- Home

- >

- Products

- >

- Plastic Cup / Mug / Pitcher / Jug Mold

- >

- Acrylic water pitcher jug cup mold

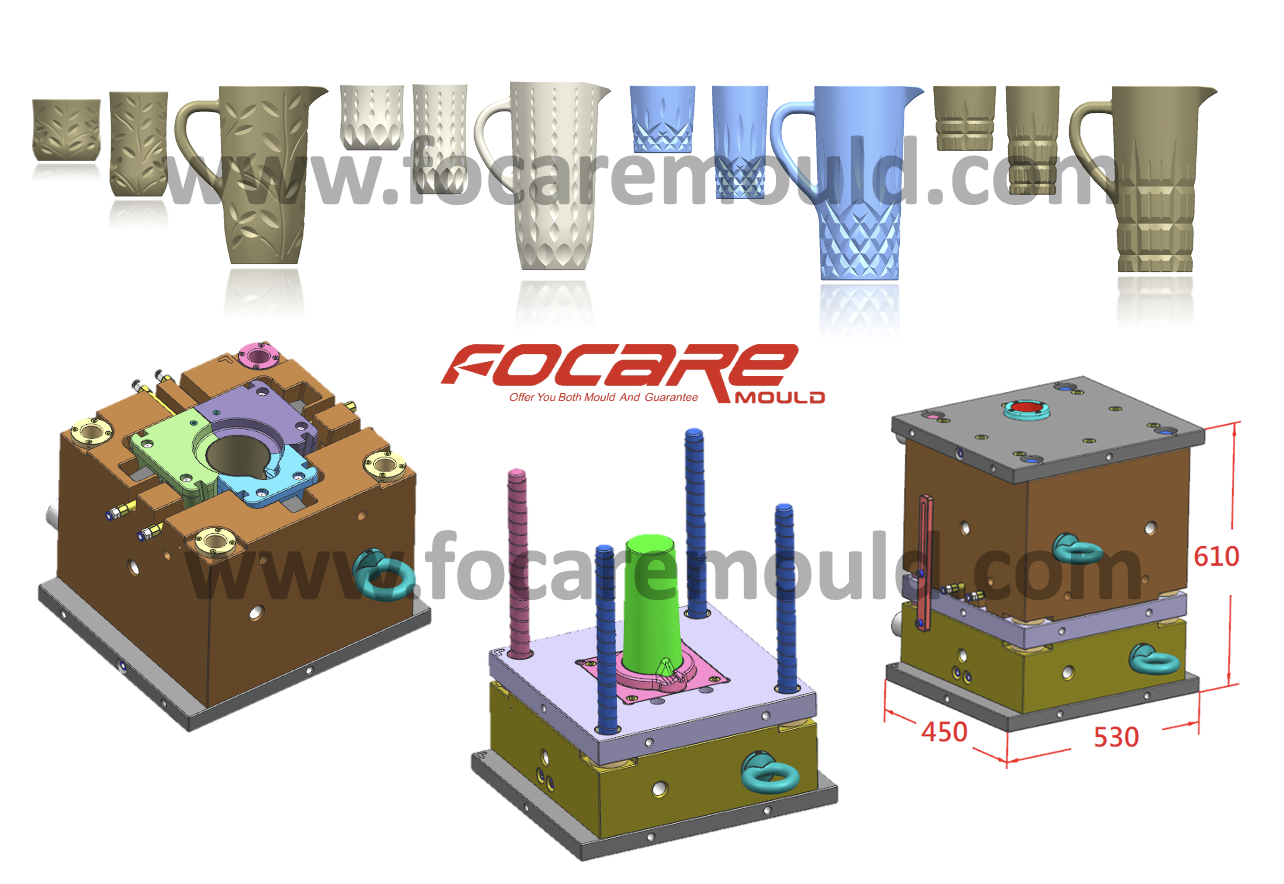

Acrylic water pitcher jug cup mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Product Material: PMMA / Acrylic

