- Home

- >

- Products

- >

- Kitchenware Mold

- >

- Disposable Cutlery Mold

- >

- Disposable Cutlery Plastic Injection Mould

Disposable Cutlery Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

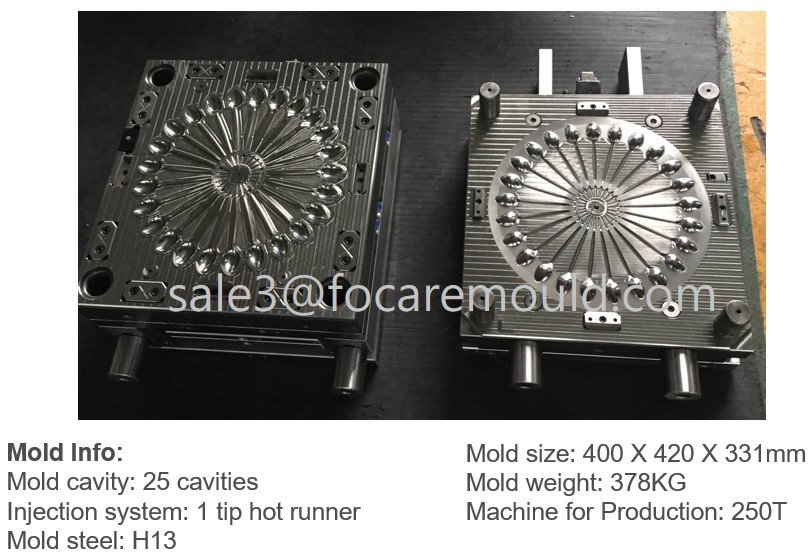

Due to the rapid economic development, there are more and more people choice take-away meals, and therefore the demand for disposable tableware is also growing. Generally, the material of disposable knife, fork, spoon is PP and PS. Because of the different material, the choice of mold steel will be different. Most of the steel of disposable knife, fork and spoon is made of quenched grade steel, such as H13, S136, 2344, 2316, etc.

Due to the rapid economic development, there are more and more people choice take-away meals, and therefore the demand for disposable tableware is also growing. Generally, the material of disposable knife, fork, spoon is PP and PS. Because of the different material, the choice of mold steel will be different. Most of the steel of disposable knife, fork and spoon is made of quenched grade steel, such as H13, S136, 2344, 2316, etc.

Because disposable cutlery is used only once, its characteristic is cheapness. To meet the requirement of cheapness, we must consider the production cost. First of all, the cutlery must be light, which means that the raw materials it needs are not much.

