- Home

- >

- News

- >

- Company News

- >

- What are the advantages for double-color injection moulds

What are the advantages for double-color injection moulds

Everyone knows that the quality of two-color plastic injection products made by two-color moulds is better than made by two sets of sing-color moulds. However, the cost of single color plastic injection moulding on each machines, molds and manufacturing is lower than the one of double color injection. Therefore, most of maker hesitate to invest double color injection moulds and machines.

On the other hand, the required technology of single color plastic injection is not high as double color injection, the plastic products look not so high-end so that the selling price is more competitive. Someone decided to use two sets of sing-color moulds for making double-color plastic products.

Regarding to this kind of process, it is necessary to have double space and labor cost for accommodating and operating two injection machines. The most important things are the timing and plastic material for making second injection molding. If the timing could not control well, it is not easy to get good two-color plastic products.

The advantage of double-color injection molds is the two-color products could be made at the same time. Except for less production space and lower labor cost, the most important thing is few defectives and high injection productivity which could reduce the unit cost, increase the quality of two-color injection products and rise the selling competiveness up.

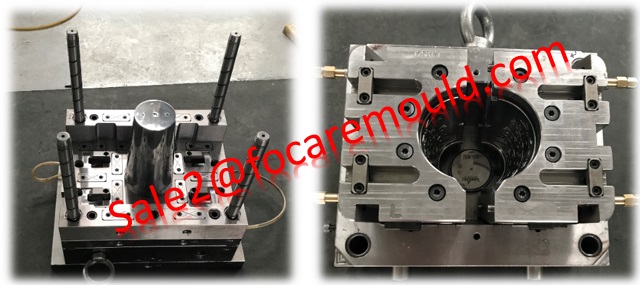

Of course, the technical skill and experience on making double-color injection molds are very important for making two-color plastic injection parts. The experienced two-color moulds design is key-point to make workable double-color moulds, machinery precise is strongly required on fabricating molds cores and cavities. The qualified engineer on making adjustment of injection parameter is also quite important on making two-color plastic injection moulds.