- Home

- >

- Products

- >

- Kitchenware Mold

- >

- Two Color Plastic Plate / Serving Tray Mold

- >

- Durable Double Color Plastic Egg Tray

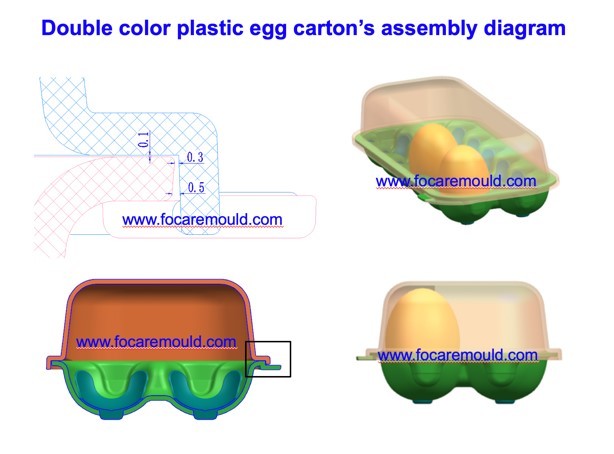

Durable Double Color Plastic Egg Tray

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

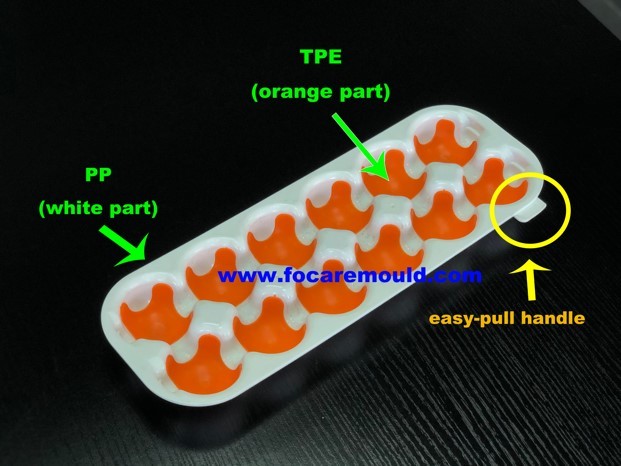

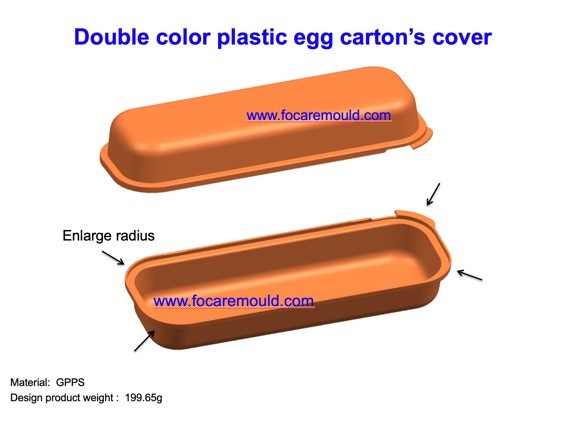

This double color plastic egg tray is made out of PP (white body) +TPE (orange bottom) by the two-color rotary injection mould, and the cover is made out of GPPS which is transparent and stronger, using TPE as bottom in order to keep eggs out of crushing, what’s more, we put four anti-slip pads each corner under the bottom to keep it away from slipping on the table or the fridge.

Nowadays, egg carton we see in the market, are more likely made by paper, plastic is still not that common to be seen, even though there are, they are just made in single-color.

But now we made it in plastic, its dvantages are as below:

· SAFE STORAGE: This double component egg tray fits 12 eggs in individual compartments, instead of putting eggs in a flimsy paper egg carton, putting them in plastic one can eliminates the risk of eggs crushing, and with the cover to keep your eggs fresh and secure.

· PORTABLE: The tray body has a small easy-pull handle to make it simple to move on and off shelves in your fridge, just grab and go, and the transparent cover makes it easy to see the quantity inside and quickly grab the right amount you need.

· DURABL: It could be reused for environment protection and waste deduction.

This double color plastic egg tray is made out of PP (white body) +TPE (orange bottom) by the two-color rotary injection mould, and the cover is made out of GPPS which is transparent and stronger, using TPE as bottom in order to keep eggs out of crushing, what’s more, we put four anti-slip pads each corner under the bottom to keep it away from slipping on the table or the fridge.

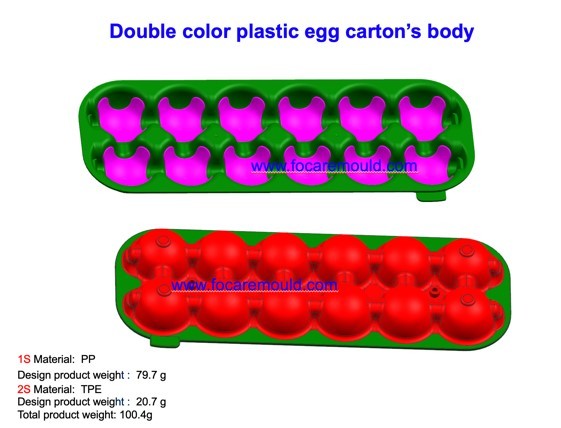

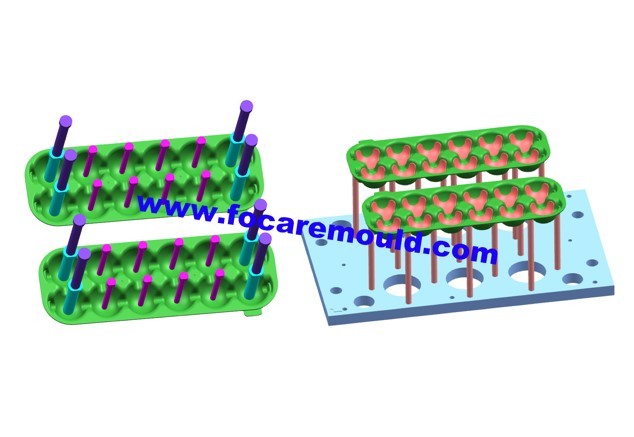

This two-component plastic egg tray is made by double color rotary mold with 2+2 cavities which could be produced by 280 tons two-color injection moulding machine. The PP base is made by 1st injection, then rotate the mold 180 degree to 2nd position, then make TPE injection to cover on PP base. The advantage of rotary mold is to reduce the shrinkage variance between PP and TPE in shorten time, and easier to get the best quality of two-component plastic products.