-

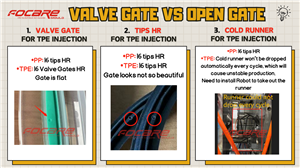

Valve Gate vs Open Gate in Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. Among the various components and technologies involved in injection molding, the gating system plays a crucial role in determining the quality and characteristics of the final product. Two primary gating methods are valve gate and open gate systems. Understanding the differences between these two systems is essential for selecting the appropriate method for specific applications.

Read More -

What is mold / injection molding ?

The mold consists of two primary components, the core side (fixed mold) and the cavity side (moving mold). Plastic material enters the mold through a sprue or gate in the injection mold; the sprue bushing is to seal tightly against the nozzle of the injection barrel of the molding machine and to allow molten plastic to flow from the barrel into the cavity. As the material cools, it will solidify into the shape of the cavity and become the desired part. When the mold is opened, the cavity side and the core side are separated to take out the plastic products.

Read More -

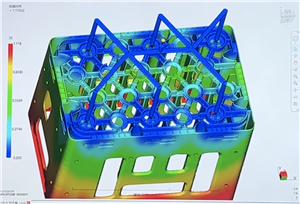

What is mold flow analysis (MFA) ?

Taking your mold from good to great is as simple as testing it via Mold Flow Analysis (MFA). This software simulates your mold conditions before you open up your wallet to pay for tooling. The effect MFA has on the quality of the mold, the performance and appearance of your product makes it an indispensable component of any plastic injection molding design project.

Read More

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.