-

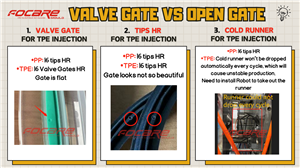

Valve Gate vs Open Gate in Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. Among the various components and technologies involved in injection molding, the gating system plays a crucial role in determining the quality and characteristics of the final product. Two primary gating methods are valve gate and open gate systems. Understanding the differences between these two systems is essential for selecting the appropriate method for specific applications.

Read More -

Application of (Becu) beryllium copper in plastic mould

Beryllium copper Becu is often used in plastic injection molds due to its unique combination of properties that make it well-suited for this application.

Read More -

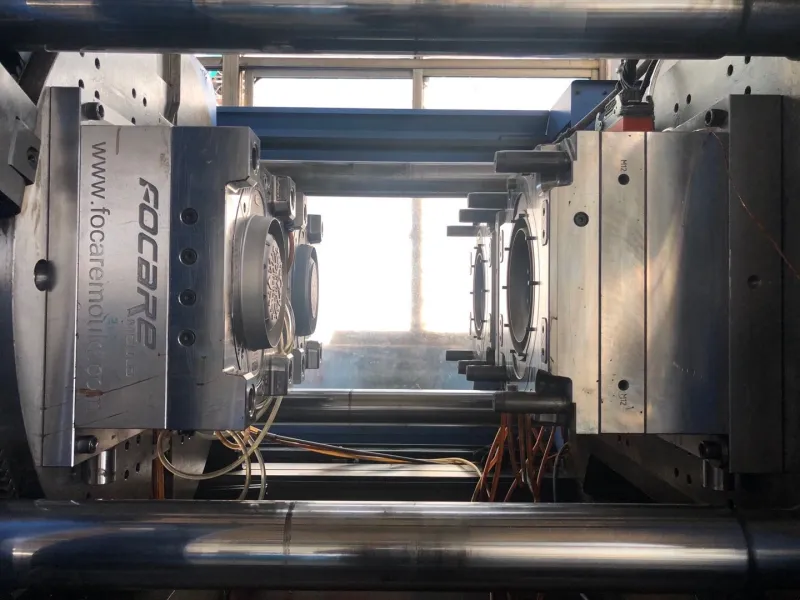

Focare Mould: Unleashing the Advantages of Choosing a China Mold Maker

Collaborating with a China mold factory provides the flexibility, customization, and value required to succeed in today's competitive market. As the manufacturing landscape continues to grow, the expertise and services of China mold makers will play a pivotal role in shaping the future of various industries.

Read More -

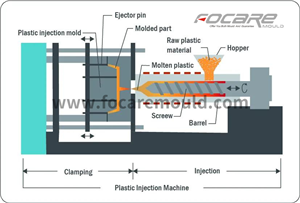

What is mold / injection molding ?

The mold consists of two primary components, the core side (fixed mold) and the cavity side (moving mold). Plastic material enters the mold through a sprue or gate in the injection mold; the sprue bushing is to seal tightly against the nozzle of the injection barrel of the molding machine and to allow molten plastic to flow from the barrel into the cavity. As the material cools, it will solidify into the shape of the cavity and become the desired part. When the mold is opened, the cavity side and the core side are separated to take out the plastic products.

Read More -

How to make a good mold? Why is a mold so expensive?

A good mold should produce high-quality products, should help manufacturer to save time and cost to create higher efficiency, and should have long mold life, low damage rate.

Read More -

Things you must know about injection molding

The injection molding process requires the use of an ”injection molding machine”, ”raw plastic material”, and a ”mold”. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part. The steps in this process are described in greater detail in the next section.

Read More

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.