- Home

- >

- Products

- >

- Household Mold

- >

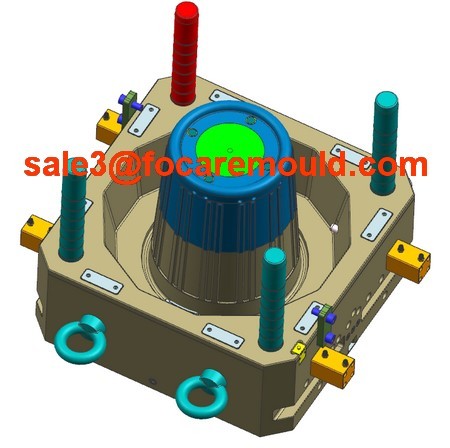

- 200L Dustbin Plastic Injection Mould

200L Dustbin Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

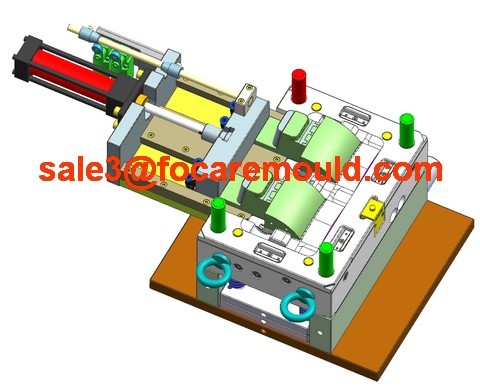

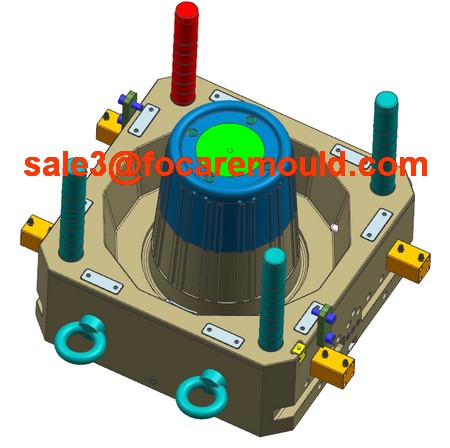

This dustbin is included bucket body, cover and handle. The plastic dustbin is made of recyclable plastic PP through a large injection molding machine, which can be recycled repeatedly. The plastic garbage bin has acid resistance, alkali resistance, corrosion resistance and strong weather resistance.

This dustbin is included bucket body, cover and handle. The plastic dustbin is made of recyclable plastic PP through a large injection molding machine, which can be recycled repeatedly. The plastic garbage bin has acid resistance, alkali resistance, corrosion resistance and strong weather resistance.

Advantages of plastic garbage bins:

1. Since the plastic garbage bin is injection-molded, its fill mouth is designed with rounded corners, there is no burr or flash, it is safer during use, it is not easy to scratch the arm, and the surface is smooth and easy to clean after use.

2. Because the plastic garbage bin is injection molded, the mold can be designed in many styles and colors. The general colors are red, green, orange and yellow. The colors can also be customized according to customer requirements.

3. Since the raw material of plastic garbage bins is plastic, the price of using plastic garbage bins is much cheaper than iron and stainless steel garbage bins.

4. Plastic garbage bins can also be stacked, which can save many transportation costs

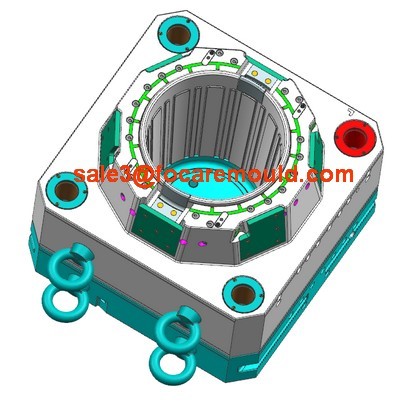

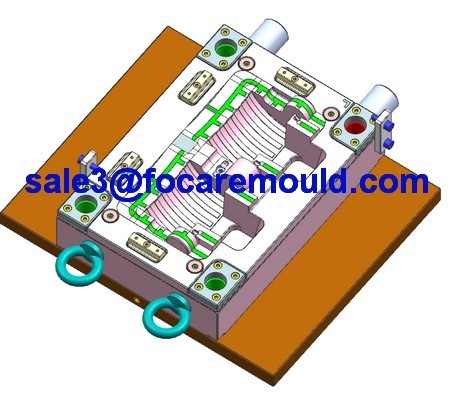

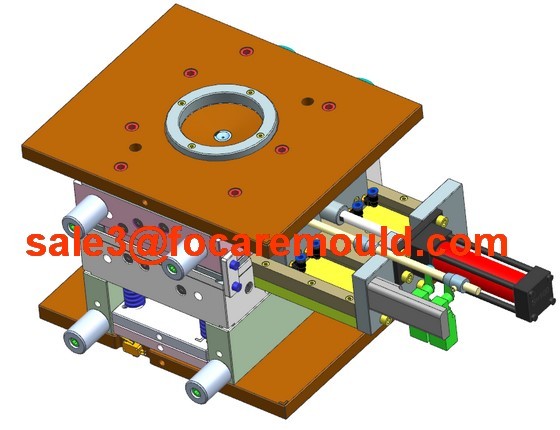

For this 200L garbage bin, we choose to use P20 steel because P20 steel has the following characteristics:

1. Uniform hardness, good polishing performance and photo-etching performance, good processing performance.

2. The vacuum degassing refining process is pure steel, suitable for plastic molds that require polishing or texturing.

3. It is supplied in the pre-hardened state, which can be directly used for mold processing without further heat treatment, shortening the construction period.

4. After forging and rolling, the structure is dense, 100% ultrasonic inspection, no pores and pinhole defects.

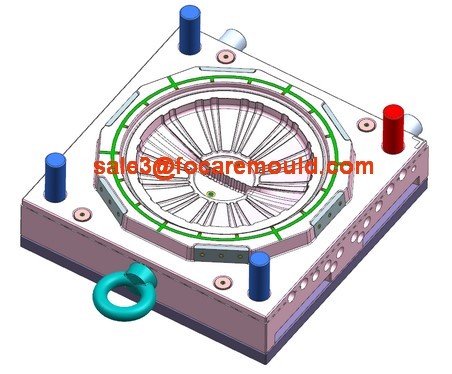

The production requirements of plastic garbage bin molds are very high. Generally, environmentally friendly PP materials are used. They can be printed on a bright surface and then treated with film printing. However, it is not easy to make a good garbage bin. It is necessary to control the quality on the mold, including mold design, cooling system, mold steel, and the injection gate, etc.