Mould Cavity: 1+1

Hot Runner system: 2 tips HR

Mould Steel: H13 with hardness 48-50 HRC

Mold dimensions: 421 X 500 X 551 mm

Mold size: 707 kg

Suggested machine: FCS HT-300

Detail information of acrylic water pitcher jug cup plastic injection mold

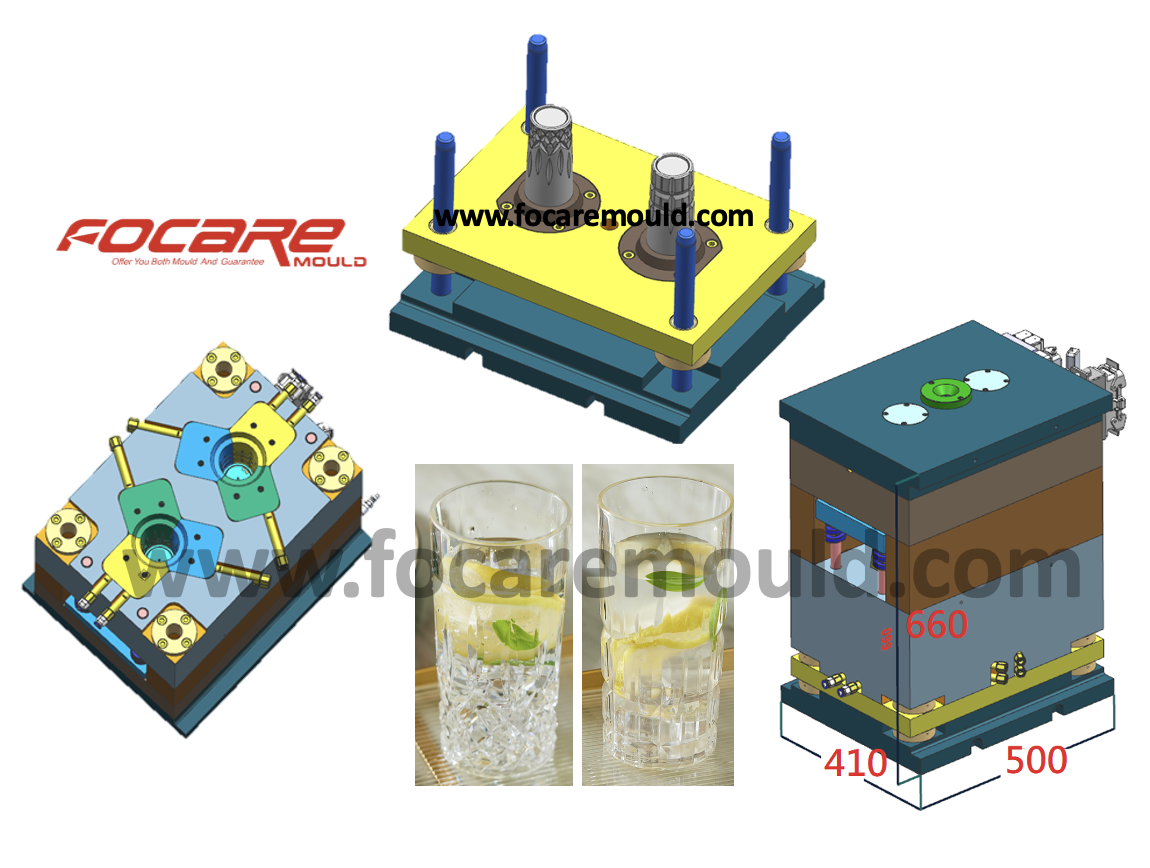

Detail information of acrylic cup mug plastic injection mold (300ml)

Product Material: PMMA / Acrylic

Mould Cavity: 1+1

Hot Runner system: 2 tips HR

Mould Steel: H13 with hardness 48-50 HRC

Mold dimensions: 421 X 500 X 551 mm

Mold size: 707 kg

Suggested machine: FCS HT-300

Detail information of acrylic cup mug plastic injection mold (350ml)

