- Home

- >

- Products

- >

- Caps Mold

- >

- Flip-Top Caps Mold

- >

- 16-cavity 20mm Double Color Flip Top Cap Mould

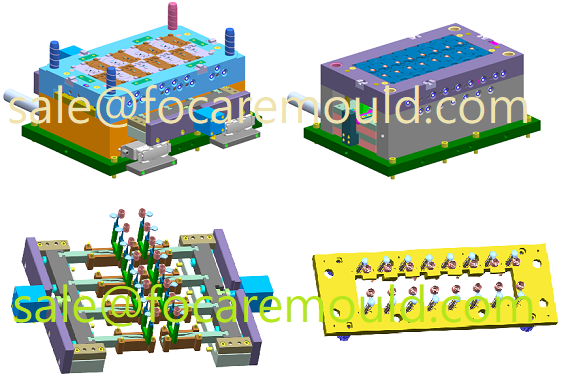

16-cavity 20mm Double Color Flip Top Cap Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Once again Focare Mould has successfully made another two-color flip top injection mold. It is really difficult to make two-color flip top cap mold especially for 16 cavities. Especially, the diameter of two-color cap is only 20mm and the connection between two materials is so tiny. It is arduous to adjust the connection well completely for 16 cavities. In order to achieve this goal, we must not only have professional mold technology, but also have technical injection molding skill. Focare Mould has its own team in mold design, mold making and injection molding. We have two sets of two-color injection molding machines which permit us to test two-color injection molds and help to train our customers’ engineers when it is necessary.

Flip top caps are generally used for shampoo bottles, cosmetic bottles and detergent bottles. The technical key-point of flip top cap mold is closure quality and no water leakage. Meanwhile, the connection between cap base and flip top cap is also critical issue of flip top cap mold. The plentiful experience of flip top cap molds on both product design and mold design become very important.

Single color flip top cap mold is not easy, two-color cap is more difficult. The connection between two-colors is very important for quality of two-color flip top cap. If the connecting bridge didn’t make well, it will be easy cracking and broken. The elasticity of flip top cap is also critical issue required by customers. The top cap shall be opened at the specifying position. Most of flip top caps are made by polypropylene (PP), the shrinkage is not easy to control, and therefore, mold design and manufacturing are very important issues for quality of flip top cap molds.

The diameter of flip top cap is small, it is not easy to design with mold cooling system. There are some ribs inside cap, the steel quality is one of key-points for the flip top cap mould quality. The outward appearance of cap is not allowed to have injection point or ejecting mark, hence, the flip top cap mold design become more complicate which is required to have good experience on design and fabrication.