- Home

- >

- Products

- >

- Baby Use Mold

- >

- Two-color non-slip potty training seat plastic injection mold

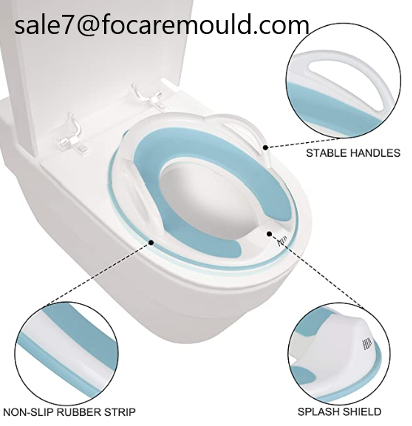

Two-color non-slip potty training seat plastic injection mold

Manufacturers are suggested to use bi-injection way to produce two-color non-slip potty training seat, which may make products with better appearance and helps save time and manufacturing cost a lot. However, the traditional way: over-molding is appropriate for manufacturers who have single-color plastic injection machine only. Either produce products by bi-injection or over-molding, the molds should have high quality and precision to ensure the production being smoothly and efficiently. Welcome to contact us, we are experienced, professional and reliable.

As the standard toilet is too big for children, adding potty training seat on the toilet is the easiest and convenient way to train children. The new design of potty training seat is made by PP and TPE, which makes the product light, waterproof, and easy to clean. The TPE part on the top makes children to have a soft and comfortable using experience, and the part under the seat creates the effect of non-slip. The characteristics of two-color non-slip potty training seat are:

1. Safe and antibacterial: Made by legal material PP and TPE, the two-color non-slip potty training seat is antibacterial, mildew proof, non-toxic, BPA free, and phthalate free. Parents can use it with confidence.

2. Light weight, durable material: The potty training seat is light but strong, portable, and has long service life. Children can place it on the toilet, and put the seat back to hook by themselves easily.

3. Ergonomic design: Ergonomically designed for children comfort and safety.

4. Handle design: Children can climb up and off the toilet easier with handle. With the secure and stable feeling, children gain confidence.

5. Splash guard design: The splash guard design prevents urine from spilling out, which helps parents to keep the bathroom clean.

6. Non-slip design: Maintain the seat in right position, which significantly increases the safety.

Manufacturers are suggested to use bi-injection way to produce two-color non-slip potty training seat, which may make products with better appearance and helps save time and manufacturing cost a lot. However, the traditional way: over-molding is appropriate for manufacturers who have single-color plastic injection machine only. Either produce products by bi-injection or over-molding, the molds should have high quality and precision to ensure the production being smoothly and efficiently. Welcome to contact us, we are experienced, professional and reliable.