Mould Cavity: 1+1

Hot Runner system: H13 with hardness 48-50 HRC

Mould Steel: 2344

Mold dimensions: 420 X 500 X 620mm

Mold size: 797 kg

Suggested machine: FCS HT-250

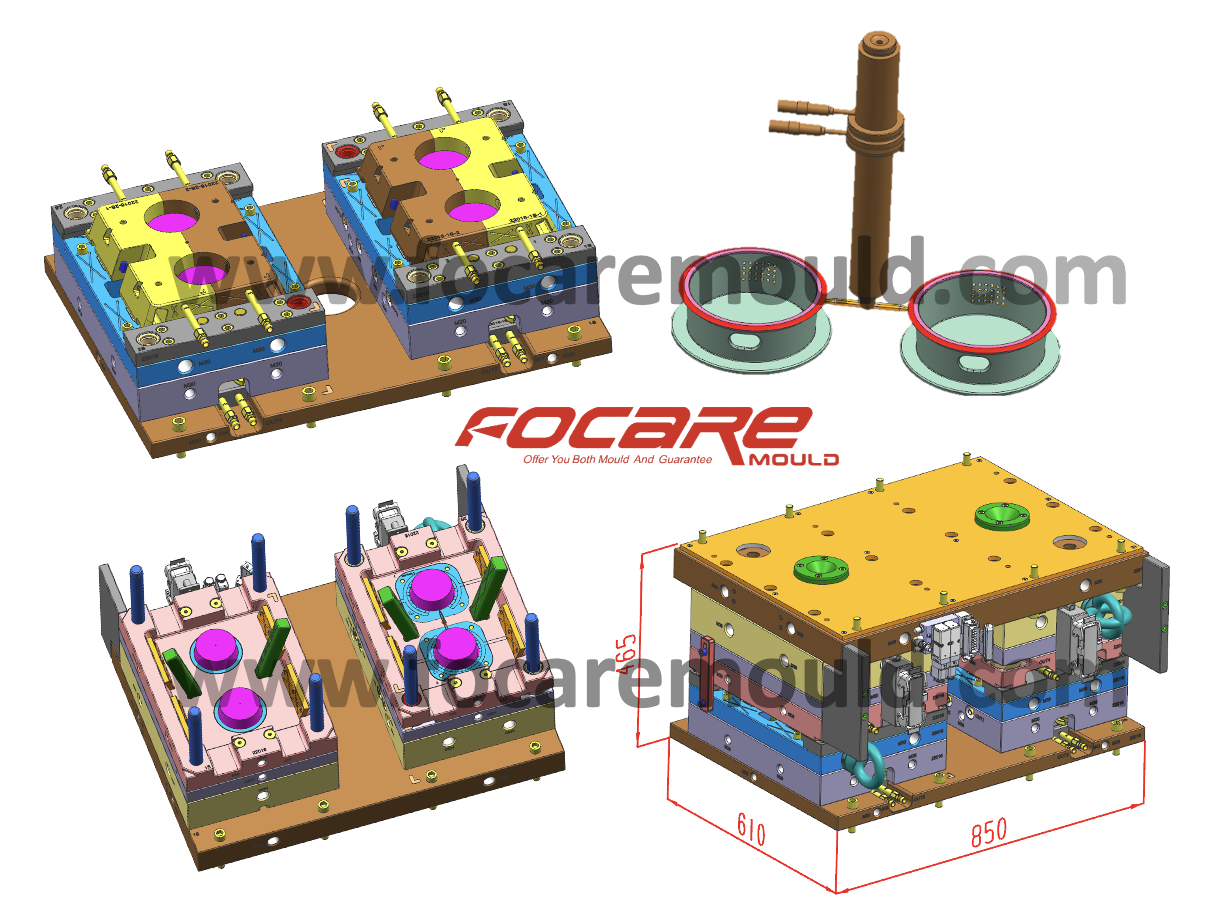

Detail information of acrylic water jug pitcher plastic injection mold (1800ml)

Mould Cavity: 1+1

Hot Runner system: H13 with hardness 48-50 HRC

Mould Steel: 2344

Mold dimensions: 540 X 550 X 612mm

Mold size: 919 kg

Suggested machine: FCS HT-350

Detail information of two color acrylic water jug pitcher lid plastic injection mold (1800ml)

Mould Cavity: 2+2

Hot Runner system: AS: 2 HR valve gate/ TPE: Big gate leads to cold runner side gate

Mould Steel: H13 with hardness 48-50 HRC

Mold dimensions: 850 X 610 X 455mm

Mold size: 1281 kg

Suggested machine: FB-280RV

There are 4 different styles to choose.

Focare Mould is China professional multi shot mold manufacturer,china mold maker, multi shot injection molding expert.

We can offer you high quality Acrylic water pitcher jug cup mold.

If you want to make a high quality Acrylic water pitcher jug cup mold plastic injection mold, welcome to contact us.

Our professional team will alway give you more information about acrylic water pitcher jug cup mold.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services