- Home

- >

- Products

- >

- Plastic Crate Mold

- >

- Plastic Beer Crate Injection Mould

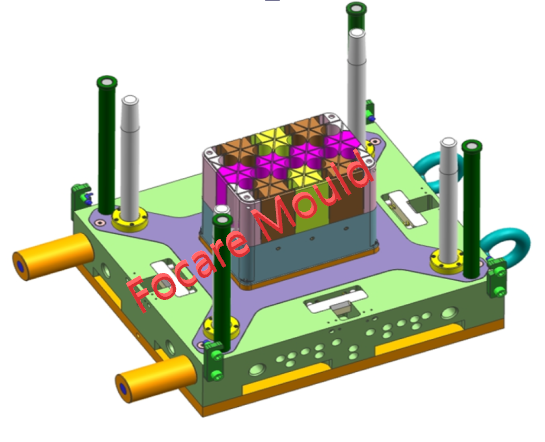

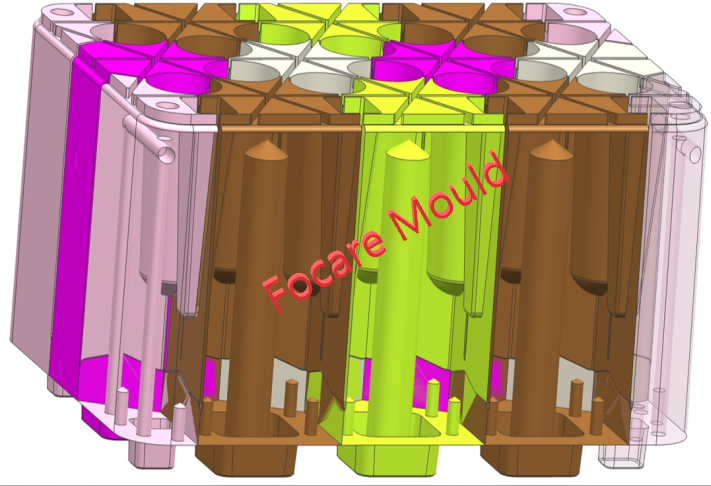

Plastic Beer Crate Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Beer crate

1. 12 bottles: 360 * 275 * 316mm

2. 20 bottles: 450 * 365 * 315mm

3. 24 bottles: 530 * 360 * 320mm

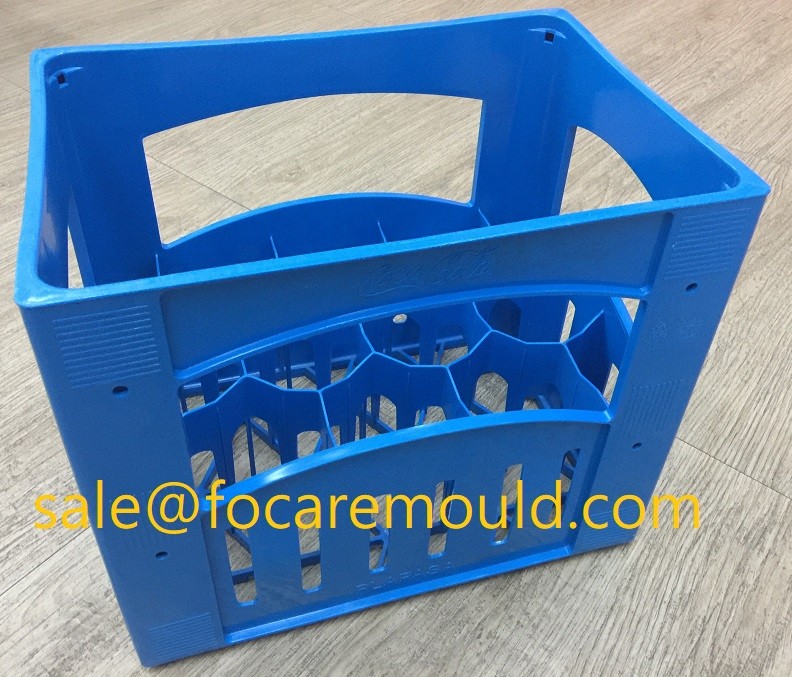

It is made of 100% high-density polyethylene (HDPE) for injection molding. It has the characteristics of heat resistance, cold resistance and corrosion resistance. It can withstand high temperature up to 120 degrees and low temperature resistance to minus 30 degrees. And the appearance is smooth, no burrs, and durable!

