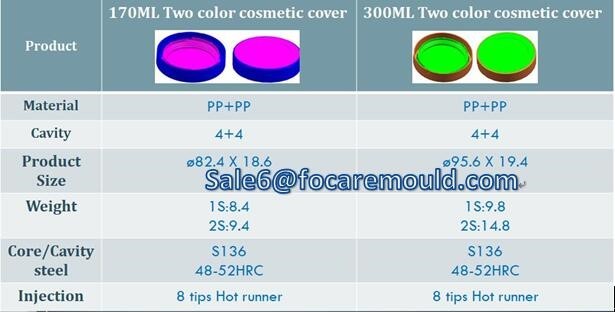

Double Color Cosmetic Cap Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

This double color cosmetic cap is not only two colors, but also the caps have to be demoulded out from mold by unscrew device instead of conventional forced ejection. The mold structure is more complicate than other double color mold and mold dimension is bigger. Moreover, the steel of unscrew device shall be high-end quality with heat treatment in order to avoid wearing and tearing in short time of movement.

According to the trend of the modern market in the cosmetic of fashion, many competitors continue to develop new beauty products, which is to be competitive in the market. I believe that in addition to allowing consumers to buy not only the brand reputation of cosmetics or the efficacy, evaluation, another reason for consumers to spend money must be, product appearance. The progress of the times has been from the packaging of monochrome products to the packaging of Multi-color products. Not only can the appearance of the products capture the eyes of consumers, but also increase the color of their own brands.

The design of double color product affects complexity of the mold structure. Some products design may look simple and easy, but they are required a lot of complicated double color mold structure design to get high-end and acceptable quality.

This double color cosmetic cap is not only two colors, but also the caps have to be demoulded out from mold by unscrew device instead of conventional forced ejection. The mold structure is more complicate than other double color mold and mold dimension is bigger. Moreover, the steel of unscrew device shall be high-end quality with heat treatment in order to avoid wearing and tearing in short time of movement.

With regard to the plastic cap with thread, there are two ways on manufacturing the mold.

First, the plastic cap is ejected by forced demoulding, it is easier design for making ejecting system. The plastic injection mold is designed twice ejector to demould plastic cap from cavities. However, this kind of forced demoulding design is easy to damage the thread of plastic cap if the cooling time is not enough, then it will cause the problem of assembly with bottle.

When the thread height of cap is high and plastic material is rigid, it is necessary to design gear system for ejecting caps from cavities. The structure of the gear system needs to design the arrangement of the gears, transmission gears, the central shaft with the gear system and the ejection system. We need to calculate how many turns of the gear to take off, and the length of the drive rack will pass or not. This design of gear system generally is called mechanical ejecting system. It necessary to have good experience on mold design to get precise position for ejecting caps from mold cavities. Meanwhile, gear ejecting system is moving parts which is easy to be worn and torn if the steel quality is not good and hardness is not enough. Hence, the steel of unscrew device shall be finished by heat treatment.