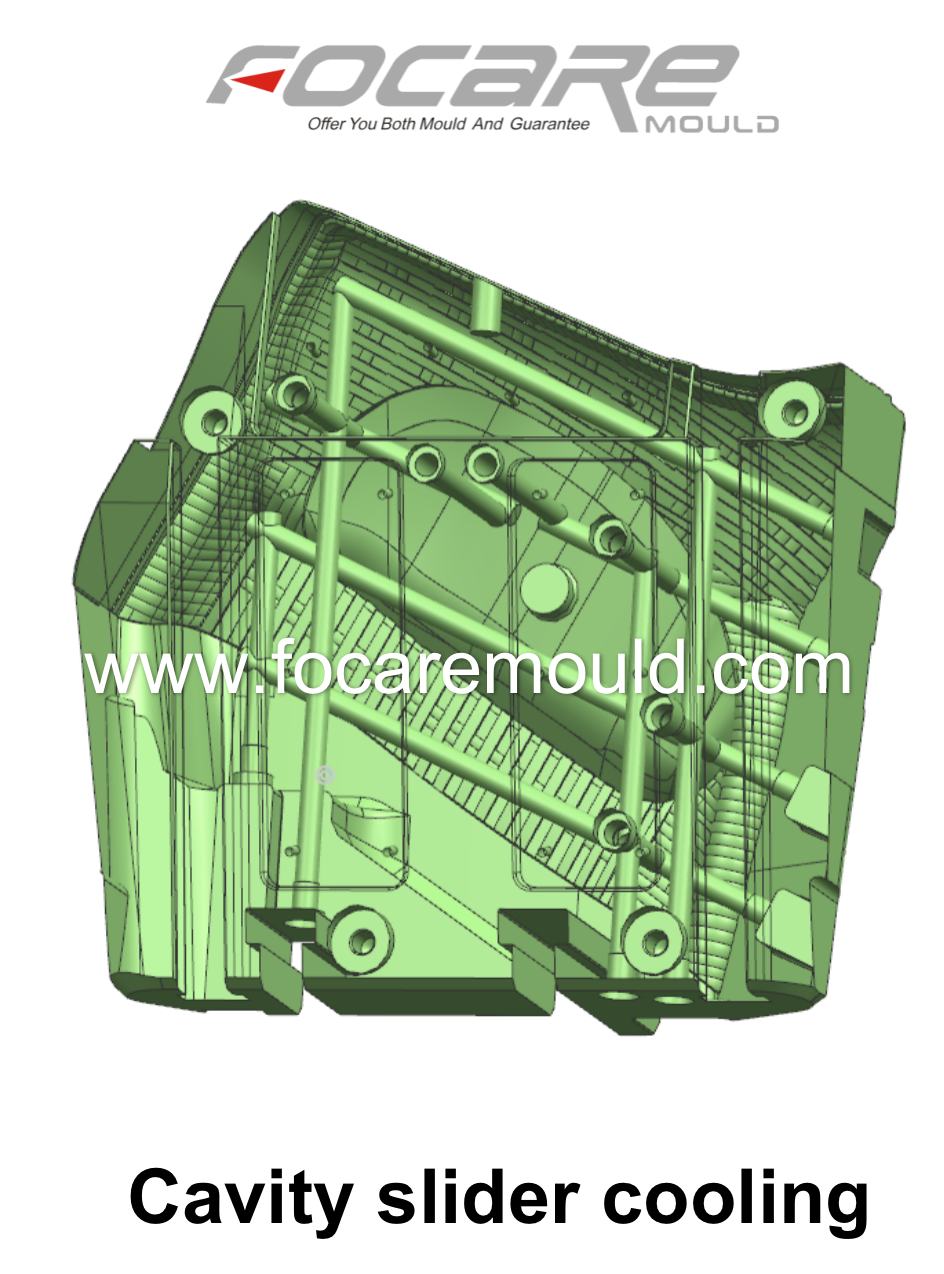

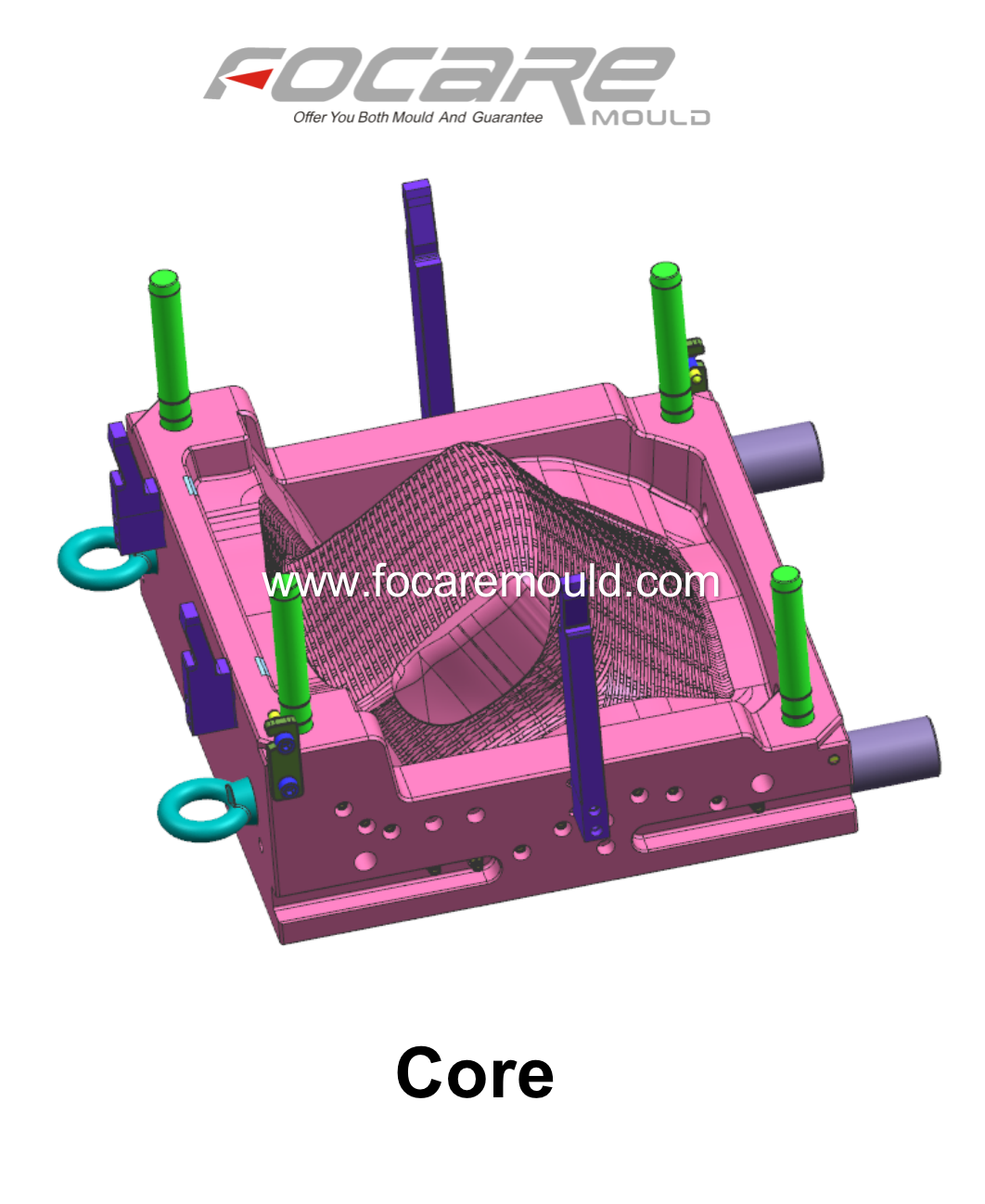

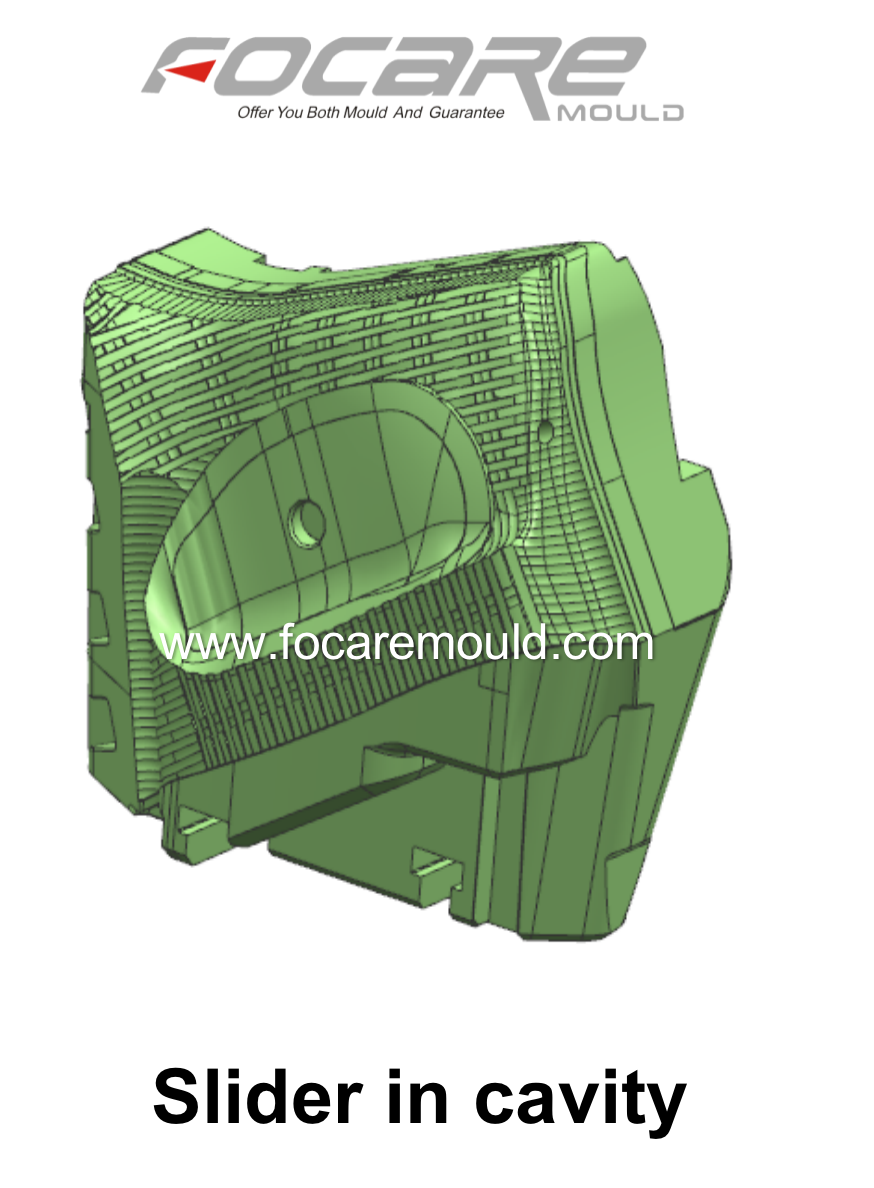

In order to make the clear rattan texture on chair appearance, it is necessary to design sliders which mold will be more complicate.

That’s said, the chair could not be ejected out from cavity directly, the sliders shall be move out first after mold opening, then ejecting out the chair from cavity after sliders being moved out.

Then, sliders are moved in before mold closing for making next shot.

Meanwhile, there will be limit switch to check if the stroke of slider cylinder is moved to safe position and protect the sliders before ejecting movement and mold closing.

