- Home

- >

- Products

- >

- Kitchenware Mold

- >

- Two Color Foldable Strainer Colander Mold

- >

- Double Color Lotus Collapsible Strainer Plastic Injection Mould

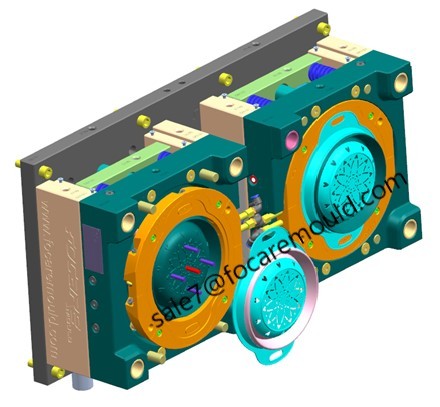

Double Color Lotus Collapsible Strainer Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Focare Mould demonstrates the capability of design and the power on double color molds. The new two-color collapsible strainer is so high quality. The product has fine appearance, delicate texture, and good feeling when holding and collapsing.

Focare Mould demonstrates the capability of design and the power on double color molds. The new two-color collapsible strainer is so high quality. The product has fine appearance, delicate texture, and good feeling when holding and collapsing.

To manufacture excellent plastic injection moulds, Focare Mould, our moulds will pass four challenges:

1. Product design: The designer not only needs to take the appearance and function into accounts, but also the details of assembly between products, products inclination that affect the mould eject system, and structures whether various mould designs can achieve or not.

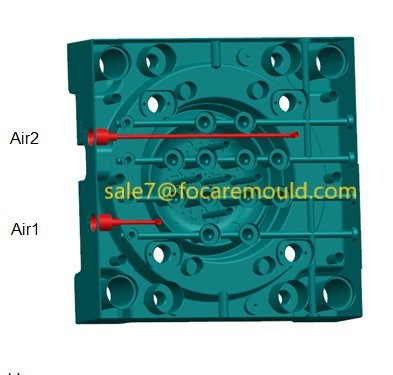

2. Mould design: In order to make every production smooth and economical. There are some basic issues that need excessive considerations, including shrinkage of products and between materials, injection position and runner design for balanced injection, injection gate for product appearance, cooling system for reducing cycle time and preventing deformation, exhaust and eject system for every successful ejection.

3. Mould process and assembly: A perfect product needs to have smooth injection gate, parting line, ejection mark, no flash, no air trap, and no deformation. Even you have the best mould design in the world, it will never be able to produce a perfect product without the precision of every mold parts. To ensure the accuracy of mould, we adopt the imported steel, high accuracy CNC machines, and technical mould makers to complete a plastic injection mould, especially double color injection moulds.

4. Mould testing: The last challenge for a mould. Only when the product is perfect and the mould function is well, the mould is successful. However, every injection is various, and a little adjustment on the parameter can make a big difference between products, which means the operators is critical.

To manufacture a mould takes lots of time and countless efforts, which means experience plays a vital role. Focare Mould, we make our every mould step by step with patient and honest. For years of insist, we build strong foundation and accumulate capabilities. Being an expert in making high-end moulds, we don’t offer the cheapest price for a normal mould, however, we ensure to provide a good price for moulds that with highest CP value. Contact us for more details, you will know the excellence of Focare’s Mould.