- Home

- >

- Products

- >

- Plastic Crate Mold

- >

- Coke Beer Bottle Crate Mold

Coke Beer Bottle Crate Mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Coke Beer Bottle Crate Mold

Material : HDPE

Mold Cavity:1

Mold Core Steel:BeCu

Mold Cavity Steel: H13+Becu

Mold Injection System:6 tips HR

Mold Size:810 X 940 X 840 mm

Mold weight: 5116 kgs

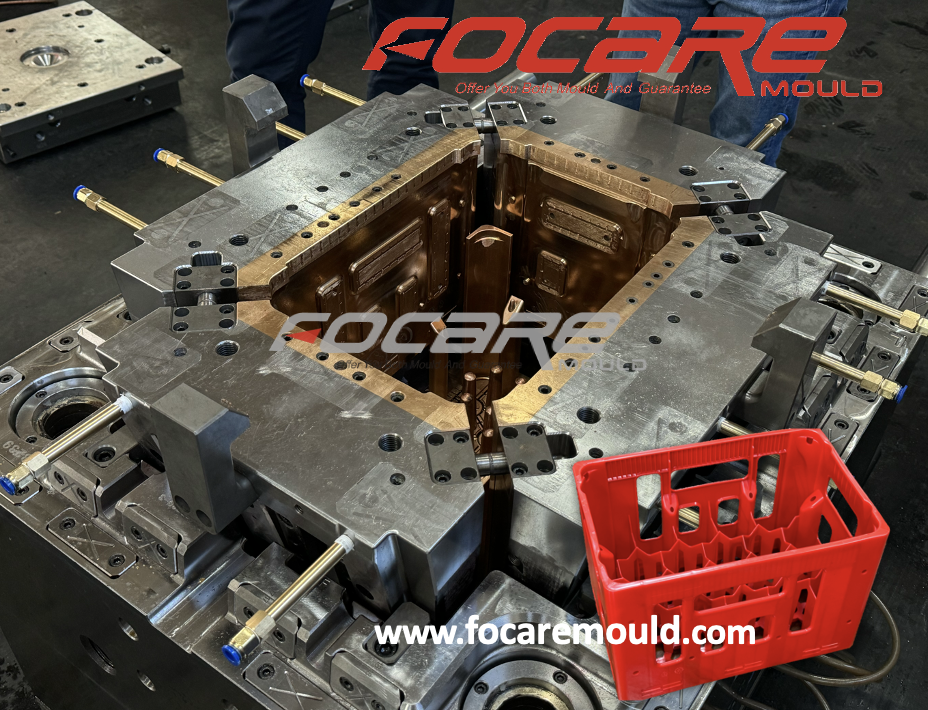

Detail information of Coco Cola Coke Beer Bottle Crate plastic injection mold

Coco Cola Coke Beer Bottle Crate Mold

Material : HDPE

Mold Cavity:1

Mold Steel:BeCu

Mold Cavity Steel: H13+8+4 pillars+Becu

Mold Injection System:6 tips HR (Increased Pin Gate)

Mold Size:810 X 940 X 840 mm

Mold weight: 5116 kgs

Focare Mold has abundant experience in producing coke beer bottle crate plastic injection molds and coke bottle crate plastic injection molds, and provides customers with full forming solutions!

