Plastic Cap of Liquor Bottle Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Plastic liquor caps are different from the ones we usually use. They are not sealed by threads or barbs like plastic caps of mineral water bottles, but by oak plugs. However, the oak plugs may cause decay or cracking after long-term and long-distance transportation or weather, plastic caps are needed to keep them sealed and protect oak plugs.

Plastic bottle caps play an important role in liquor packaging, daily necessities, and other packaging containers. It not only bears the basic functional responsibility of sealing and isolation, but also shoulders the responsibility of foiling the appearance of the whole packaging style. The structure design of plastic bottle cap should take into account not only production but also cost. At the same time, it should perfect the appearance concept in front of consumers

Plastic liquor caps are different from the ones we usually use. They are not sealed by threads or barbs like plastic caps of mineral water bottles, but by oak plugs. However, the oak plugs may cause decay or cracking after long-term and long-distance transportation or weather, plastic caps are needed to keep them sealed and protect oak plugs.

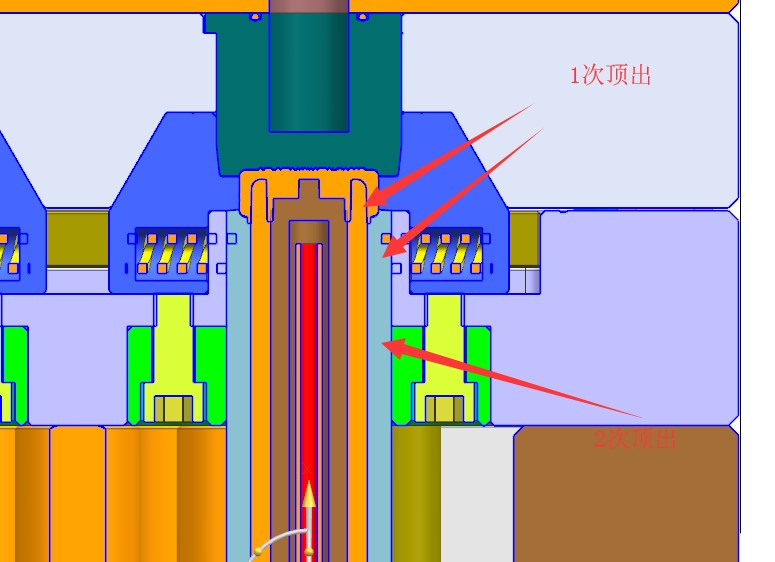

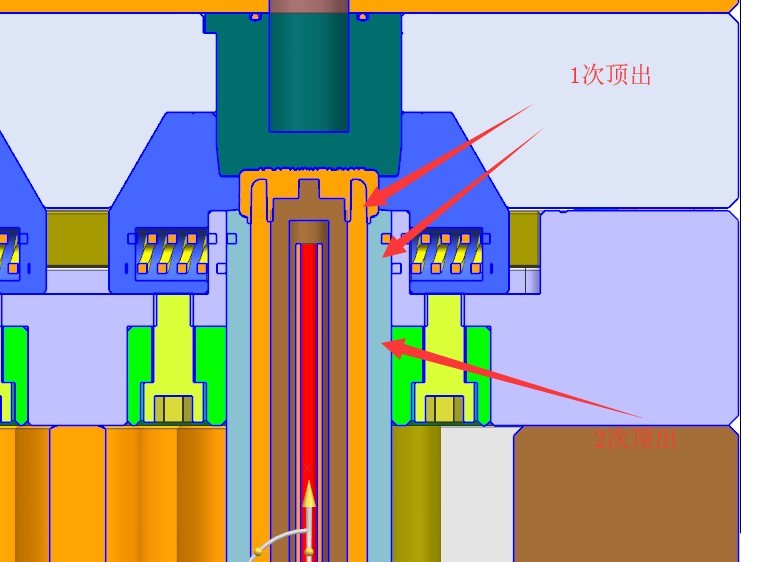

In the mould design, we designed a set of delayed ejection structure for the text and pattern on top of cap because the product is still packaged on the fittings at the first ejection, we also need the external pushing tube to continue the second ejection to ensure that the appearance of the product is not harmed.

Focare Mould is an experienced two-color injection mold maker; we have our own design group, skilled mold workers and technical mold testing workers. Even though you don’t have any experience in two-color injection molding area, just give us your ideal, we can design the products, make the molds and train your workers to operate the injection molding machine for you.