- Home

- >

- Products

- >

- Thin-Wall Packaging Mold

- >

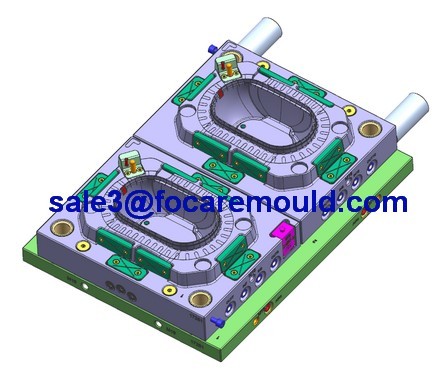

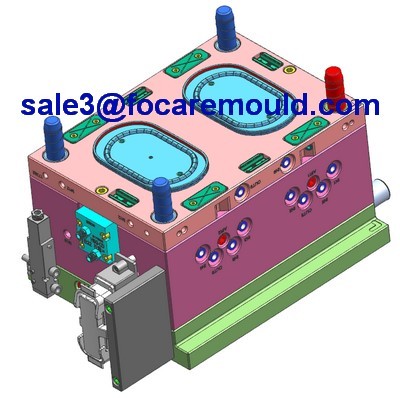

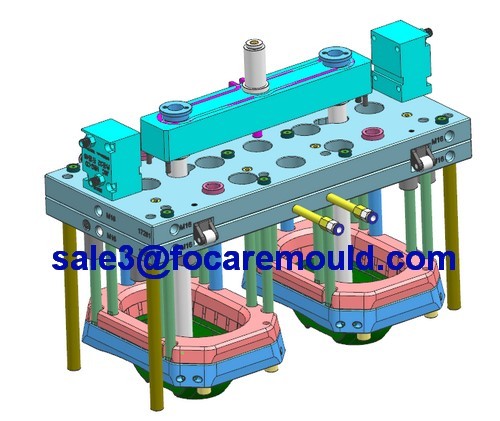

- 1L Ice Cream Oval Thin-Wall Container Mold

1L Ice Cream Oval Thin-Wall Container Mold

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Thin-walled container molds must have high-end polish, as most the fast-food boxes are transparent. That is why we used H13 as the steel material for this thin-walled ice cream box.

H13 steel is the most widely used and representative hot work die steel. Its main characteristics are:

1. It has high harden ability and high toughness.

2. Excellent thermal crack resistance, which can be water cooled in the workplace.

3. With medium wear resistance, carbonizing or Nitrogen processes can also be used to increase its surface hardness, but the thermal crack resistance should be slightly reduced.

4. Due to its low carbon content, the secondary hardening ability is poor in tempering.

5. It has anti-softening ability at higher temperatures, but the hardness will decrease rapidly when the use temperature is higher than 540 ° C (1000 ° F) (that is, the working temperature can be 540 ° C).

6. Small deformation during heat treatment.

7. Medium and high machinability.

8. Medium decarburization resistance.

As consumers pay more and more attention to food safety, polypropylene products are more and more widely used in food packaging and other fields. It is understood that disposable food boxes are easy to use, cheap, and have broad market prospects. Among them, polypropylene disposable food boxes have the advantages of health, environmental protection, beautiful and practical and high cost performance, and are gradually replacing other materials of food boxes. And high fluidity injection molding polypropylene, because of its short processing cycle and good profit, has also become one of the development trends of high-end polypropylene. The domestic demand for thin-wall polypropylene special materials will also increase, and the market prospects and economic benefits are good.

The injection molding process of disposable thin-walled food box molds is relatively difficult, and the mold requirements are very strict. Because the market demand for disposable fast-food boxes is huge, the molds quality must be good, so that the molds can withstand the high production.

Secondly, thin-walled container molds must have high-end polish, as most the fast-food boxes are transparent. That is why we used H13 as the steel material for this thin-walled ice cream box.

H13 steel is the most widely used and representative hot work die steel. Its main characteristics are:

1. It has high hardenability and high toughness.

2. Excellent thermal crack resistance, which can be water cooled in the workplace.

3. With medium wear resistance, carburizing or Nitrogen processes can also be used to increase its surface hardness, but the thermal crack resistance should be slightly reduced.

4. Due to its low carbon content, the secondary hardening ability is poor in tempering.

5. It has anti-softening ability at higher temperatures, but the hardness will decrease rapidly when the use temperature is higher than 540 ° C (1000 ° F) (that is, the working temperature can be 540 ° C).

6. Small deformation during heat treatment.

7. Medium and high machinability.

8. Medium decarburization resistance.