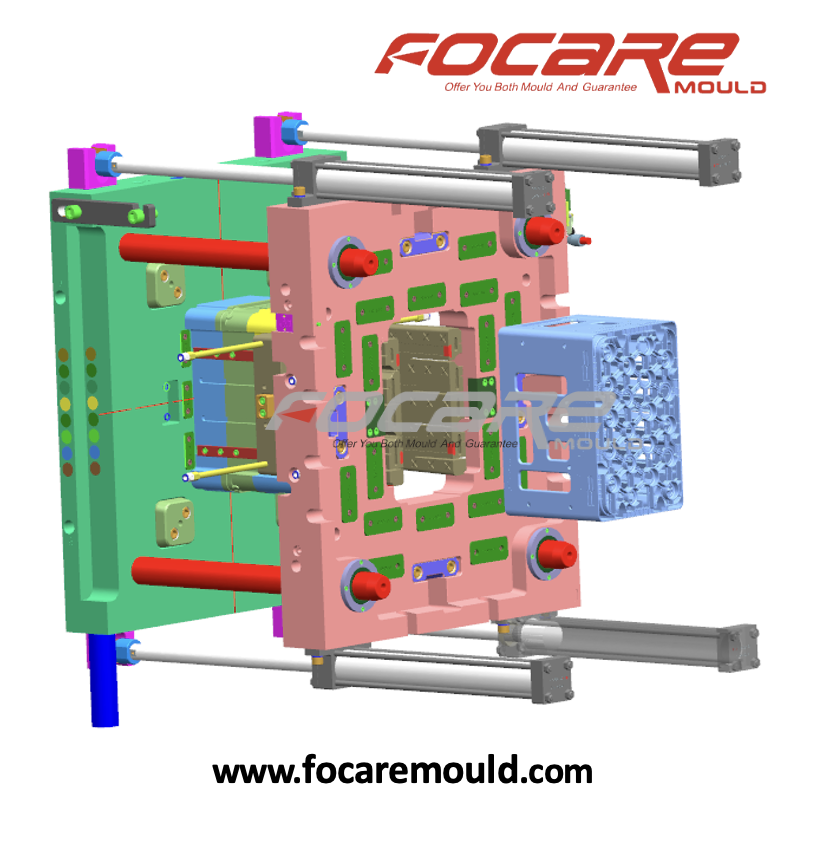

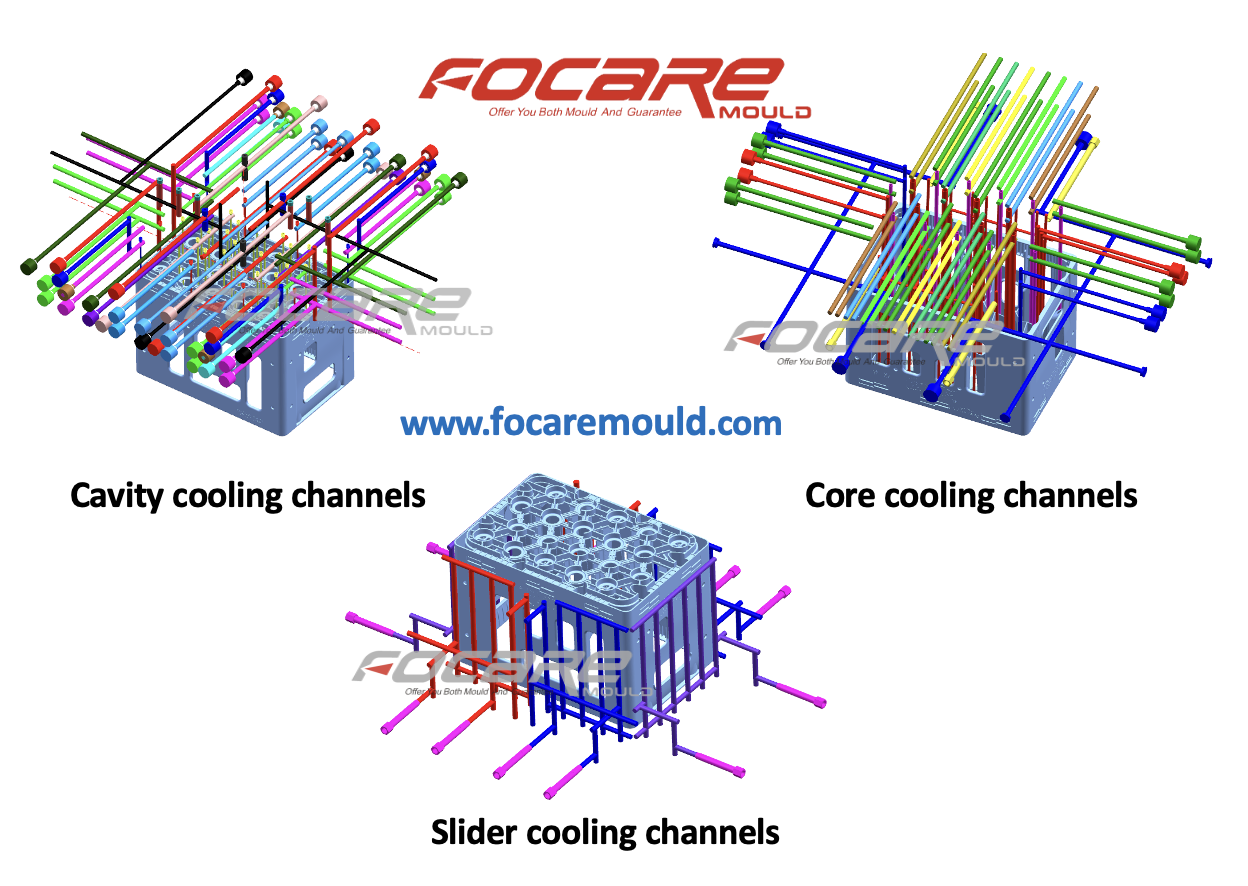

In the production of this kind of coke beer bottle crate plastic injection molds , there are generally four side sliders, four lifters in the core part, one slider connecting rod in each corner of the cavity, and four side walls of the box with the handle of collision.

For this kind of coke beer bottle crate plastic injection molds we can make one or two cavities, the molding cycle time can reach 35 seconds, and the product can be fully automatic demoulding.

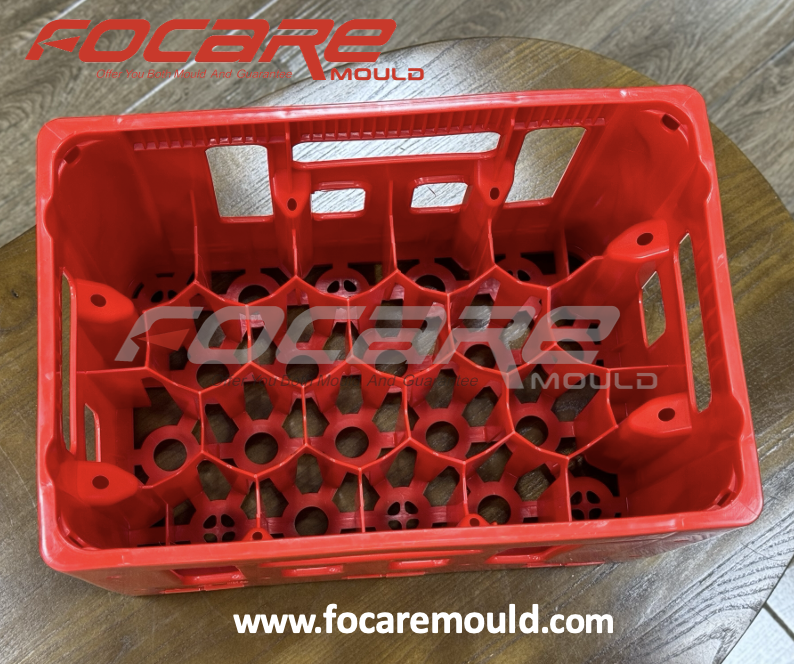

This kind of beer bottle crate is very popular because it can protect the glass bottles from the vibration of the truck and the collision force between the bottles during transportation. Beer bottle crates are generally divided into 12 bottles or 24 bottles a box.

Focare Mould is China professional multi shot mold manufacturer, china mold maker, multi shot injection molding expert.

We can offer you high quality coco cola coke beer crate plastic injection mold.

If you want to make a high quality coco cola coke beer crate plastic injection mold, welcome to contact us.

Our professional team will alway give you more information about coco cola coke beer crate plastic injection mold .

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services