- Home

- >

- Products

- >

- Medical Parts Mold

- >

- Petri Dish Plastic Injection Mould

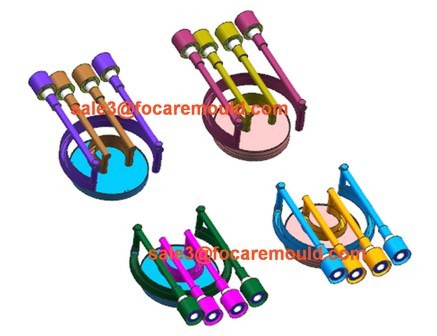

Petri Dish Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

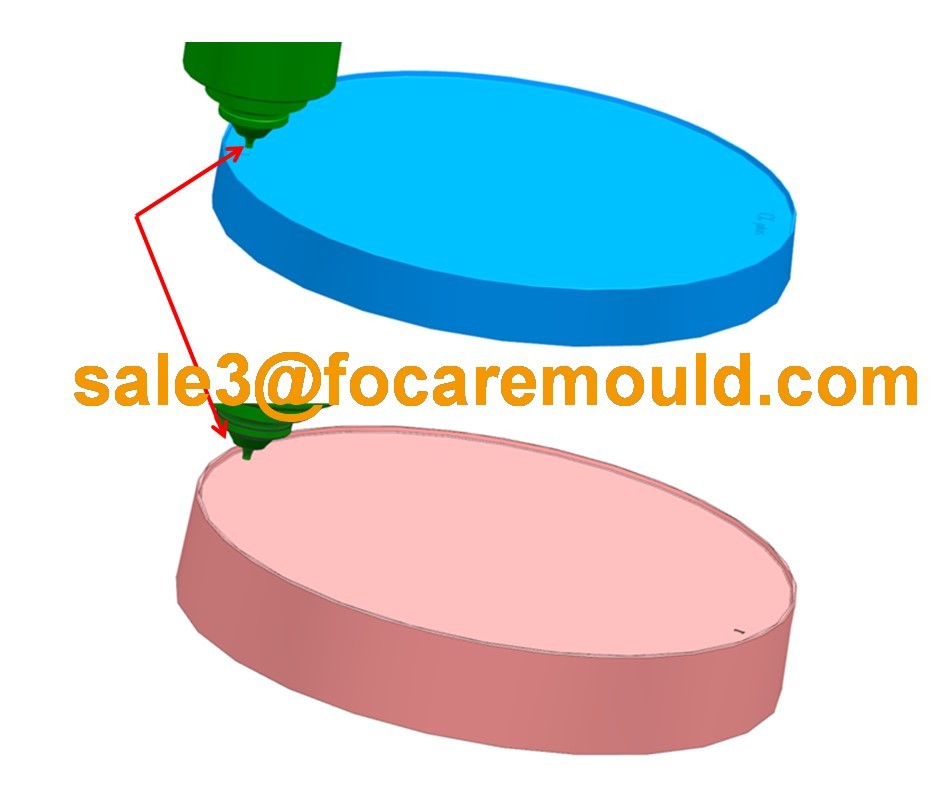

A Petri dish is a laboratory vessel for the cultivation of microorganisms or cells. It consists of a flat disc-shaped bottom and a cover, usually made of glass or plastic. There are basically two types of dish materials, mainly plastic and glass. Glass can be used for plant materials, microbial culture and animal cell wall culture. Plastic may be polystyrene material, which can be used for one time or multiple times. It is suitable for laboratory inoculation, scribing and bacteria separation. It can be used for the cultivation of plant materials.

A Petri dish is a laboratory vessel for the cultivation of microorganisms or cells. It consists of a flat disc-shaped bottom and a cover, usually made of glass or plastic. There are basically two types of dish materials, mainly plastic and glass. Glass can be used for plant materials, microbial culture and animal cell wall culture. Plastic may be polystyrene material, which can be used for one time or multiple times. It is suitable for laboratory inoculation, scribing and bacteria separation. It can be used for the cultivation of plant materials.