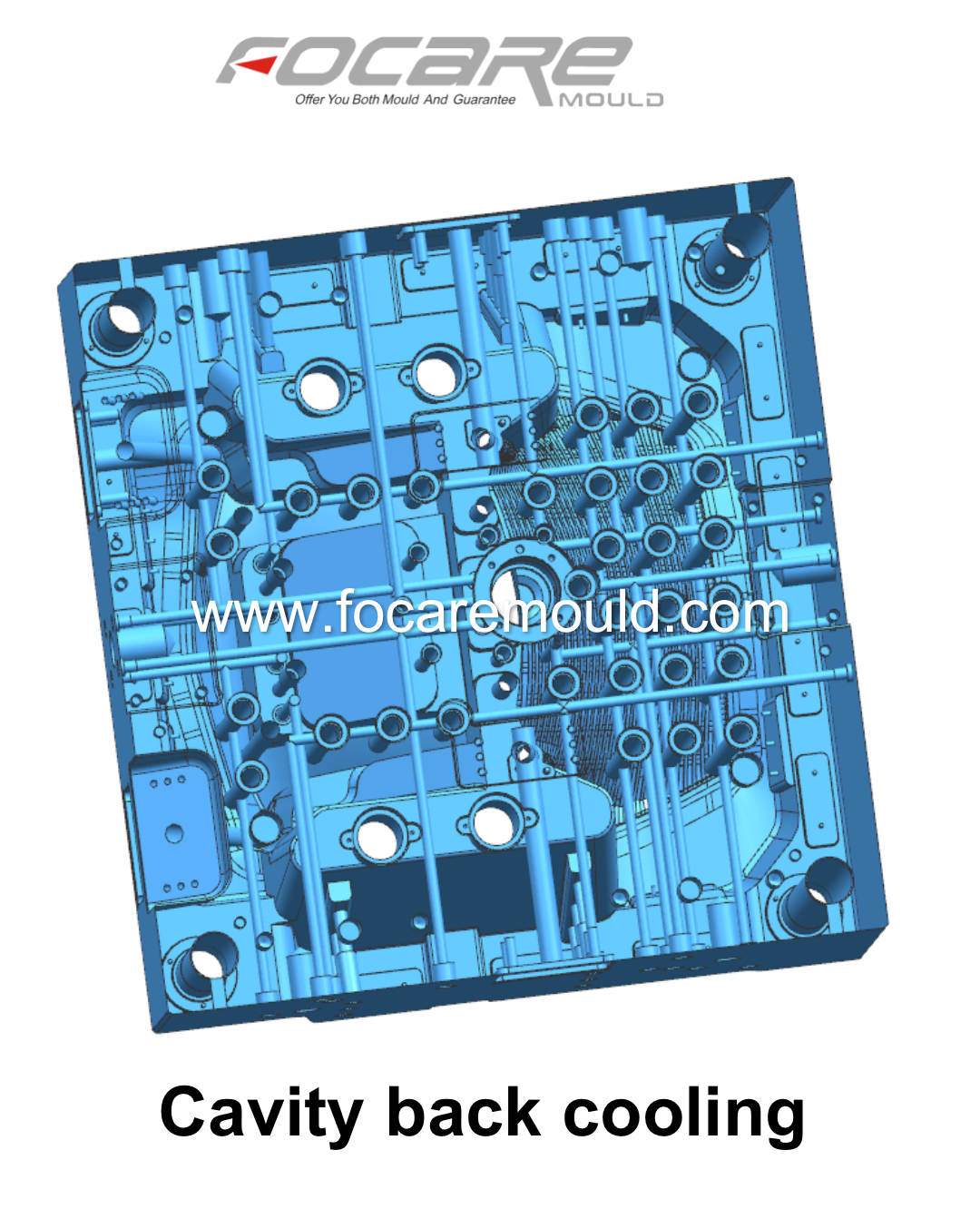

For the rattan chair plastic injection mould, Focare Mould, we apply 1 tip hot runner big gate and made the injection gate outside the chair, which means the eject system and inject system is designed on the same side.