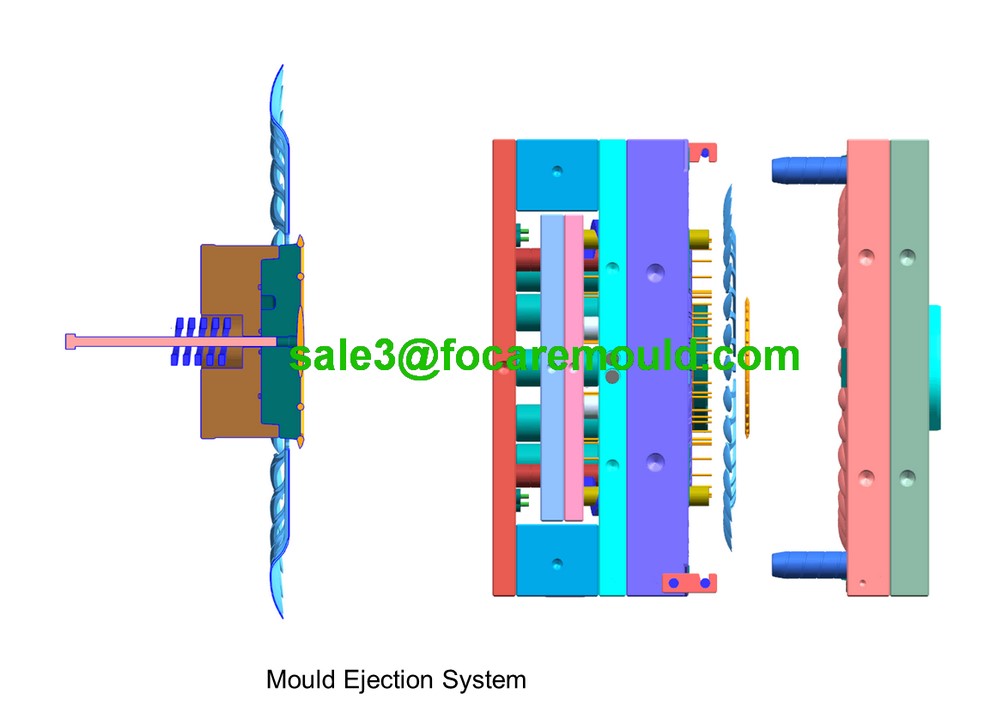

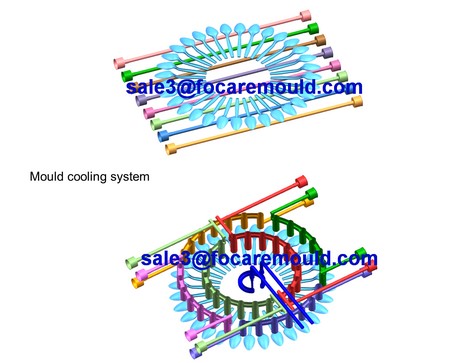

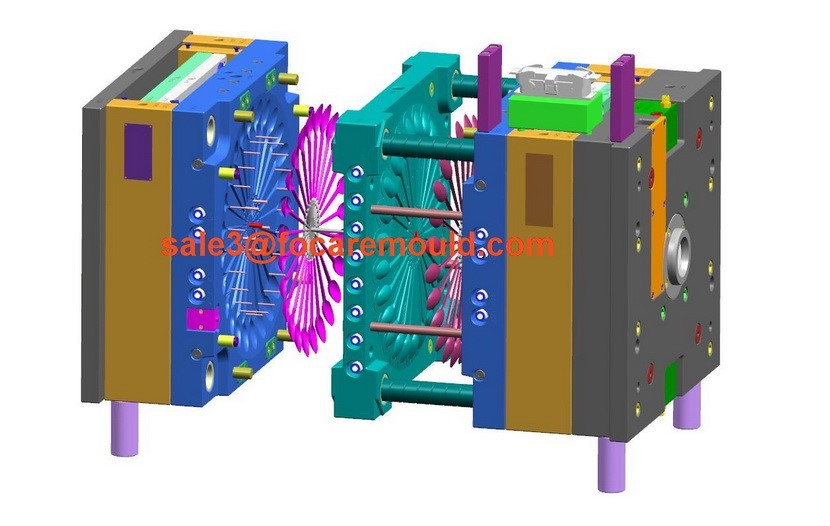

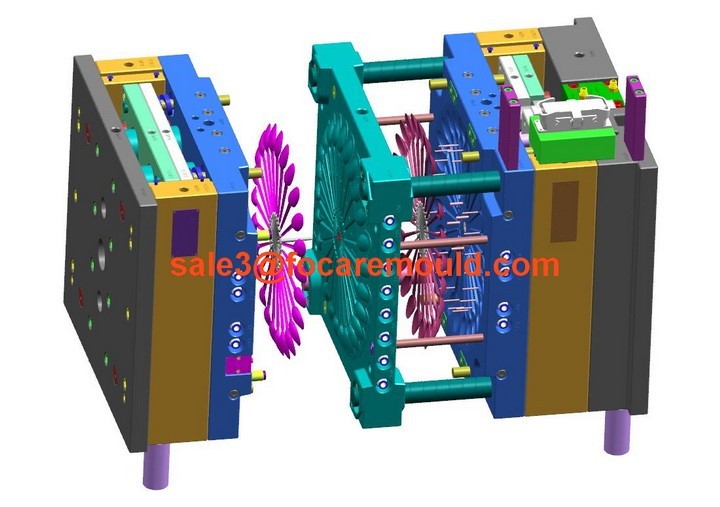

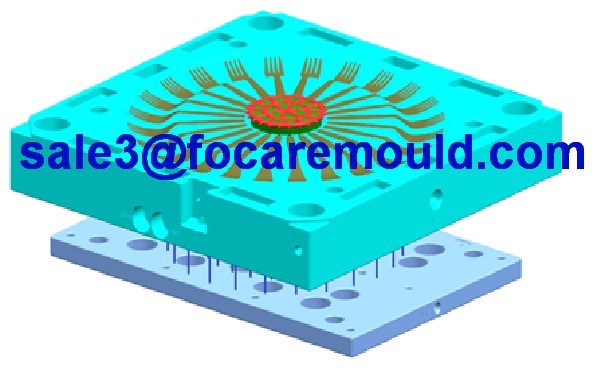

In addition, the finished products are arranged in a circular shape on the mold, which can save more steel. To save the production time, the mold needs very good cooling system to shorten the cycle time; we also use BeCu in the center to have better cooling. Normally customers use robots to take out the products to save labor cost. In order to avoid the cost of secondary processing of manually cutting the gate, we use the block with spring to separate the runner and the products, and then the ejector pins eject the products and runners to let them leave the mold.

The most important thing is the polishing of the molds, because disposable tableware is food-grade, products should use high-end polishing. The parting line should be as small as possible to avoid cutting the mouth.