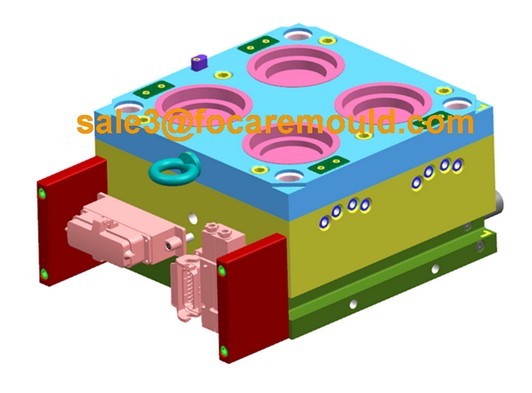

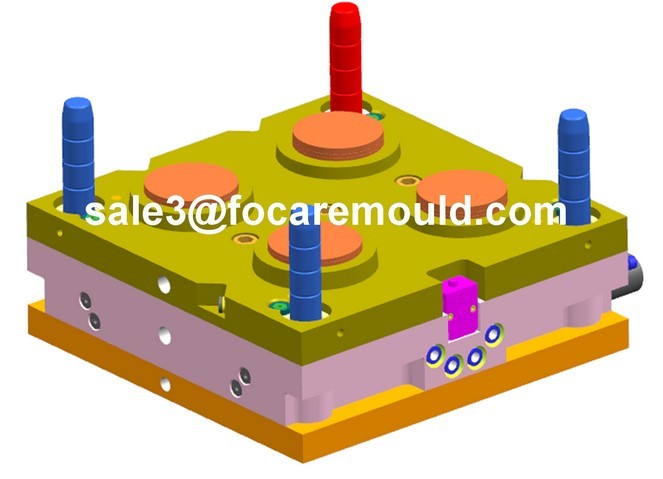

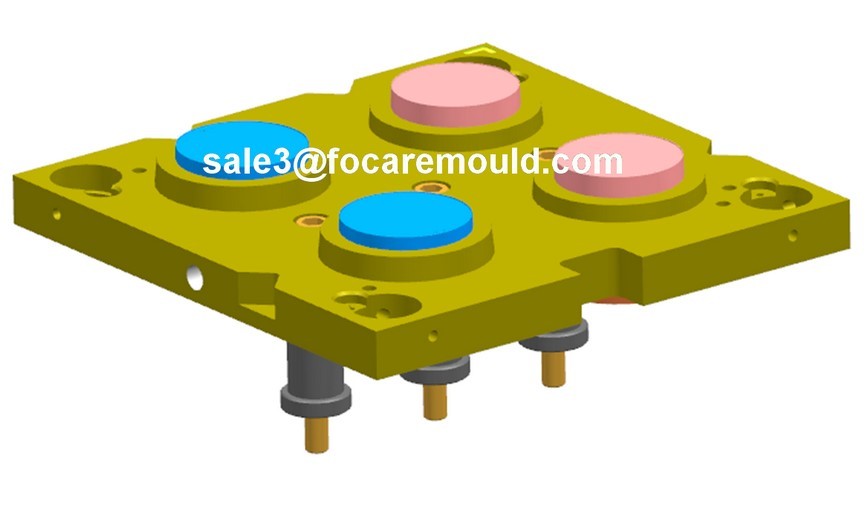

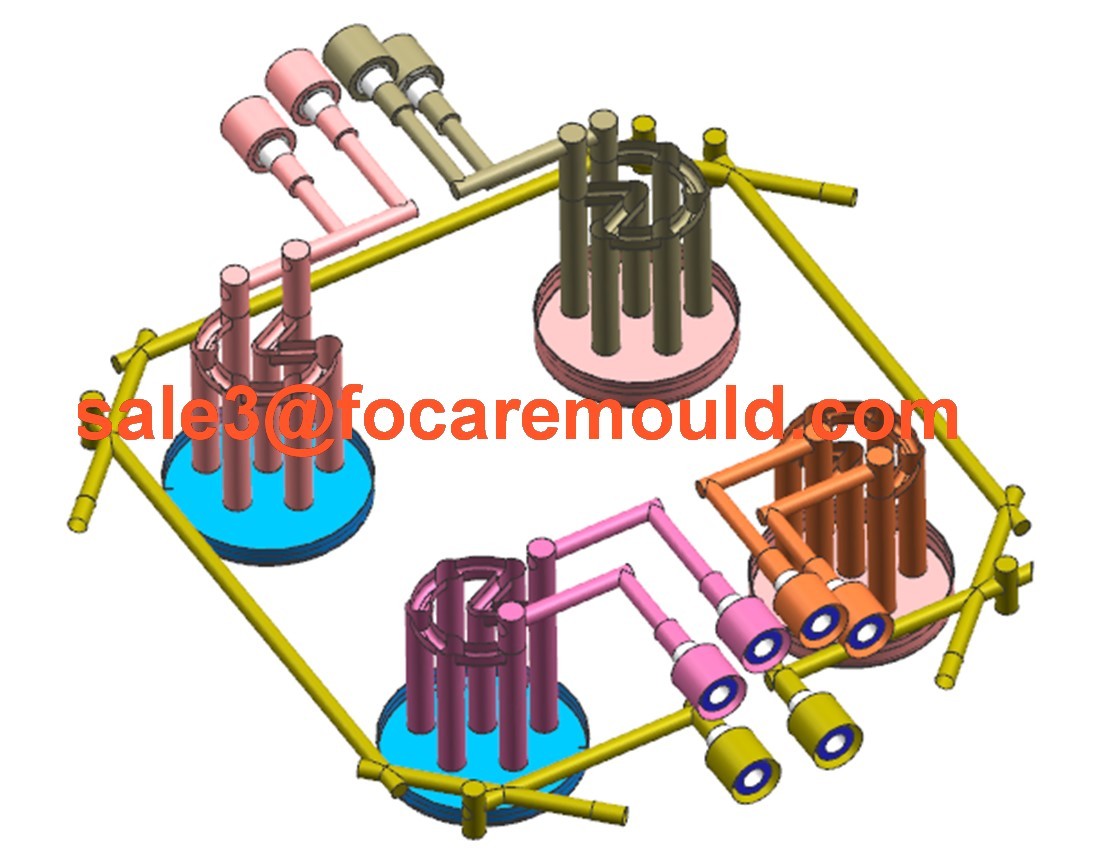

For the Petri dish mold, it is designed with valve gate of hot runner in order to get smooth and tiny injection point. The wall thickness of Petri Dish is thin, it is easy to control the even wall thickness of Petri Dish if mold is used valve gate hot runner system.

Moreover, the design of the cooling system is a complicated work, that is, to consider the cooling effect and cooling uniformity, and to consider the influence of the cooling system on the overall structure of the mold to determine the specific location and size of the cooling system. The cooling water system of common mold has slow cooling and poor quality of mold forming. The better the cooling effect of the mold, the higher the quality of the mold.

In order to solve the problem of the cooling system of the common mold, we adopt the efficient circulating water outlet mode, so that the cooling time of the mold can be shortened. Our mold adopts the way of circulating water to flow in every part of the mold, reducing the cooling time during injection molding, improving the production efficiency of products, and greatly reducing the production cost.