-

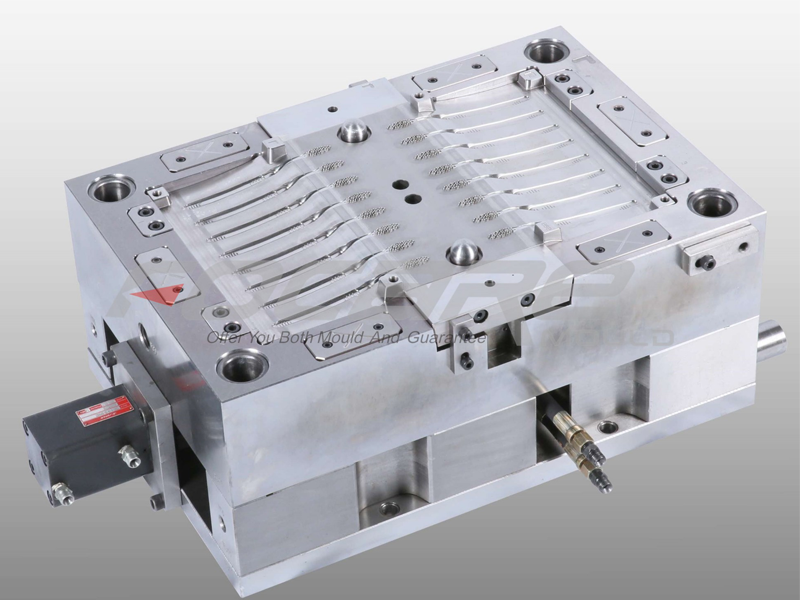

Multi-Color-Rotary Axis

Most of two-color handles are made by rotary axis plastic injection moulds. Rotary axis process or rotary core process means that the two-color plastic injection mould won't rotate by injection machine, however, the cores of mold will be rotated by injection machine or cylinder of injection mould. When the injection part will be made the second color, the controller of injection machine will deliver signal of core pulling system to rotate the 1st core of mould to second position of core, then make the second color injection.

Read More -

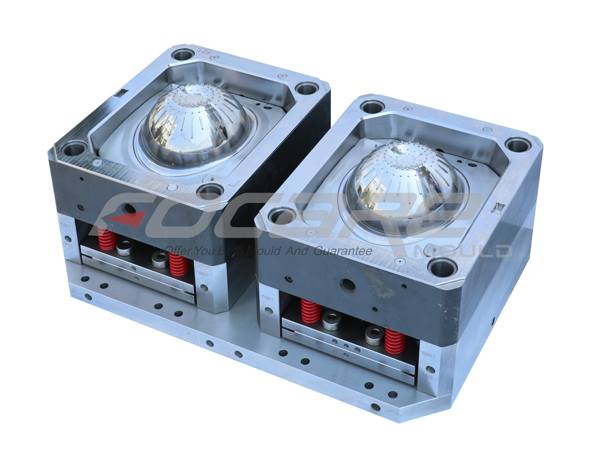

Multi-Color-Rotary Table

What is two-color plastic injection mould? Two-color or two plastic materials or two components are injected on one machine, molded by two different molds, it is called two-color molding. The two-color plastic injection molds are required special design of two-color injection machine with rotary table or rotary axis, or only two injection carriage. The investment of two-color molds and two-color injection machines is higher than conventional single color molds and single color machine, however, the high quality of plastic products and precise technology on both two-color molds design and high technical adjustment of injection parameters are not easy to be copied or launched into same business.

Read More -

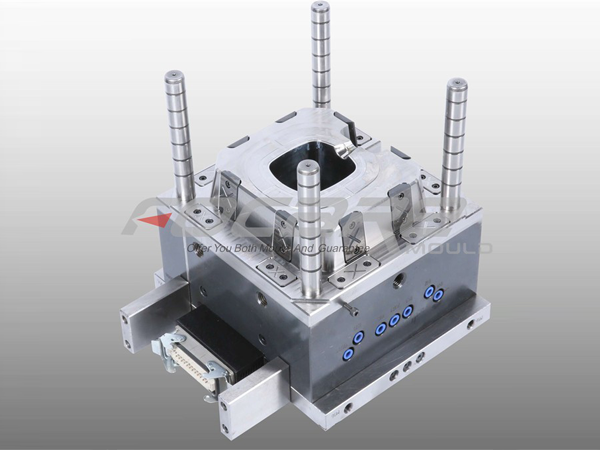

Multi-Color-Over Molding

Two-color over molding process is the lower investment for making two-color plastic products. For some bigger size two-color products or two-color plastic parts with lower market demand, it is not economic to invest two-color injection machine and two-color injection molds. Two-color over molding process is the best choice for making two-color plastic products.

Read More