- Home

- >

- Products

- >

- Household Mold

- >

- Plastic bucket injection mold

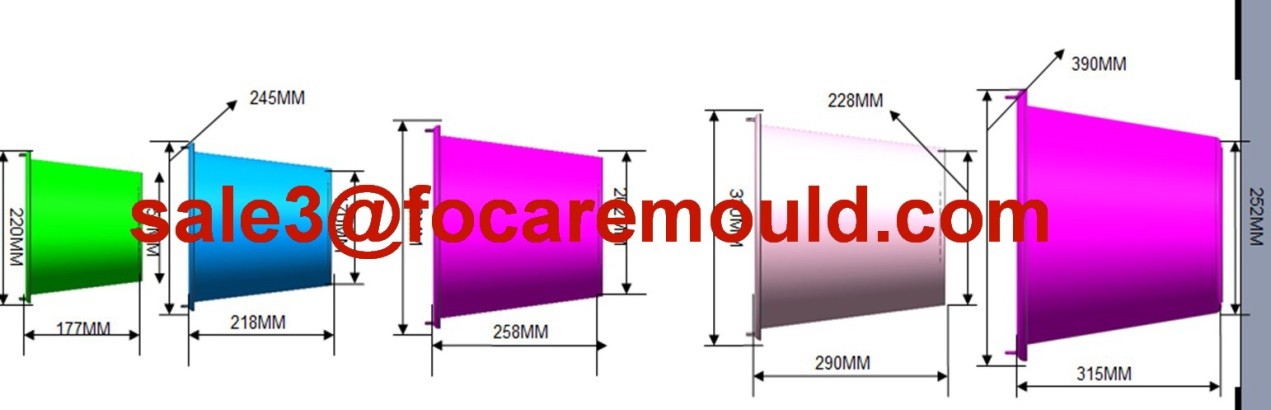

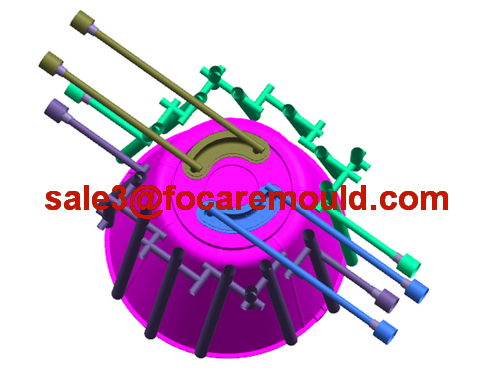

Plastic bucket injection mold

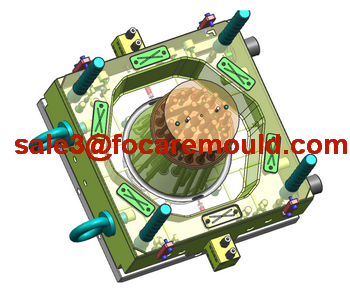

Normally, in order to optimize your products, many people choice to use IML (in mold labeling) to have different kinds of products with only one plastic mold. But if you do not have the budget to purchase the IML system (normally one robot, one static generator, and labels), you can also consider to use texture on the surface of the plastic buckets. The texture can be the big logo of your company, the signs of your National culture or any drawings which can catch consumers’ eyes.

Plastic buckets play an important role in our daily life. Whether it's the poor or the rich, there are plastic buckets in every family. Because plastic buckets are not only cheap for the price but also very useful. Plastic buckets are light and stackable. They won’t occupy too much space when you don’t use them. You can use them for storing foods or holding water. It is helpful when we would like to clean the house, too. With the plastic buckets, we can save our time to wash rags and mops while we are cleaning.

Normally, in order to optimize your products, many people choice to use IML (in mold labeling) to have different kinds of products with only one plastic mold. But if you do not have the budget to purchase the IML system (normally one robot, one static generator, and labels), you can also consider to use texture on the surface of the plastic buckets. The texture can be the big logo of your company, the signs of your National culture or any drawings which can catch consumers’ eyes.

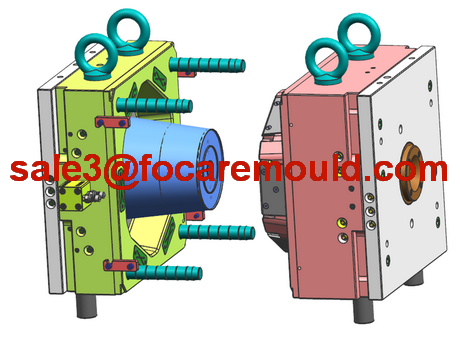

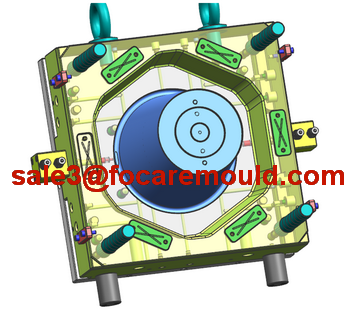

For the circle bucket molds, it is important to make sure the thickness of the bucket is identical. From an economic point of view, the ideal plastic wall thickness should be as thin as possible, because thin wall can save material and the production cost will be cheaper, but it must be considered whether it can be formed during injection. If the plastic wall is too thin, it will cause the problem that material cannot flow through filled shots. In addition, the thinner the plastic wall, the weaker its strength will be. Special consideration must be given to areas with strength requirements.

The wall thickness of the finished plastic buckets should depend on the needs of the product, the size of the product, whether it must withstand external forces, the strength of the product, whether it needs to be used as a support for other components, and whether the selected plastic material is reinforced and can be shaped ...etc.