Plastic crate is made of 100% high-density polyethylene (HDPE) for injection molding. It has the characteristics of heat resistance, cold resistance and corrosion resistance. It can withstand high temperature up to 120 degrees and low temperature resistance to minus 30 degrees. And the appearance is smooth, no burrs, and durable!

Below is some of the PLASTIC CRATE IMPACT TEST WAYS:

PLASTIC CRATE IMPACT TEST

CRATE TM 1-6

-----------------------------------------------------------------------------------------------------------------

OBJECTIVE

To determine the ability of the plastic crate to withstand a dynamic (impact) load.

PRINCIPLE

During the distribution cycle, the plastic crates may be dropped and/or have objects dropped on to them.

The crates need to be capable of sustaining multiple drops or impacts during its useful lifespan.

APPARATUS

1. LDPE bottles of nominal diameter of the intended bottles.

Bottles to be filled with sand (corresponding to the fill weight with products) and are to be capped.

2. 600mmx600mmx12mm. (nominal 24 in. x 24 in. x 0.5 in.) steel plate (in intimate contact with concrete floor.

3. Device for releasing sample crates so that they impact Swing leaf drop tester capable of 4 meter drop height.

4. Laboratory Balance 4,000 gm Capacity + 0.1 gm accuracy.

5. Go-No Go gauge for partition size? (gauge to have diameter equal to the maximum diameter (inclusive of tolerances)

of the bottles to be utilized in the plastic crates.

Go-No Go gauge for partition size?

【Note: Weight to be equal to the gram weight of the bottle to be utilized in the crates】.

6. Temperature and humidity controlled chamber set for 20℃/50% RH ±1.0℃/5%RH

SAMPLE QUANTITES

Six 【6】samples.

PROCEDURE

1. Place the test specimens in the 20℃/50% RH test chamber for a minimum of forty-eight【48】hours after products

2. Fill each bottle to the nominal content weight with sand and cap.

3. Place one filled bottle in each cavity of the crate.

4. Drop the filled sample crates individually onto the steel plate from a height of 4 meters (measured from the bottom of the crate)

5. Observe the effect of the impact and note damage if present.

6. Drop the crate an additional three 【3】times, noting any damage between drops.

7. Try to insert the bottle gauge in each of the cavities (for all three【3】crates in the stack

(note any cavities in which the gauge does not traverse to the bottom under the action of gravity)

1. Record the data on worksheet for this test method or equivalent (see FORMS section of this manual)

2. Quantity of samples tested.

3. Any and type of damage which occurs.

PLASTIC CRATE IMPACT TEST

CRATE TM 1-7

OBJECTIVE

To determine the interlocking feature and ability to withstand vibrational and repetitive shock loads.

PRINCIPLE

During shipment, overland, rail and transport, vibrational inputs.

APPARATUS

1. LDPE bottles of nominal diameter of the intended bottles

2. Bottles to be filled with sand (corresponding to the fill weight with products) and are to be capped.

3. Shaker Table with vertical movement of 14.28mm, horizontal movement of 6.35 mm and a frequency of 4 Hz. with padded divider in place to separate the four 【4】individual stacked sets of crates.

4. Temperature and humidity controlled chamber set for 20℃/50% RH ±1.0℃/5%RH

SAMPLE QUANTITES

Eight 【8】samples.

PROCEDURE

1. Place the test specimens in the 20℃/50% RH test chamber for a minimum of forty-eight【48】hours after products

2. Fill each bottle to the nominal content weight with sand and cap.

3. Place one filled bottle in each cavity of the crate.

4. Arrange the crates on the top of the shaker tables as follows:

a. Make four 【4】stacked sets two 【2】crates high.

b. Place two 【2】of the sets with the long sides parallel to the horizontal oscillator

c. Place two 【2】of the sets with the long sides parallel to the horizontal oscillator

5. Ensure the divider is properly installed and the individual stacked sets can not come in contact with each other.

6. Initiate the testing cycle and apply the vibrational input for a one 【1】hour period

7. Inspect the crates for damage

REPORT

1. Record the data on worksheet for this test method or equivalent (see FORMS section of this manual)

2. Quantity of samples tested.

3. Any and type of damage which occurs.