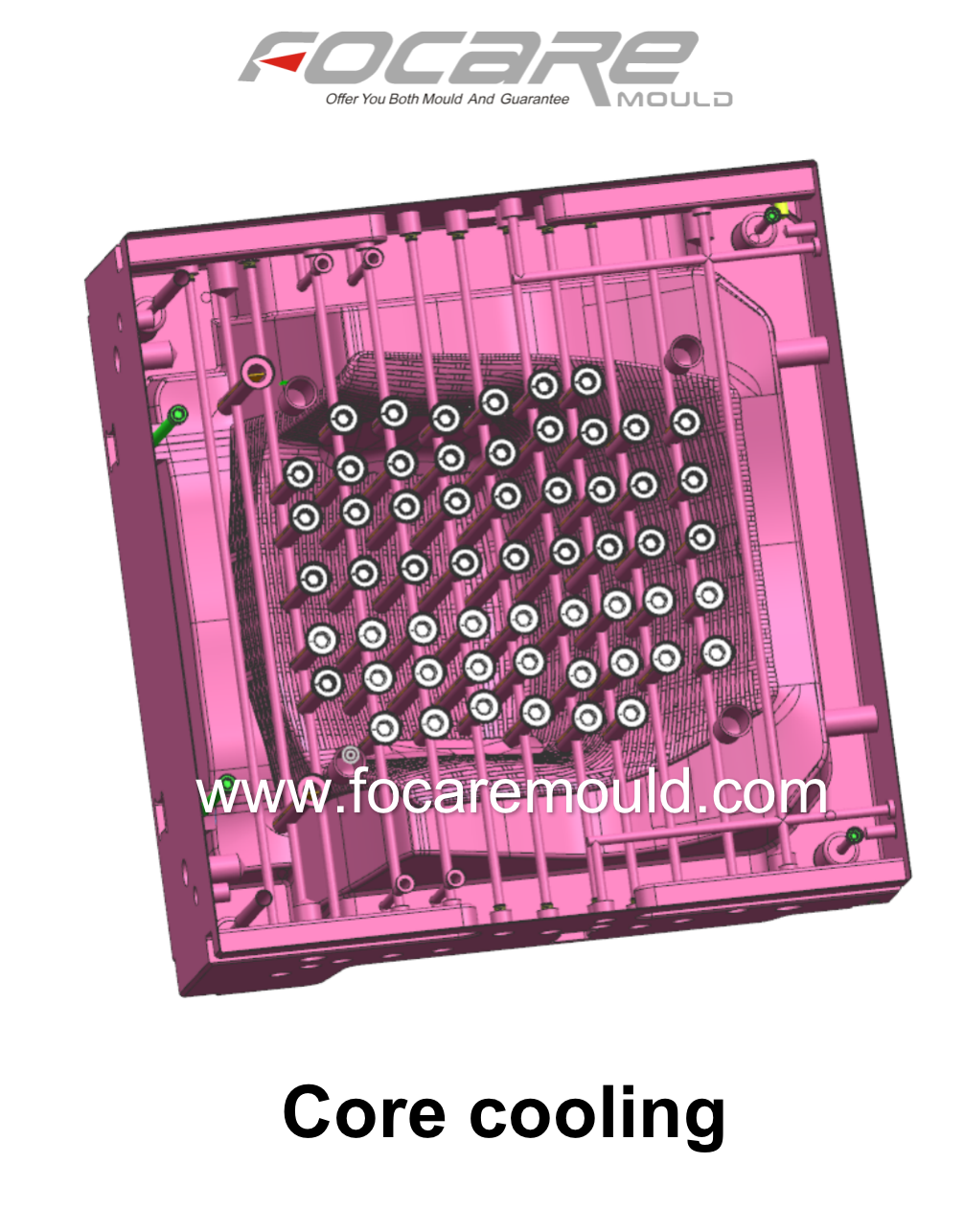

We design 4 ejector blocks, 6 hydraulic cylinders on the middle and four sides for better ejection, easier replacement.

To completely achieve the bamboo-like appearance and process the complicated mould structure, we make the mould precision within 0.02mm.

With the highest precision on every detail, we can insure the quality of both products and moulds.

Having made thousands of moulds, Focare Mould, we are a professional, experienced plastic injection mould maker.

Please contact us for more information and you will know that selecting Focare Mould as your mould maker is definitely worthy and satisfactory.