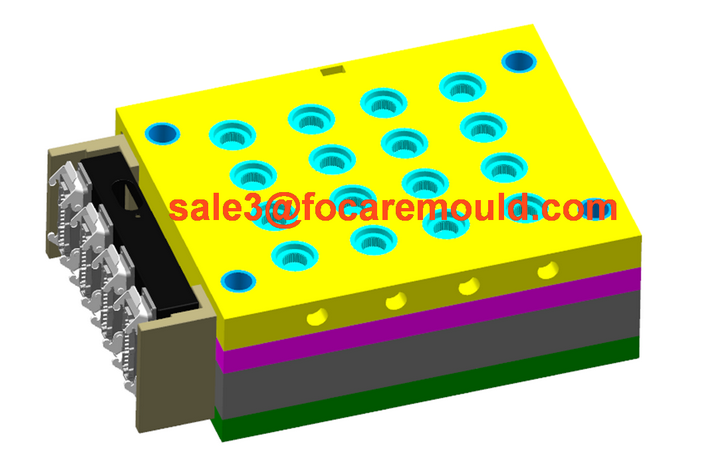

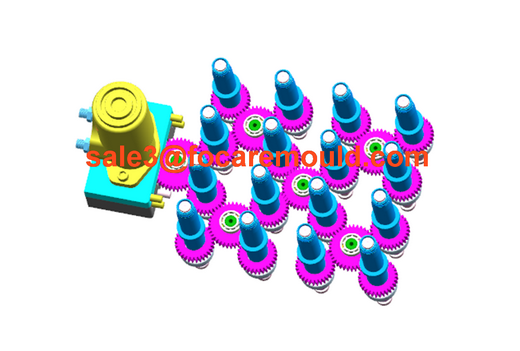

Plastic Cap Injection Mould with Unscrewing Device

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

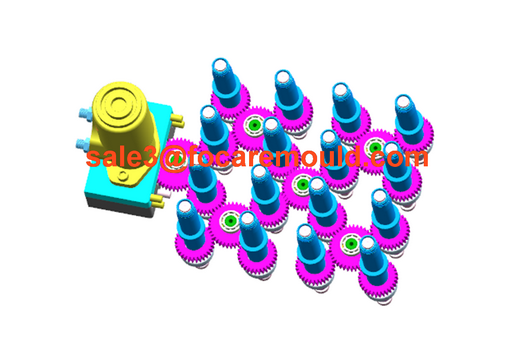

Principle of unscrewing device system:

The head of the motor is equipped with gears, which drive the chain, the chain drive the middle bearing, and the bearing gear drive the two big gears. The big gear is kneaded with the bearing gear of the product, and the inner screw of the product is pulled out by rotation.

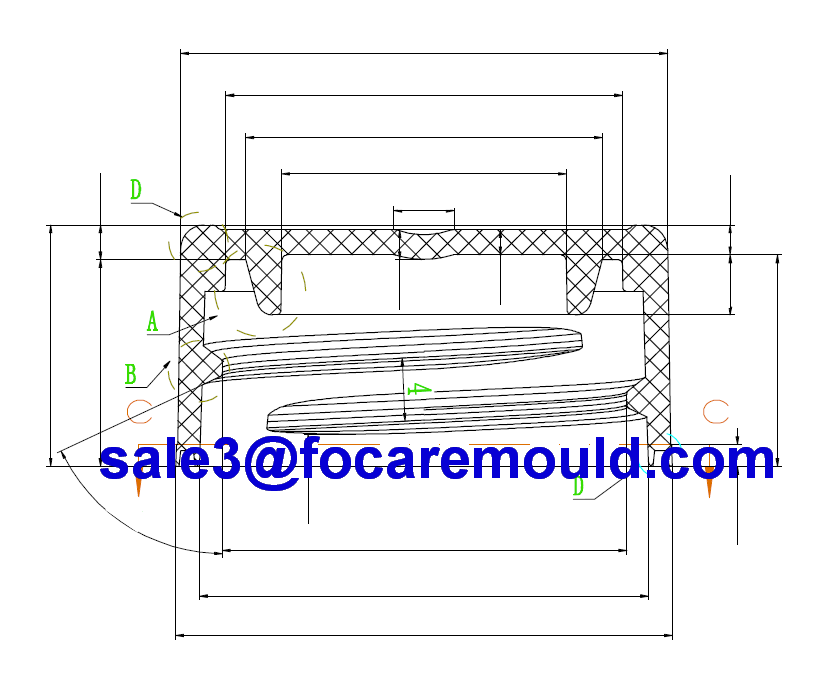

Nowadays, the most popular thread shapes of thermoplastic thread caps in the world are "maneuvering demoulding “and "forced demoulding ". These two designs have their own advantages and disadvantages, and their choice usually determines their final use.

In the process of injection moulding, there is unscrewing device system in the mould. This action can effectively protect the integrity of the cap screw. Therefore, the thread shape of the cap can be effectively controlled, and the cap wall will not tilt when rotating the thread of the upper shank of the bottle.

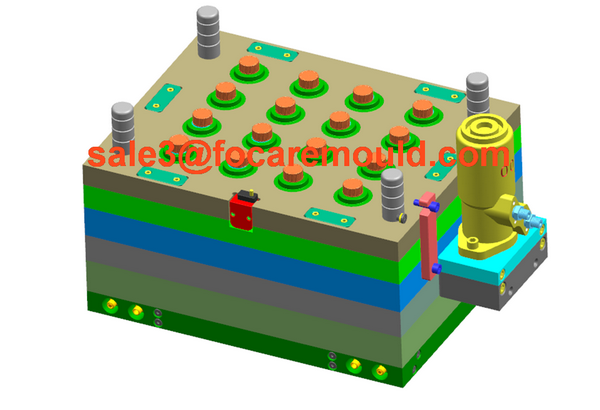

Power of unscrewing device system:

1. The power of the unscrewing device system can be driven by a motor. The head of the motor is equipped with a gear, which is driven by a chain.

2. The mounting position of the motor can be fixed on the upper side of the core.

Principle of unscrewing device system:

The head of the motor is equipped with gears, which drive the chain, the chain drive the middle bearing, and the bearing gear drive the two big gears. The big gear is kneaded with the bearing gear of the product, and the inner screw of the product is pulled out by rotation.

When designing bearings, attention should be paid to the design of keyway and gear alignment.

Because the thread of the screw can't effectively restrict the gasket of the bottle cap from falling off, so the screw cap is glued when the gasket is added.