- Home

- >

- Products

- >

- Household Mold

- >

- Plastic storage toolbox mold

Plastic storage toolbox mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Choosing Focare Mould means opting for a seamless blend of innovation, reliability, and efficiency. As a prominent China mold maker, we take pride in delivering solutions that drive success for our clients in the plastic manufacturing industry.

If you’re looking for a dependable partner to create high-quality plastic injection molds for storage toolboxes, look no further than Focare Mould. Contact us today to discuss your project and experience the excellence we bring to the world of mold making.

Plastic Storage Toolbox Mold: Precision Craftsmanship by Focare Mould

In today’s fast-paced world, the demand for high-quality, durable plastic storage toolboxes is at an all-time high. These versatile products are widely used in homes, workshops, and industrial settings for organizing and storing tools and accessories. Behind every robust and functional toolbox lies the artistry and precision of an exceptional plastic injection mold.

At Focare Mould, a leading China mold maker, we specialize in crafting top-tier molds for plastic storage toolboxes. With years of expertise and state-of-the-art technology, our molds guarantee durability, precision, and efficiency in production.

Why Choose Focare Mould for Plastic Storage Toolbox Molds?

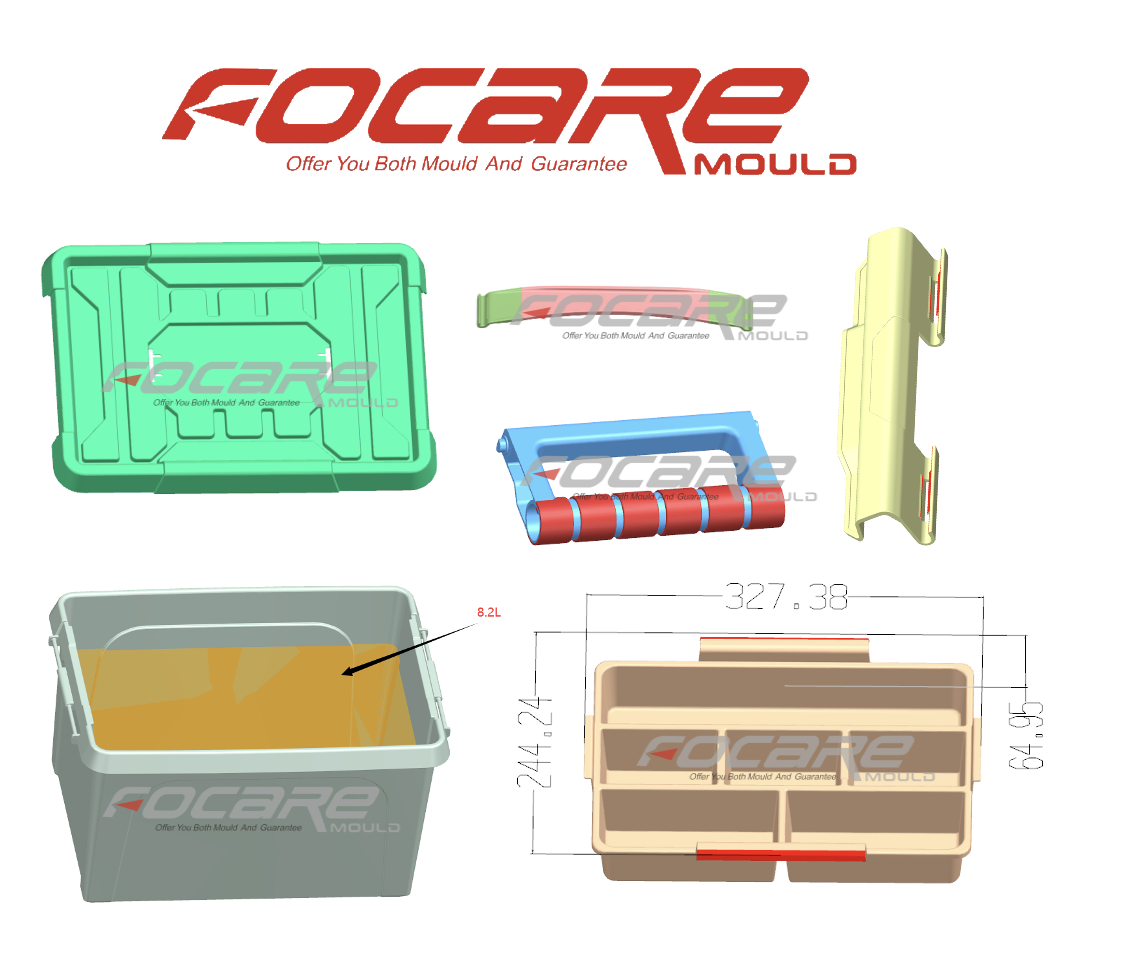

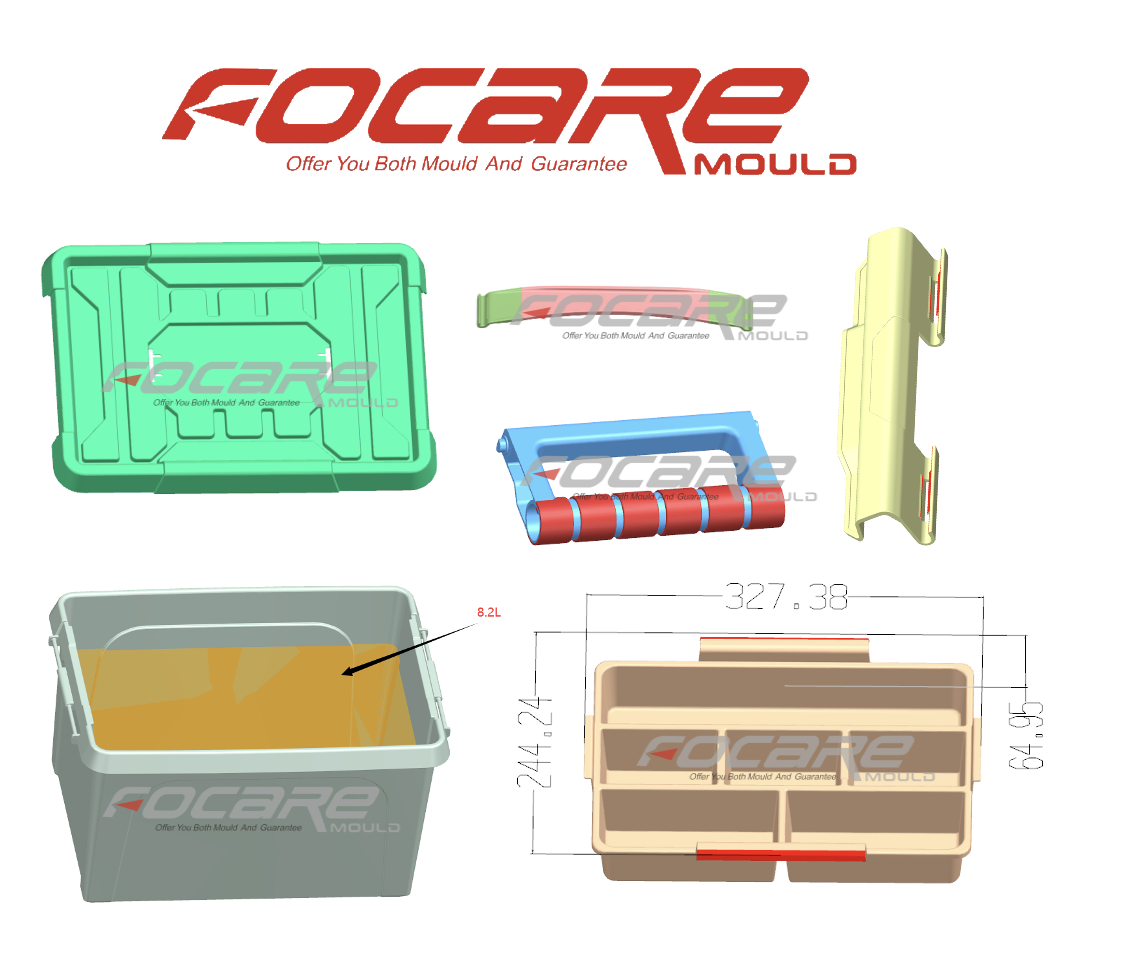

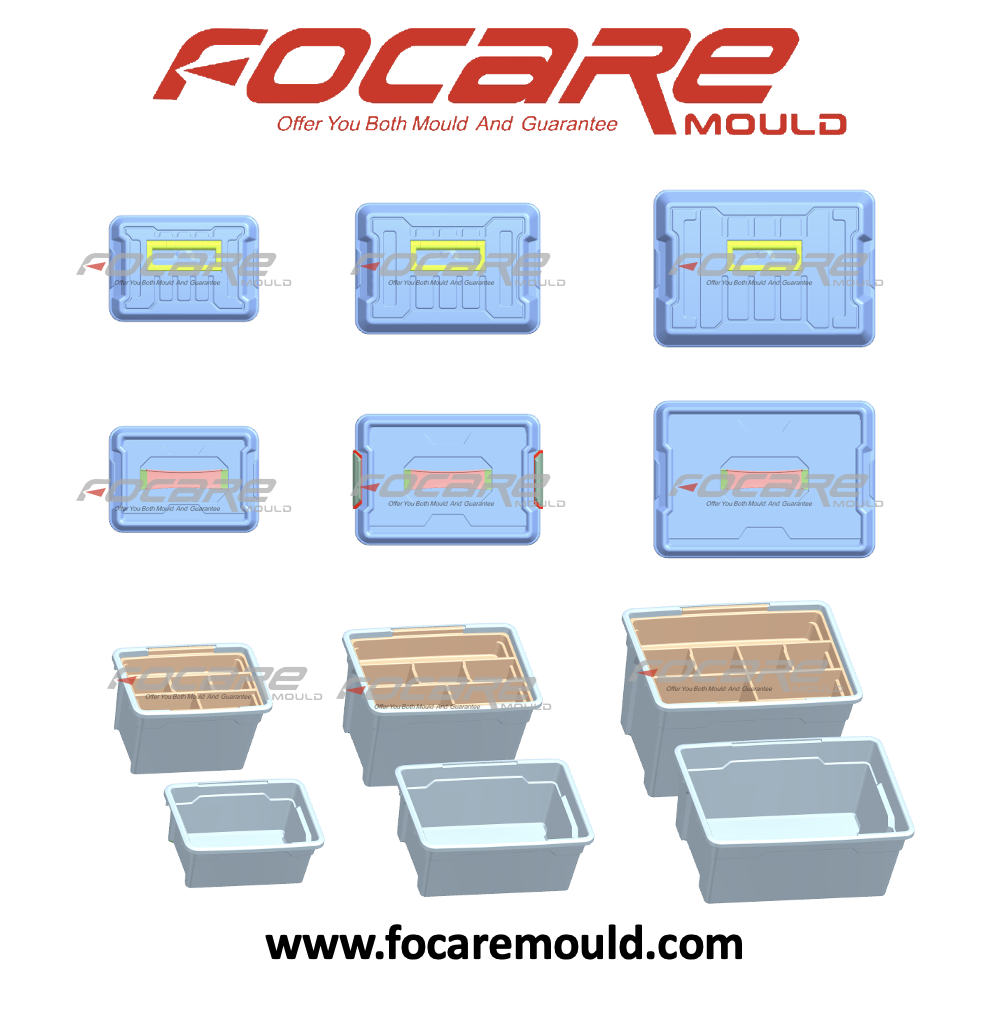

Tailored Designs for Diverse Needs:Each client has unique requirements for their toolbox designs, whether it’s specific dimensions, compartment layouts, or handle styles. At Focare Mould, we prioritize customization, ensuring the mold matches your exact specifications.

Precision Engineering:Our team leverages advanced CAD/CAM systems and precision machining tools to produce molds with exceptional accuracy. This ensures that the final plastic injection mold delivers products with consistent quality and flawless detailing.

Durability and Longevity:A mold is a significant investment, and its longevity is critical for maximizing ROI. We use high-grade steel and superior surface treatments to ensure that our molds withstand the rigors of high-volume production.

Cost Efficiency:As a trusted China mold maker, Focare Mould offers competitive pricing without compromising on quality. Our streamlined processes and efficient manufacturing techniques allow us to deliver top-notch molds within your budget.

Features of Our Plastic Storage Toolbox Molds

Multi-Cavity Options: Accelerate production with molds designed for multiple cavities.

Smooth Ejection Systems: Ensure easy removal of finished products without damaging the toolbox structure.

Customizable Textures: From matte to glossy finishes, our molds cater to varied aesthetic preferences.

Ergonomic Designs: Optimize user comfort with molds that create ergonomic handles and practical layouts.

The Plastic Injection Mold Process

The journey of creating a sturdy and reliable plastic storage toolbox starts with the perfect mold. At Focare Mould, the process includes:

Conceptualization and Design: Collaborating with clients to draft the ideal toolbox design.

Prototyping: Developing prototypes to test functionality and design feasibility.

Mold Manufacturing: Employing high-precision CNC machines to produce the mold.

Testing and Validation: Conducting rigorous trials to ensure the mold’s performance aligns with client expectations.

Partner with Focare Mould

Choosing Focare Mould means opting for a seamless blend of innovation, reliability, and efficiency. As a prominent China mold maker, we take pride in delivering solutions that drive success for our clients in the plastic manufacturing industry.

If you’re looking for a dependable partner to create high-quality plastic injection molds for storage toolboxes, look no further than Focare Mould. Contact us today to discuss your project and experience the excellence we bring to the world of mold making.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services