- Home

- >

- Products

- >

- Kitchenware Mold

- >

- Two Color Utensil Handle Mold

- >

- Two-Color Plastic Salad Spoon & Fork Injection Mould

Two-Color Plastic Salad Spoon & Fork Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

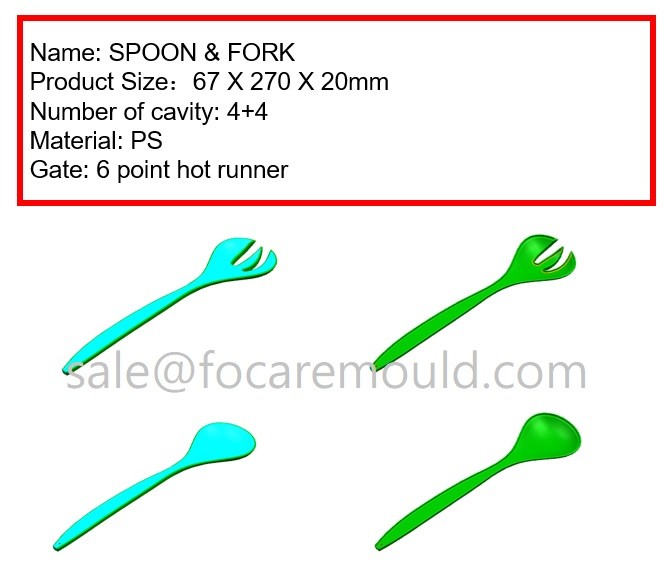

This two-color salad spoon & fork are ideal for catering, food service, picnics, weddings, buffets, family reunions and everyday use.

It is made by two colors of Polystyrene (PS). The special character of Polystyrene is naturally transparent which let plastic housewares look like crystal, shiny and high-end quality. Also, it could be colored with color master, the plastic products will be more shiny colorful.

This two-color salad spoon & fork are ideal for catering, food service, picnics, weddings, buffets, family reunions and everyday use.

It is made by two colors of Polystyrene (PS). The special character of Polystyrene is naturally transparent which let plastic housewares look like crystal, shiny and high-end quality. Also, it could be colored with color master, the plastic products will be more shiny colorful.

The outer green part is made by first injection, then make the second injection upon inner white part.

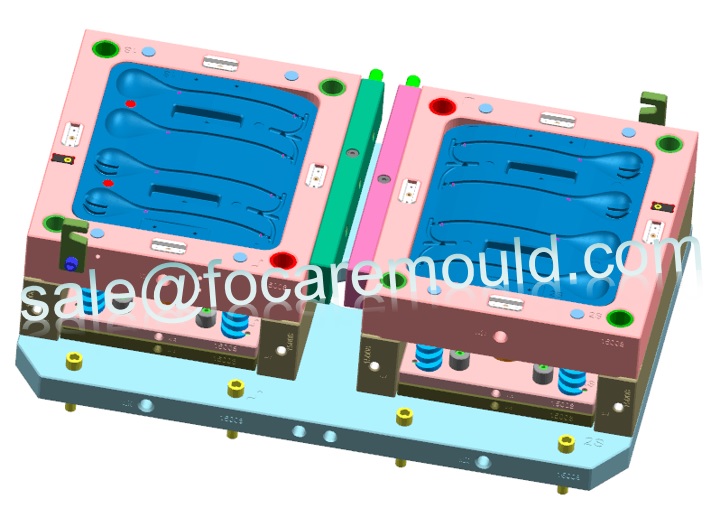

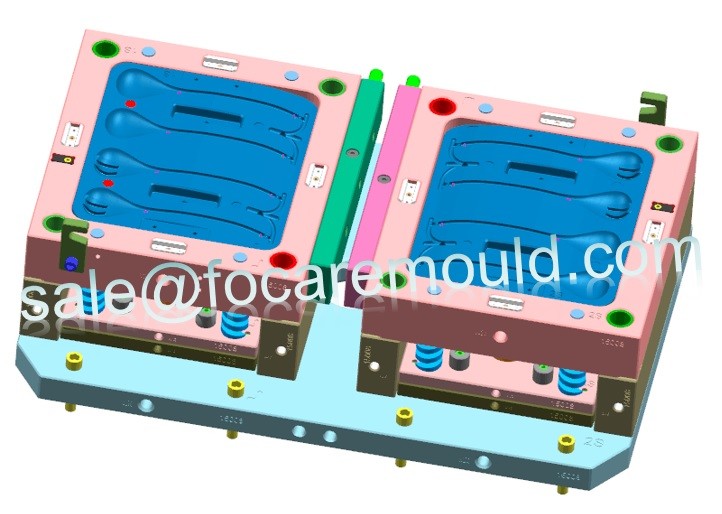

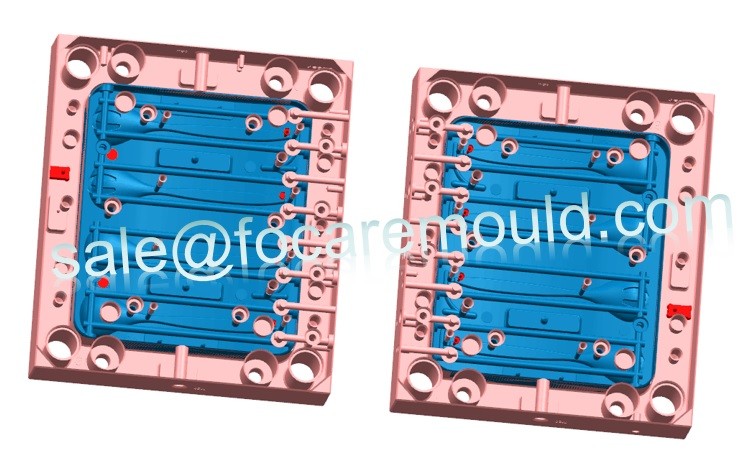

This two-color injection mould is combined two different products, fork and spoon which weight and shape are different. Hence, mold flow analysis is very important before fabricating injection mould. Moreover, the parting line between two colors is also the key-point for making smooth edge and well touching.

Two-color plastic products traditionally are made by two-step injection moulding procedure which inner part and outer part are made by two different injection mould machine at different time. The advance of this conventional injection procedure is only for consideration of equipment cost. In fact, it is not easy to control the quality of two-color combination. The second part will be easy to have flash if the point-in-time of shrinkage for the inner part was different for each shot. Meanwhile, it will take time on inserting the inner parts into mold cavities and positioning at precise place of cavities during over moulding.

In order to make two-color plastic products with less defective, makers are suggested to consider double color injection moulds and double color injection machines and make the two-color products at once. It is not only for getting perfect two-color injection products, but also land space saving and lower labor cost.